Production method of yeast soy sauce flavor type high ester seasoning spirit

A technology of Daqu Maotai flavor and production method, which is applied in the preparation of alcoholic beverages and other directions, can solve problems such as hidden dangers of food safety and low total ester content, and achieve the effects of improving taste, promoting absorption, improving total ester content and alcohol yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

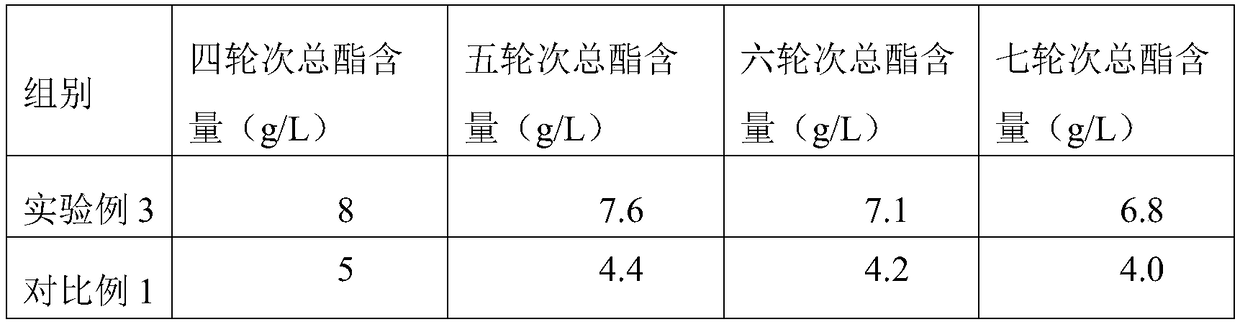

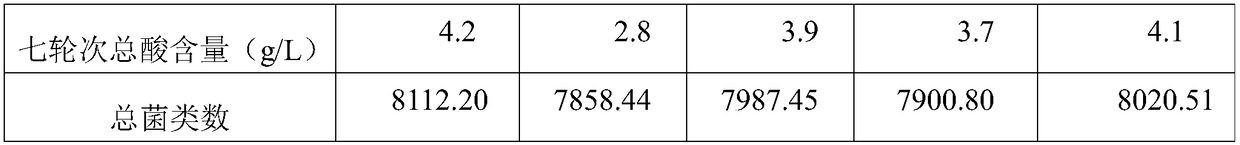

Examples

Embodiment 1

[0024] Sand steamed grain: Crush the glutinous sorghum until the crushing degree is 20%, then add hot water at 98°C to moisten the grain for 5 hours, then divide the glutinous sorghum and distiller's grains into 10 equal parts and pour them into the wine steamer, and cover the steamer after steaming , steam pressure 0.1~0.12MPa, steamed grain for 65min, the steamed glutinous sorghum was taken out of the retort to obtain sand steamed grain (the obtained cooked grain was tested, the moisture of cooked grain was 44%, and the gelatinization rate was 95%), Wherein, the amount of hot water is 52% of the total mass of waxy sorghum;

[0025] Mixing koji with sand: Pour the steamed rice with sand on the ground and spread it out, add 1% of the total mass of glutinous sorghum in 95-100°C water for mixing, then use a blower to cool down to 40°C, add 1% of the total mass of glutinous sorghum in wine tail, Then add glutinous sorghum koji powder with 8% of the total mass and carry out two sa...

Embodiment 2

[0039] Sand steamed grain: Crush the glutinous sorghum until the crushing degree is 20%, then add hot water at 98°C to moisten the grain for 5 hours, then divide the glutinous sorghum and distiller's grains into 10 equal parts and pour them into the wine steamer, and cover the steamer after steaming , steam pressure 0.1~0.12MPa, steamed grain for 65min, the steamed glutinous sorghum was taken out of the retort to obtain sand steamed grain (the obtained cooked grain was tested, the moisture of cooked grain was 44%, and the gelatinization rate was 95%), Wherein, the amount of hot water is 52% of the total mass of waxy sorghum;

[0040]Mixing koji with sand: Pour the steamed rice with sand on the ground and spread it out, add 1.5% of the total mass of glutinous sorghum in water at 95-100°C and mix, then use a blower to cool down to 44°C, add 1.5% of the total mass of glutinous sorghum in wine tail, Then add glutinous sorghum koji powder with a total mass of 8.5% and carry out two...

Embodiment 3

[0054] Sand steamed grain: Crush the glutinous sorghum until the crushing degree is 20%, then add hot water at 98°C to moisten the grain for 5 hours, then divide the glutinous sorghum and distiller's grains into 10 equal parts and pour them into the wine steamer, and cover the steamer after steaming , steam pressure 0.1~0.12MPa, steamed grain for 65min, the steamed glutinous sorghum was taken out of the retort to obtain sand steamed grain (the obtained cooked grain was tested, the moisture of cooked grain was 44%, and the gelatinization rate was 95%), Wherein, the amount of hot water is 52% of the total mass of waxy sorghum;

[0055] Mixing koji with sand: Pour the steamed rice with sand on the ground and spread it out, add 2% of the total mass of glutinous sorghum in water at 95-100°C and mix, then use a blower to cool down to 45°C, add 2% of the total mass of glutinous sorghum in wine tail, Add koji powder with 9% of the total mass of glutinous sorghum and carry out two sacc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com