Application of composite initiating agent in preparation of ion exchange resin

A technology of ion exchange resin and composite initiator, which is applied in the application field of composite initiator in the preparation of ion exchange resin, to achieve the effect of high ball forming rate, good softness of ball and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

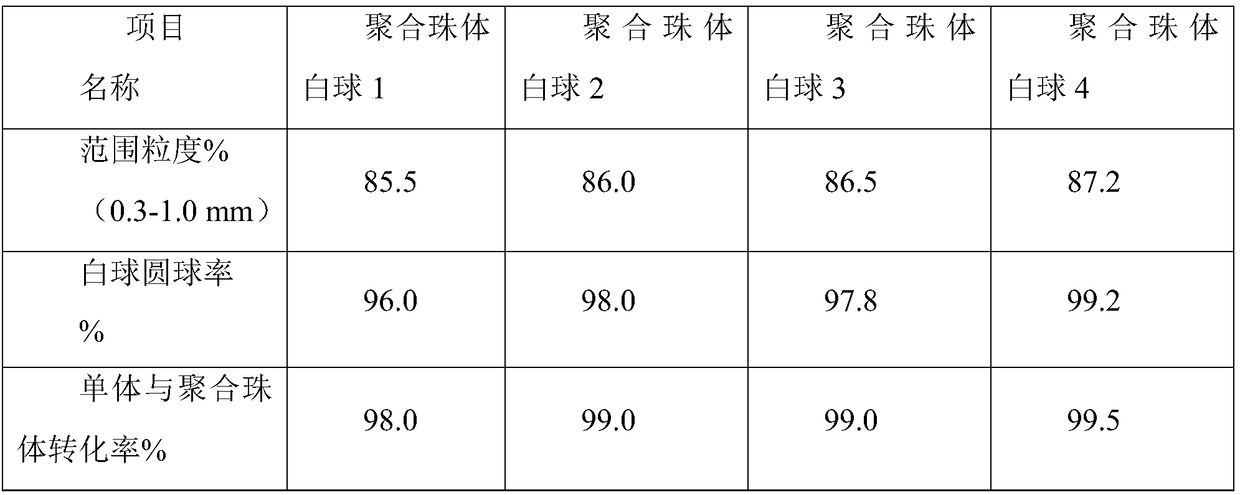

Examples

Embodiment 1

[0026] Macroporous acrylic polymer white balls, the synthesis steps are as follows (the following proportions are calculated based on 1t of polymerized monomer raw materials)

[0027] (1) Prepare the water phase: add 3870Kg of reclaimed NaCl liquid into the reactor, then add 200Kg of industrial salt, wait for it to dissolve completely, measure its specific gravity, adjust its range to 1.13~1.14, add 3.7Kg of hydroxyethyl cellulose, control The water temperature is at 50°C, stir for 30 minutes, and set aside;

[0028] (2) Preparation of oil phase: respectively add 848Kg of acrylonitrile, 62.5Kg of methyl acrylate and 44.7Kg of triacryl isocyanurate into the batching kettle, then add 6.4Kg of benzoyl peroxide to 44.7Kg of di In vinylbenzene, stir and dissolve evenly, then pump into the batching kettle, and finally pump in 148Kg of toluene, stir for 30min, and set aside;

[0029] (3) Put the prepared organic monomer phase into the water phase, the mass ratio of the organic phase...

Embodiment 2

[0031] Macroporous acrylic polymer white balls, the synthesis steps are as follows (the following proportions are calculated based on 1t of polymerized monomer raw materials)

[0032] (1) Prepare the water phase: add 3870Kg of reclaimed NaCl liquid into the reactor, then add 200Kg of industrial salt, wait for it to dissolve completely, measure its specific gravity, adjust its range to 1.13~1.14, add 3.7Kg of hydroxyethyl cellulose, control The water temperature is at 50°C, stir for 30 minutes, and set aside;

[0033] (2) Preparation of oil phase: respectively add 848Kg of acrylonitrile, 62.5Kg of methyl acrylate and 44.7Kg of triacryl isocyanurate into the batching kettle, then add 5.0Kg of azobisisobutylcyanide and 1.4Kg of peroxidized Benzoyl was added to 44.7Kg of divinylbenzene, stirred and dissolved evenly, then pumped into the batching kettle, and finally 148Kg of toluene was pumped in, stirred for 30 minutes, and set aside;

[0034] (3) Put the prepared organic monomer...

Embodiment 3

[0036] Macroporous acrylic polymer white balls, the synthesis steps are as follows (the following proportions are calculated based on 1t of polymerized monomer raw materials)

[0037] (1) Prepare the water phase: add 3870Kg of reclaimed NaCl liquid into the reactor, then add 200Kg of industrial salt, wait for it to dissolve completely, measure its specific gravity, adjust its range to 1.13~1.14, add 3.7Kg of hydroxyethyl cellulose, control The water temperature is at 50°C, stir for 30 minutes, and set aside;

[0038] (2) Prepare the oil phase: add 848Kg of acrylonitrile, 62.5Kg of methyl acrylate and 44.7Kg of triacryl isocyanurate into the batching kettle, then add 1.4Kg of azobisisobutylcyanide and 5.0Kg of peroxidized Benzoyl was added to 44.7Kg of divinylbenzene, stirred and dissolved evenly, then pumped into the batching kettle, and finally 148Kg of toluene was pumped in, stirred for 30 minutes, and set aside;

[0039] (3) Put the prepared organic monomer phase into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com