Anticorrosion coating of stereoscopic-structure graphene-reinforced epoxy resin

A technology of anti-corrosion coatings and epoxy resins, applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor weather resistance, short service life, low barrier properties, etc., to improve mechanical properties, prolong protection time, The effect of overcoming poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

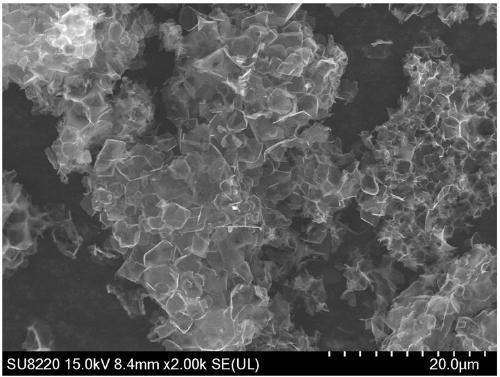

Image

Examples

Embodiment 1

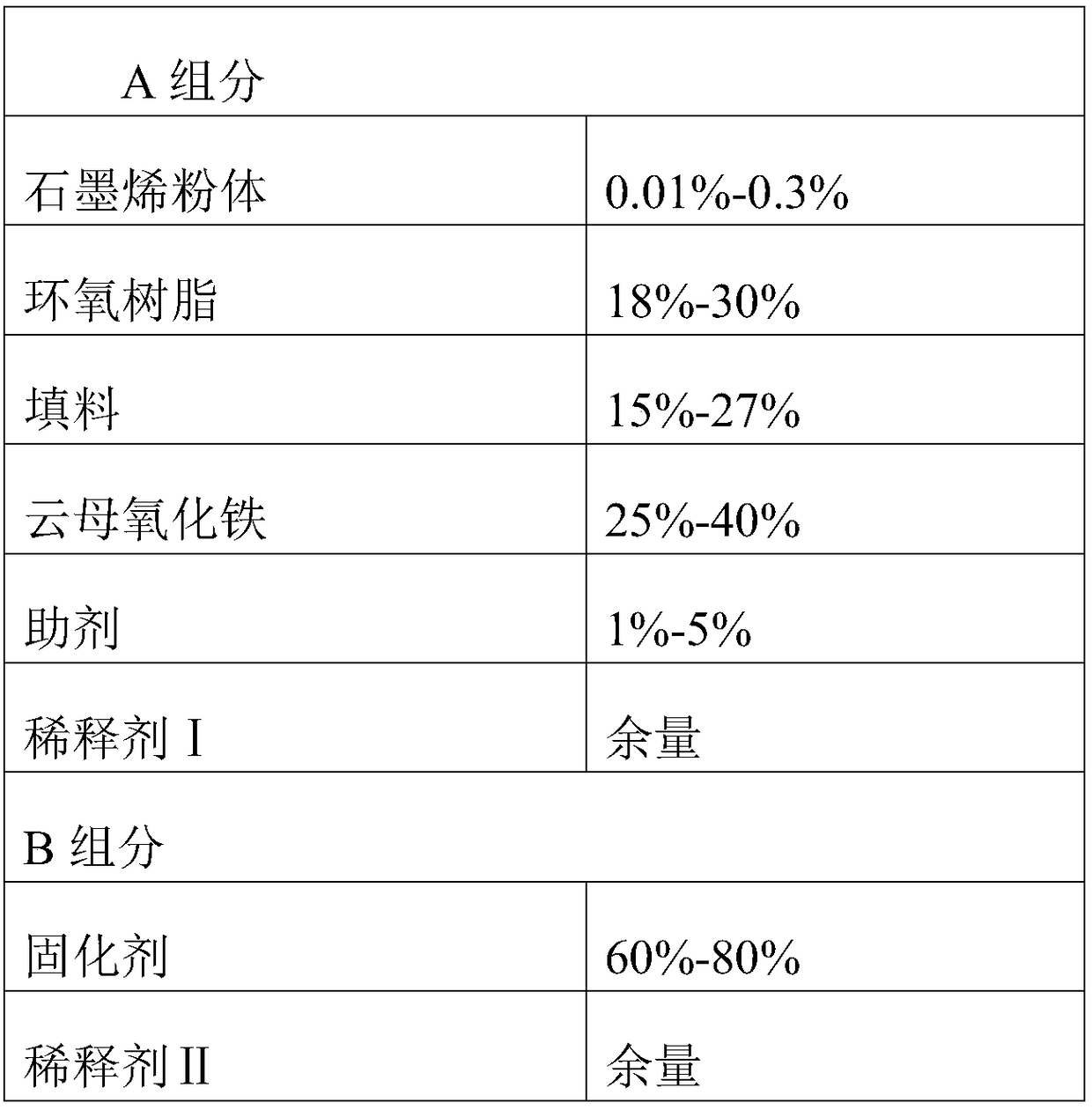

[0032] According to the mass ratio of xylene: n-butanol: cyclohexanone = 1:0.5:0.5, weigh xylene, n-butanol and cyclohexanone, then mix and stir evenly to obtain diluent I, and set aside; according to the mass ratio of xylene: n-butanol: cyclohexanone = 1:0.5:0.5, weigh xylene, n-butanol and cyclohexanone, and then mix and stir evenly to obtain diluent II for later use.

[0033]

[0034] A kind of preparation method of the anticorrosion coating of three-dimensional structure graphene reinforced epoxy resin, operation steps are as follows:

[0035] (1) Weigh each component according to the mass percentage in the above table, then mix and ball-mill disperse E20 epoxy resin, diluent I and graphene powder that weighs 50% of the total mass of diluent I obtained, to obtain a graphene ring Oxygen resin liquid;

[0036] (2) Weigh the filler (titanium dioxide, talcum powder, calcium carbonate and carbon black), additives (coupling agent KH-550, anti-sedimentation agent bentonite an...

Embodiment 2

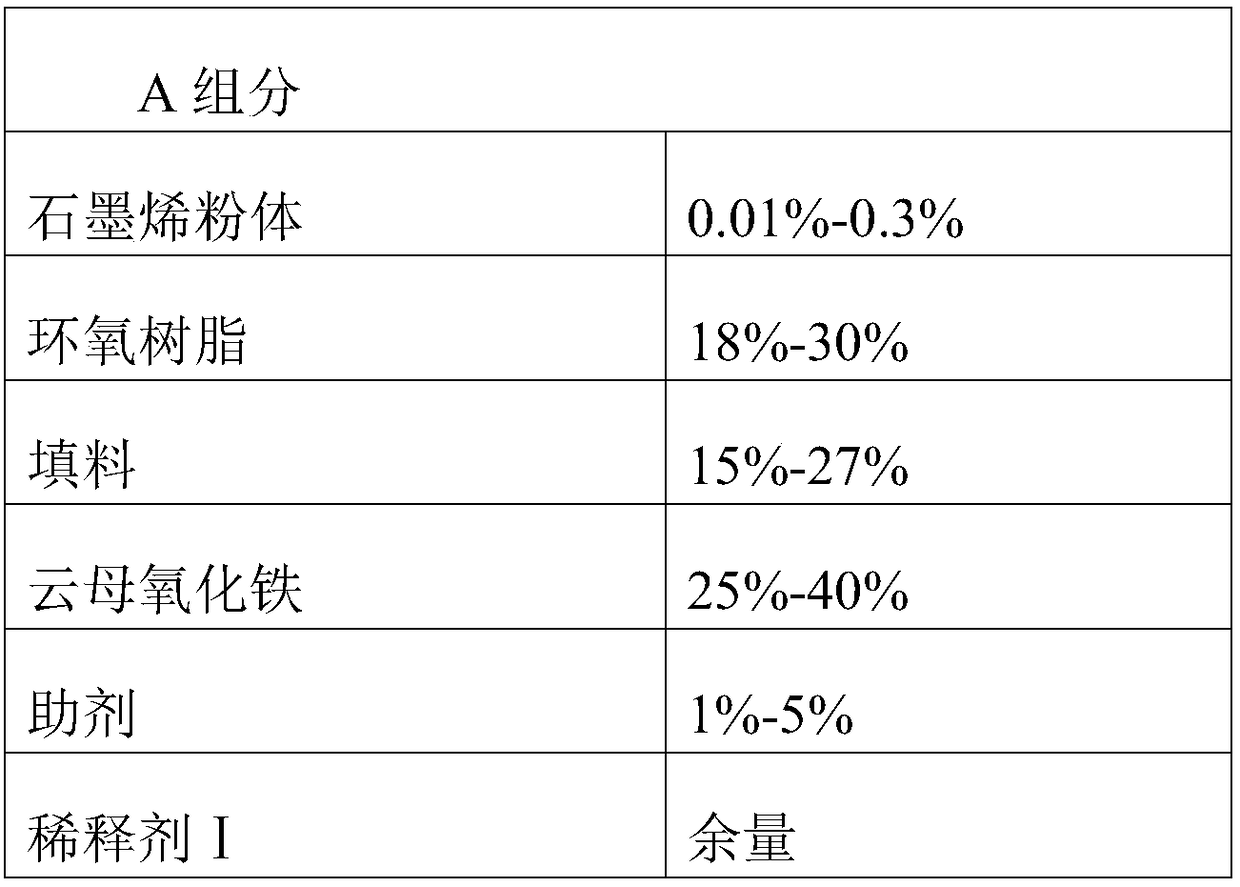

[0041] According to the mass ratio of xylene: n-butanol: cyclohexanone = 1:0.3:0.3, weigh xylene, n-butanol and cyclohexanone, then mix and stir evenly to obtain diluent I, and set aside; according to the mass ratio of xylene: n-butanol: cyclohexanone = 1:0.3:0.3, weigh xylene, n-butanol and cyclohexanone, and then mix and stir evenly to obtain diluent II for later use.

[0042]

[0043]

[0044] A kind of preparation method of the anticorrosion coating of three-dimensional structure graphene reinforced epoxy resin, operation steps are as follows:

[0045] (1) Weigh each component according to the mass percentage in the above table, then E20 epoxy resin, diluent I and graphene powder that weighs 50% of the total mass of diluent I obtained are mixed and sand-milled to disperse graphene Epoxy resin liquid;

[0046] (2) Weigh the filler (titanium dioxide, talcum powder, calcium carbonate and carbon black), additives (coupling agent KH-550, anti-sedimentation agent bentonit...

Embodiment 3

[0051] According to the mass ratio of xylene: n-butanol: cyclohexanone = 1:0.6:0.6, weigh xylene, n-butanol and cyclohexanone, then mix and stir evenly to obtain diluent I, and set aside; according to the mass ratio of xylene: n-butanol: cyclohexanone = 1:0.6:0.6, weigh xylene, n-butanol and cyclohexanone, and then mix and stir evenly to obtain diluent II for later use.

[0052]

[0053] A kind of preparation method of the anticorrosion coating of three-dimensional structure graphene reinforced epoxy resin, operation steps are as follows:

[0054] (1) Weigh each component according to the mass percentage in the above table, then mix and ball-mill disperse E20 epoxy resin, diluent I and graphene powder that weighs 50% of the total mass of diluent I obtained, to obtain a graphene ring Oxygen resin liquid;

[0055] (2) Weigh the filler (titanium dioxide, talcum powder, calcium carbonate and carbon black), additives (coupling agent KH-792, anti-sedimentation agent bentonite an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com