Polyurea polyaspartic acid ester paint raw material composition, paint from same and preparation and application methods thereof

A technology of aspartate and raw material composition, applied in the direction of polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of unsuitability for small-area construction, short polyurea gel time, unstable color, etc. , to achieve the effect of good tolerance, color stability, and wide adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

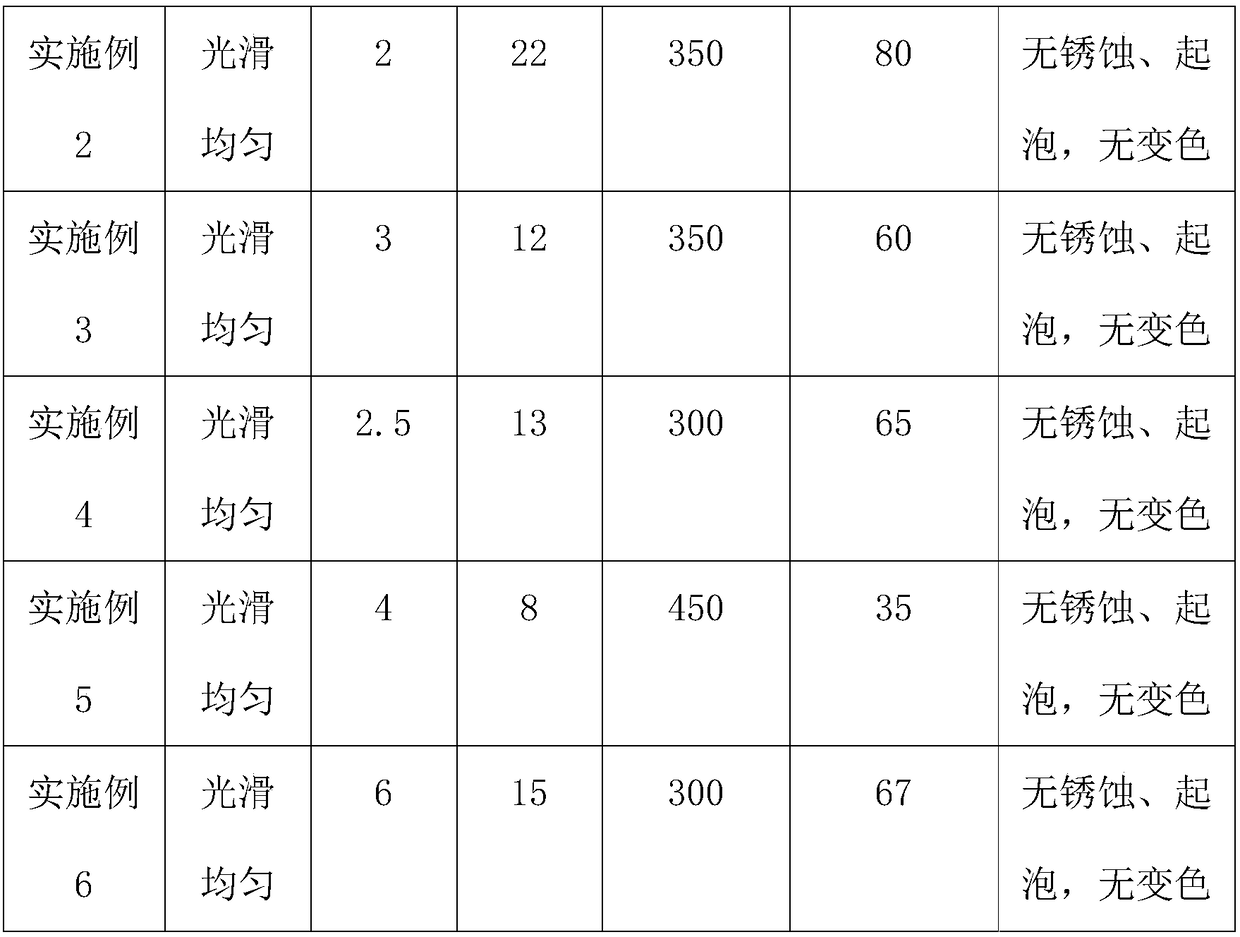

Examples

preparation example Construction

[0040] The raw materials for the preparation of the prepolymer include: 60%-80% of polymer polyols, 19.5%-39.9% of aliphatic isocyanate, and 0.1%-0.5% of catalysts, and the percentages are the weight of each component. The mass percentage of the raw materials for the preparation of the prepolymer, the sum of the percentages of each component is 100%;

[0041] The polymer polyol is selected from polyether polyol (such as DL-2000, DL-1000), polyester polyol (such as PCD-N963, PCD-N964, F1700, F1190, PCL) and polytetrahydrofuran polyol (such as One or more of PTMG-2000), the polymer polyol has a functionality of 2 and a number average molecular weight of 1000 to 5000;

[0042] Described isocyanate is selected from HDI, H 12 One or more of MDI, IPDI, HDI trimer, IPDI trimer, preferably HDI and IPDI;

[0043] The catalyst is an organotin catalyst, preferably T9 or T12;

[0044] The raw materials for the preparation of the polyamine include: 37%-80% polyaspartic acid ester resin,...

Embodiment 1

[0066] (1) Preparation of NCO-terminated prepolymer

[0067] In terms of mass percentage, add 80% PCD N-963 and heat up to 105°C, dehydrate under negative pressure -0.095MPa for 1h, then cool down to 60°C, add 19.5% HDI and 0.5% T12, stir and disperse, then heat up to 75°C, Fully react for 2 hours and cool down to 55°C, filter and discharge to obtain a prepolymer.

[0068] (2) Preparation of polyamine

[0069] In terms of mass percentage, first add 50% of Desmophen NH 1420, 27% of titanium dioxide, 5% of anti-corrosion pigments, 5% of molecular sieves, 1.5% of BYK-110, 1.2% of BYK-066N and 0.3% of GARAMATE- In 1958, use a high-speed disperser to quickly disperse for 45 minutes, then add 5% butyl acetate and 5% propylene glycol methyl ether acetate, continue to disperse at a high speed for 40 minutes, and discharge after standing for 5 minutes to obtain polyamine.

[0070] (3) Preparation of polyurea-type polyaspartate paint coating

[0071] Mix the prepolymer in (1) and the...

Embodiment 2

[0073] (1) Preparation of NCO-terminated prepolymer

[0074] In terms of mass percentage, add 70% of F1700 and heat up to 105°C, negative pressure -0.095MPa for dehydration for 1h, then cool down to 60°C, add 29.9% of IPDI and 0.1% of T12, stir and disperse, then heat up to 75°C, fully react for 3h Cool down to 55°C, filter and discharge to obtain prepolymer.

[0075] (2) Preparation of polyamine

[0076] In terms of mass percentage, first add 40% of Desmophen NH 1420, 30% of titanium dioxide, 5% of anti-corrosion pigments, 5% of molecular sieves, 3.2% of BYK-110, 1.5% of BYK-066N and 0.3% of GARAMATE- In 1958, use a high-speed disperser to quickly disperse for 45 minutes, then add 5% butyl acetate and 10% propylene glycol methyl ether acetate, continue to disperse at a high speed for 40 minutes, and discharge after standing for 5 minutes to obtain polyamine.

[0077] (3) Preparation of polyurea-type polyaspartate paint coating

[0078] Mix the prepolymer in (1) and the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com