Plant-sourced compound functional herbal cotton fibre and preparation method thereof

A composite function, cotton fiber technology, applied in the direction of plant fiber, fiber treatment, wear-resistant fiber, etc., can solve the problems of cotton fabric damage, mold resistance, poor wear resistance, etc., to protect children's health and good mildew resistance , good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

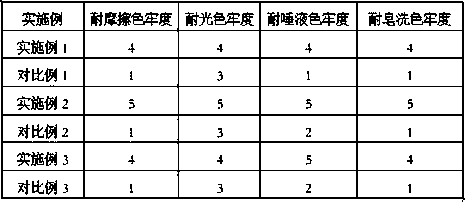

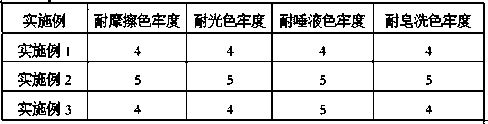

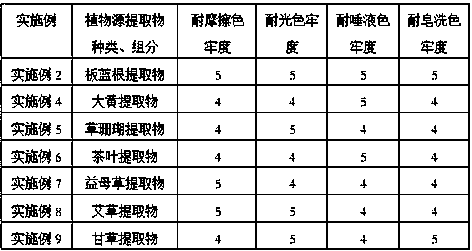

Examples

Embodiment 1

[0063] Embodiment 1 A kind of preparation method of herbaceous cotton fiber of composite function of plant source, specifically comprises the following steps:

[0064] 1. Pretreatment steps of cotton fiber:

[0065] 1. Put the cotton fiber after carding and removing impurities into the dyeing tank, add sodium hydroxide solution and natural active agent to make a bath liquid; the liquid bath ratio is 1:10, then turn on the circulation pump and start circulation, The power is 25 kilowatts, and the speed of the bath liquid ejected from the cage core is 20 m / s; the temperature of the bath liquid is slowly raised to 95 °C at a speed of 2 °C / min, and kept for 60 minutes for later use;

[0066] The concentration of sodium hydroxide solution is 4%; the natural active agent is sorbitan fatty acid ester, and the addition amount is 0.5% of the cotton fiber weight.

[0067] 2. After step 1 heat preservation, lower the temperature of the bath liquid to 20°C and then add hydrogen peroxide;...

Embodiment 2

[0086] Embodiment 2 A kind of preparation method of herbaceous cotton fiber of plant source compound function, specifically comprises the following steps:

[0087] 1. Pretreatment steps of cotton fiber:

[0088] 1. Put the cotton fiber after carding and removing impurities into the dyeing tank, add sodium hydroxide solution and natural active agent to make a bath liquid; the liquid bath ratio is 1:10, then turn on the circulation pump and start circulation, The power is 25 kilowatts, and the speed of the bath liquid ejected from the cage core is 21 m / s; the temperature of the bath liquid is slowly raised to 96 °C at a speed of 2 °C / min, and kept for 70 minutes for later use;

[0089] The concentration of sodium hydroxide solution is 5%; the natural active agent is sorbitan fatty acid ester; the addition amount of sorbitan fatty acid ester is 0.6% of the cotton fiber weight.

[0090] 2. Cool down the temperature of the bath liquid in step 1 to 18°C and then add hydrogen pero...

Embodiment 3

[0108] Embodiment 3 A kind of preparation method of herbaceous cotton fiber of composite function of plant source, specifically comprises the following steps:

[0109] 1. Pretreatment steps of cotton fiber:

[0110] 1. Put the cotton fiber after carding and removing impurities into the dyeing tank, add sodium hydroxide solution and natural active agent to make a bath liquid; the liquid bath ratio is 1:10, then turn on the circulation pump and start circulation, The power is 30 kilowatts, and the speed of the bath liquid ejected from the cage core is 22 m / s; the temperature of the bath liquid is slowly raised to 99 °C at a speed of 3 °C / min, and it is kept for 90 minutes for later use;

[0111] The concentration of sodium hydroxide solution is 6%; the natural active agent is sorbitan fatty acid ester; the addition amount of sorbitan fatty acid ester is 0.8% of the cotton fiber weight.

[0112] 2. Cool down the temperature of the bath liquid after the heat preservation in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com