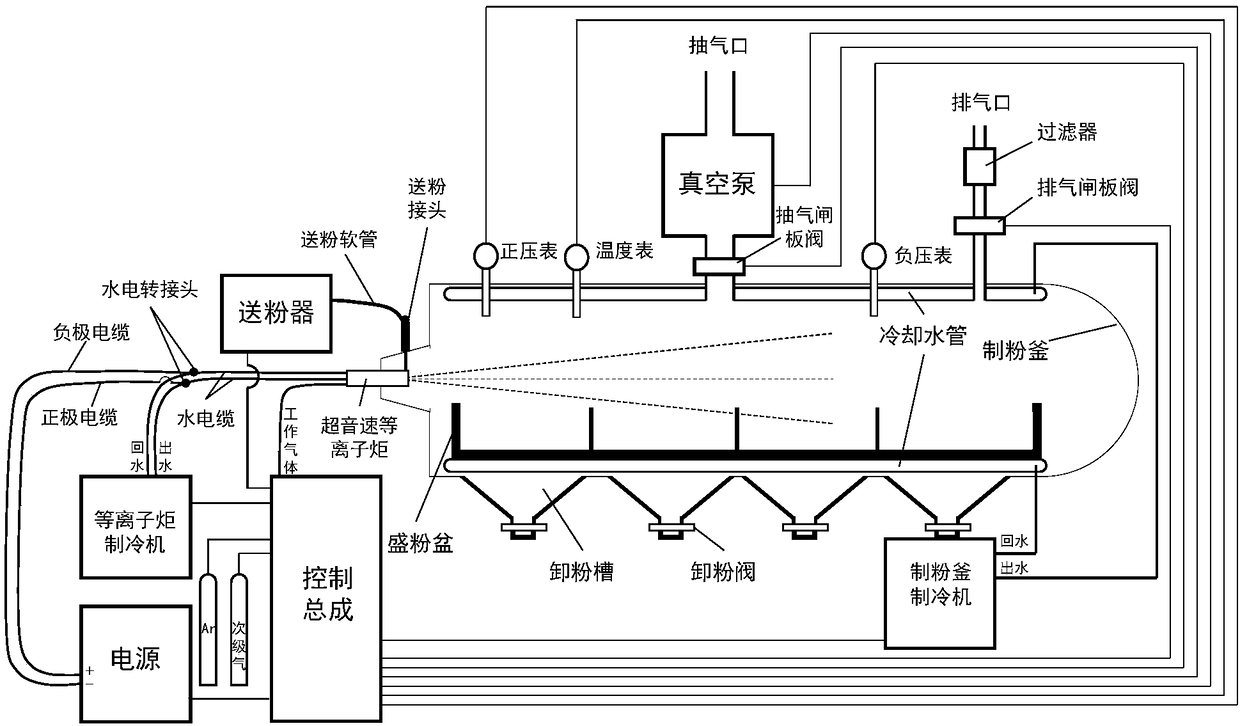

Device and method for spheroidizing powder by utilizing high-energy high-speed plasma flame flow

A plasma and plasma torch technology, which is applied in the field of spherical powder preparation, can solve the problems of many satellites, hollow balls, and poor sphericity, and achieve the effects of fewer satellites, high solidity rate, and high powder-making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

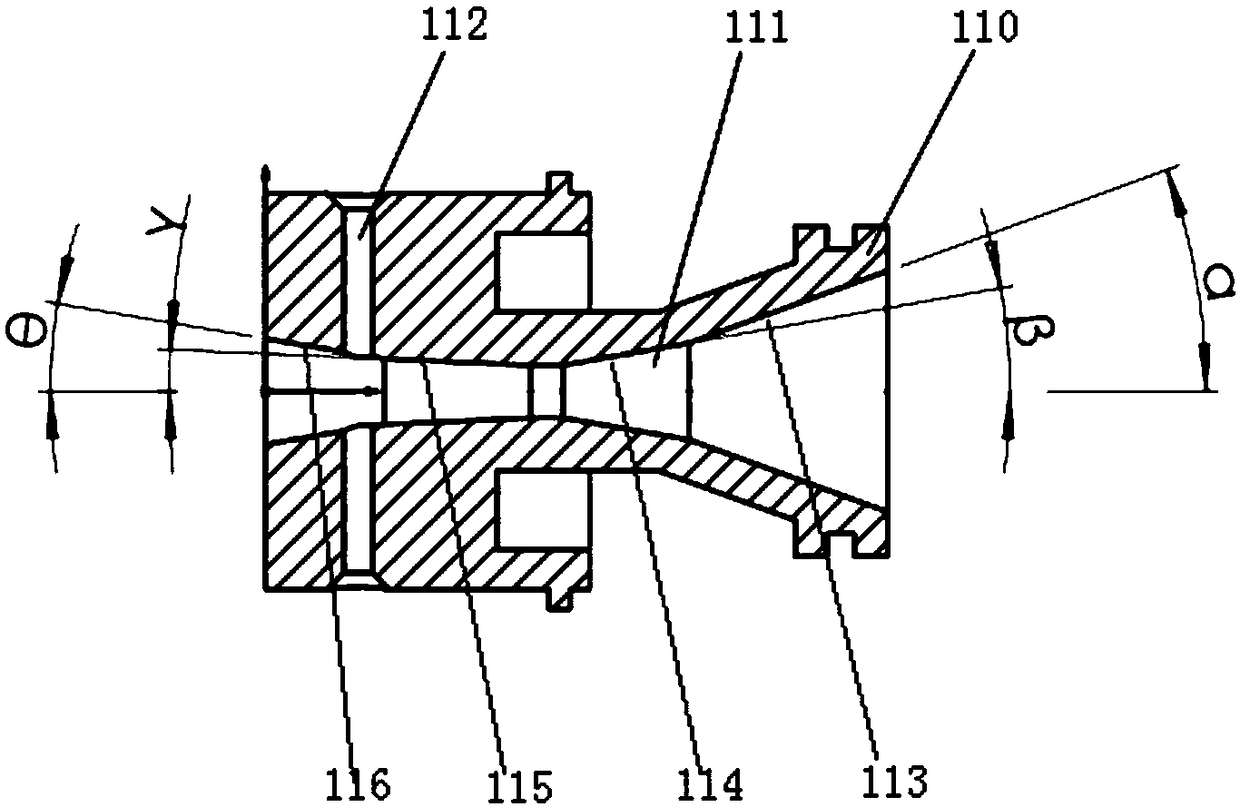

Embodiment 1

[0082] The plasma torch adopts high-energy supersonic plasma torch (supersonic plasma spray gun), and the powder raw material adopts the irregular shape titanium powder prepared by hydrogenation method, and adopts the method of internal powder feeding (nozzle) to feed the powder. The main gas of the inert working gas is argon, and the auxiliary gas is For helium, the specific working parameters are as follows:

[0083]Particle size of powder raw material: 38~58μm,

[0084] Argon flow: 6m 3 / h,

[0085] Helium flow: 2m 3 / h,

[0086] Current: 800A,

[0087] Working voltage: 125V,

[0088] The minimum negative pressure in the powder making kettle: 10mba,

[0089] The maximum positive pressure of the powder making kettle during work: 0.15MPa;

[0090] Control the feeding amount of powder raw material as:

[0091]

[0092] The titanium spherical powder obtained in Example 1 has a proportion of more than 50%; the spherical powder is basically solid, and there are few sat...

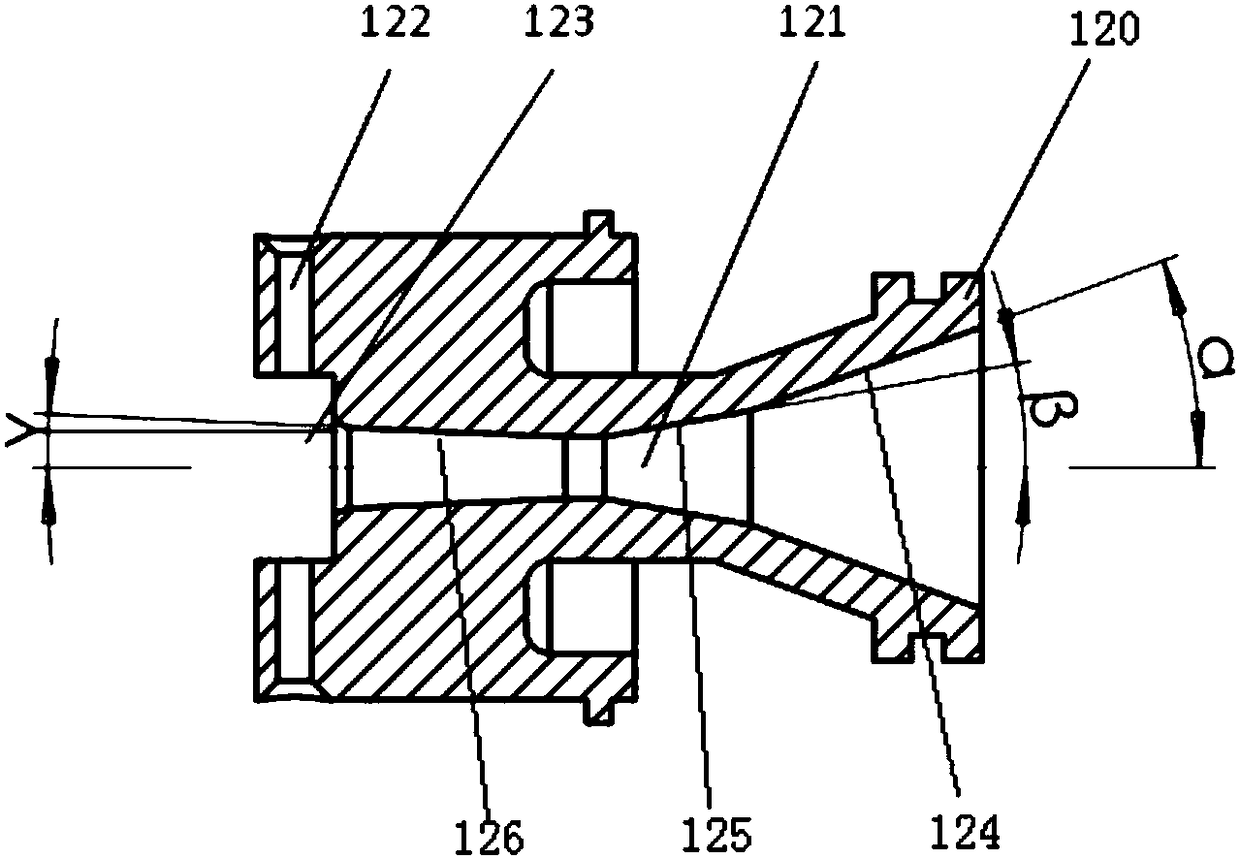

Embodiment 2

[0094] The plasma torch adopts high-energy supersonic plasma torch (spray gun), and the powder raw material adopts irregular shape titanium powder prepared by hydrogenation method, and adopts the method of external powder feeding (nozzle) to feed the powder, the main gas of the inert working gas is argon, and the auxiliary gas is helium , the specific working parameters are as follows:

[0095] Particle size of powder raw material: 38~58μm,

[0096] Argon flow: 5m 3 / h,

[0097] Helium flow: 2m 3 / h,

[0098] Current: 800A,

[0099] Working voltage: 120V,

[0100] The minimum negative pressure in the powder making kettle: 10mba,

[0101] The maximum positive pressure of the powder making kettle during work: 0.15MPa;

[0102] Control the feeding amount of powder raw material as:

[0103]

[0104] The titanium spherical powder obtained in Example 2 has a proportion of more than 40%; the spherical powder is basically solid, and there are few satellites; the milling eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com