Manufacturing method of luminous pet tennis ball

A manufacturing method and tennis ball technology, applied in the field of pet toys, can solve the problems of poor fluorescence intensity, low brightness, short luminous life, etc., and achieve the effects of low cost, improved luminous intensity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

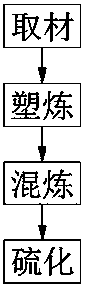

[0019] The manufacturing method of the luminous pet tennis ball comprises the following steps:

[0020] S1: Materials: natural rubber: 55 parts, calcium carbonate: 16 parts, rubber accelerator: 2 parts, rubber oil: 16 parts; dyeing pigment: 0.01 parts, luminescent raw materials: 14 parts, rare earth complex: 1 part and vulcanization Agent: 0.8 part, the vulcanizing agent is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, and the rubber accelerator is N-cyclohexyl-2-benzothiazole Sulfenamide or N,N-dicyclohexyl-2-benzothiazole sulfenamide;

[0021] S2: Masticating: add natural rubber into the plasticating machine for plasticating to obtain plasticized rubber, and park it for 26 hours. The roller temperature of the plasticating machine is 65 degrees Celsius, and the roller distance is 0.8 mm;

[0022] S3: Mixing: put the plasticized rubber obtained in step S2 in an open mixer, add calcium carbonate and rubber oil, mix for 22 minutes, then add rubber accelerator, dyeing pigment, l...

Embodiment 2

[0025] The manufacturing method of the luminous pet tennis ball comprises the following steps:

[0026] S1: Materials: natural rubber: 60 parts, calcium carbonate: 12 parts, rubber accelerator: 4 parts, rubber oil: 8 parts; dyeing pigment: 0.04 parts, luminous raw materials: 8 parts, rare earth complex: 2 parts and vulcanization Agent: 0.5 part, the vulcanizing agent is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, and the rubber accelerator is N-cyclohexyl-2-benzothiazole Sulfenamide or N,N-dicyclohexyl-2-benzothiazole sulfenamide;

[0027] S2: Masticating: add natural rubber into the plasticating machine for plasticating to obtain plasticized rubber, and park it for 22 hours. The roller temperature of the plasticating machine is 55 degrees Celsius, and the roller distance is 0.4 mm;

[0028] S3: Mixing: put the plasticized rubber obtained in step S2 in an open mixer, add calcium carbonate and rubber oil, mix for 18 minutes, then add rubber accelerator, dyeing pigment, lumin...

Embodiment 3

[0031] The manufacturing method of the luminous pet tennis ball comprises the following steps:

[0032] S1: Materials: natural rubber: 58 parts, calcium carbonate: 14 parts, rubber accelerator: 3 parts, rubber oil: 12 parts; dyeing pigment: 0.02 parts, luminescent raw materials: 11 parts, rare earth complex: 2 parts and vulcanization Agent: 0.6 part, the vulcanizing agent is 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, and the rubber accelerator is N-cyclohexyl-2-benzothiazole Sulfenamide or N,N-dicyclohexyl-2-benzothiazole sulfenamide;

[0033] S2: Masticating: add natural rubber into the plasticating machine for plasticating to obtain plasticized rubber, and park it for 24 hours. The roller temperature of the plasticating machine is 60 degrees Celsius, and the roller distance is 0.6 mm;

[0034] S3: Mixing: Put the plasticized rubber obtained in step S2 in an open mixer, add calcium carbonate and rubber oil, mix for 20 minutes, then add rubber accelerator, dyeing pigment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com