Method for preparing ethylene sulfate

A technology of vinyl sulfate and vinyl sulfite, which is applied in the field of preparation of vinyl sulfate, can solve the problems of unresolved purity and yield, difficult availability of product raw materials, and impossibility of industrial production, etc., to achieve reduced oxidation time and low moisture content , reduce the effect of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

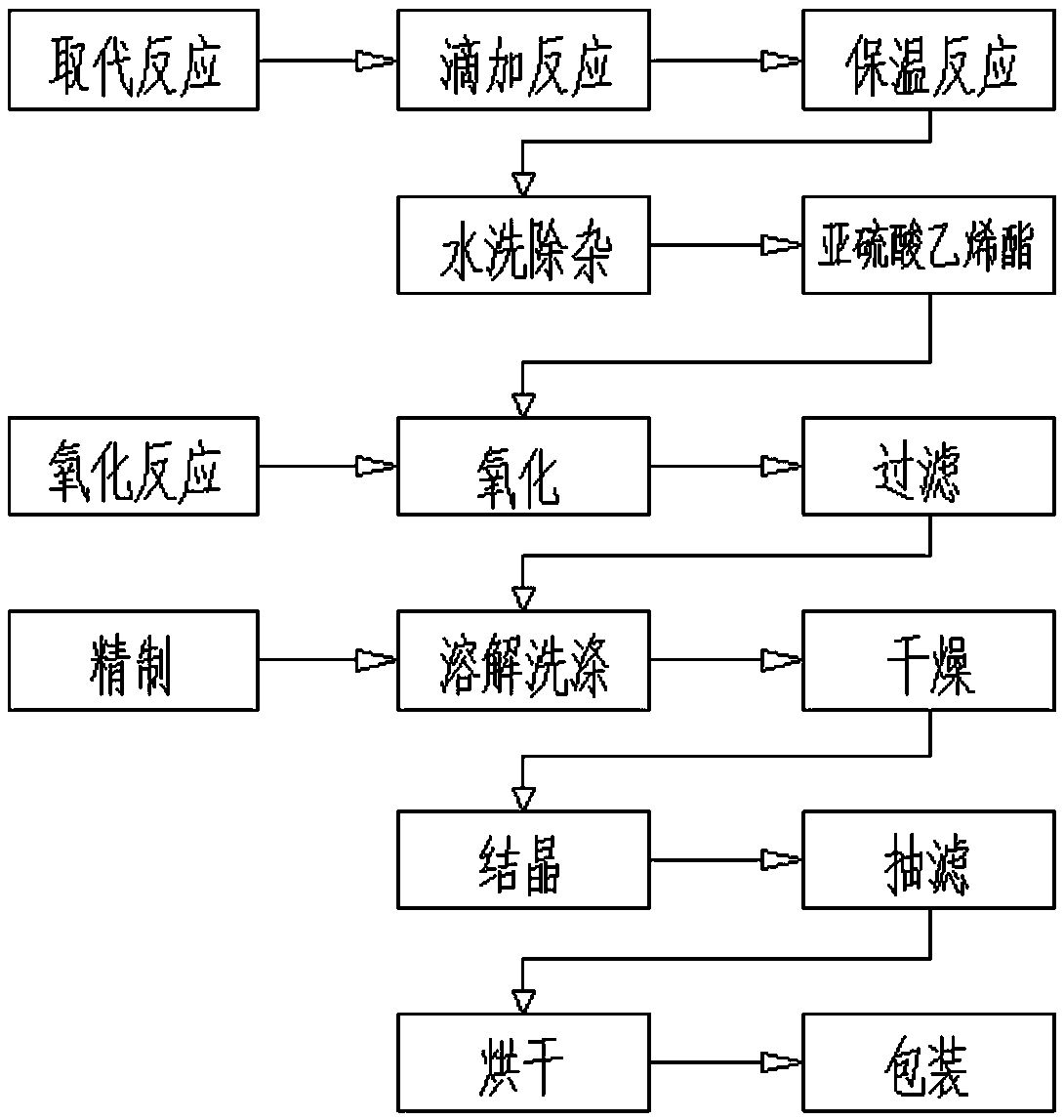

[0034] The preparation method of vinyl sulfate mentioned in the present invention, its detailed preparation method, comprises the following steps:

[0035] (1) Add ethylene glycol into the reaction kettle, then slowly add thionyl chloride dropwise to it, and control the reaction temperature at 25-30°C;

[0036] (2) After the dropwise addition is completed, raise the temperature to 40°C, keep it warm for 1 hour, continue to raise the temperature to 50°C, and keep it warm for 2 hours;

[0037] (3) After the heat preservation is over, cool to room temperature, add deionized water to the obtained solution for washing, and add sodium carbonate solution to adjust the pH value to neutral, let stand for a period of time, and separate vinyl sulfite after layering solution;

[0038] (4) Put the vinyl sulfite obtained above into the oxidation kettle, and add ice cubes to control the initial temperature at 0-5°C;

[0039] (5) Add buffering agent to the oxidation kettle to adjust the pH ...

Embodiment 1

[0049] Embodiment 1: the preparation method of vinyl sulfate mentioned in the present invention comprises substitution reaction, oxidation reaction and refining process, and concrete steps are as follows:

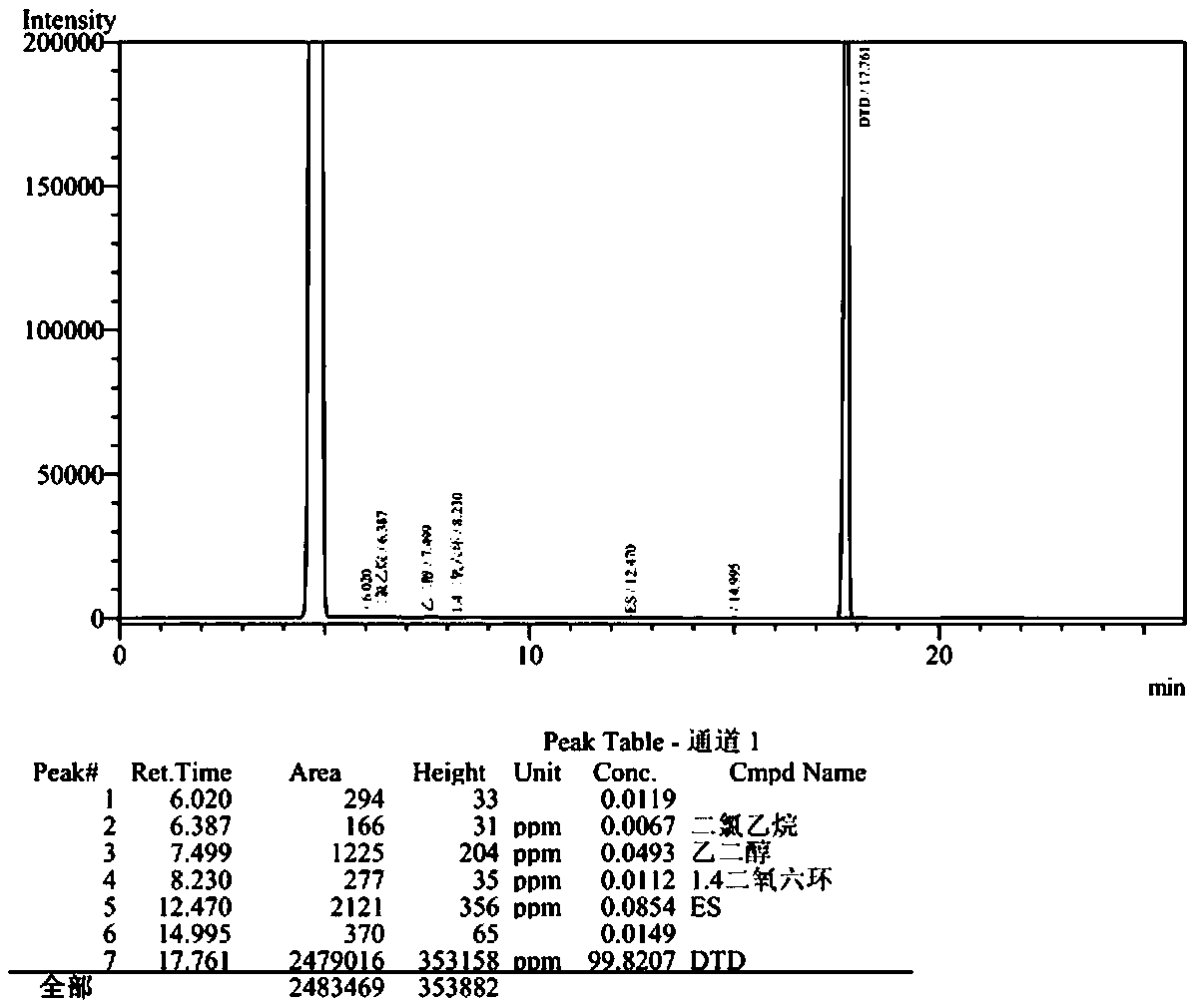

[0050] (1) Substitution reaction: Thionyl chloride and ethylene glycol are used as the reaction raw materials for the substitution reaction. First, 1325g (10mol) of ethylene glycol is added to the reaction kettle, and then chlorine is added dropwise to the first reaction kettle at room temperature. 3012g (12mol) of sulfoxide, the dropping time is 1h, and the dropping temperature is controlled at 28°C. After the dropwise addition, keep the temperature at 40°C for 1 hour, then increase the temperature to 50°C, and keep the temperature for 2 hours. Thereby obtain the reaction solution containing vinyl sulfite, wash the reaction solution with deionized water, then leave the reaction solution, layered and separate vinyl sulfite 2413g (purity is 98.92%), then separate the Vinyl ...

Embodiment 2

[0053] Embodiment 2: a kind of vinyl sulfate preparation method is: comprise substitution reaction, oxidation reaction and refining process, concrete steps are as follows:

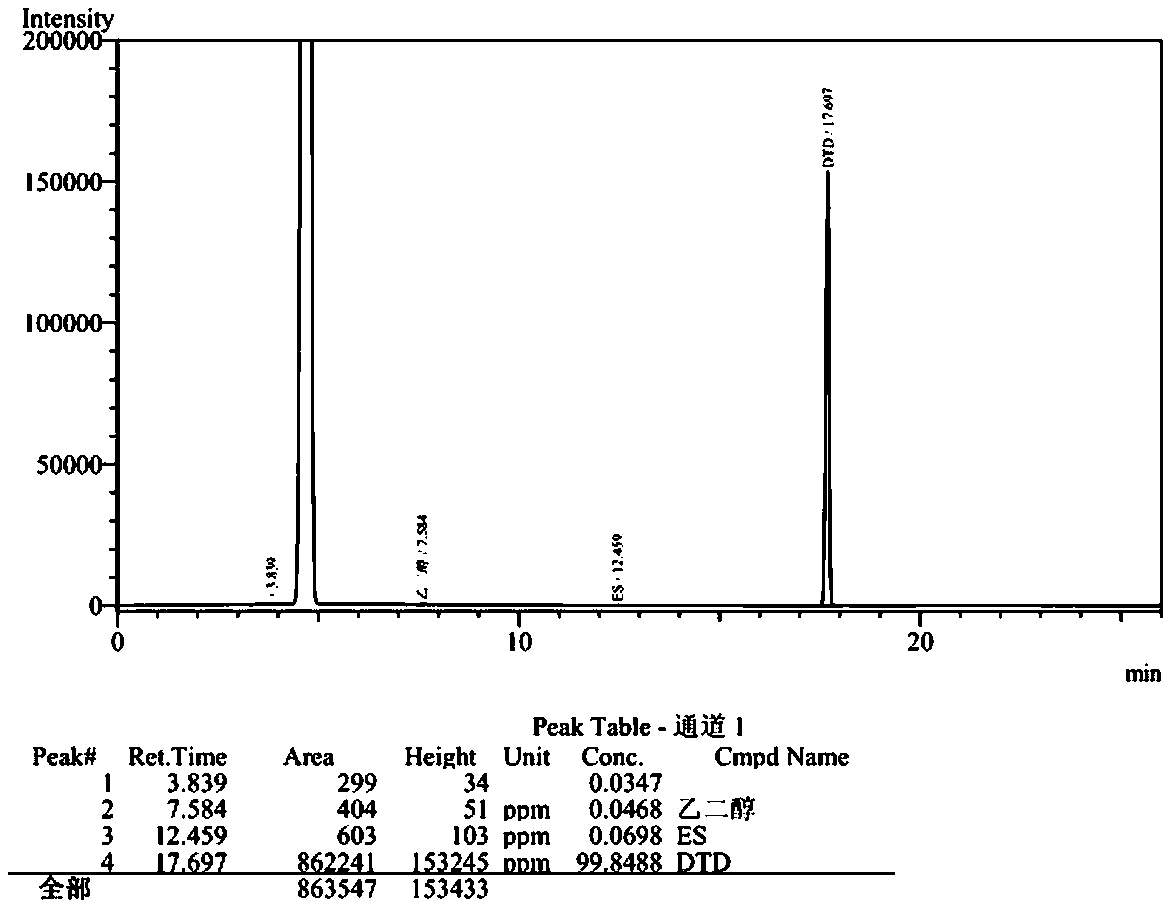

[0054] (1) Substitution reaction: Thionyl chloride and ethylene glycol are used as reaction raw materials for substitution reaction. First, 1300g (10mol) of ethylene glycol is added to the reaction kettle, and then chlorine is added dropwise to the first reaction kettle at room temperature. Sulfoxide 3300g (13mol), the dropwise addition time is 1.5h, and the dropwise addition temperature is controlled at 30°C. After the dropwise addition, keep the temperature at 37°C for 1 hour, then increase the temperature to 50°C, and keep the temperature for 2 hours. Thereby obtain the reaction solution containing vinyl sulfite, wash the reaction solution with deionized water, then let the reaction solution stand, layer and separate vinyl sulfite 2614g (purity is 98.17%), then separate the Vinyl sulfite is added to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com