Spinel structure coated modified lithium cobalt oxide-based material, preparation method and lithium battery

A technology of spinel structure and property of lithium cobalt oxide, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problem that the coating material does not have electrochemical activity, the ionic and electronic conductivities are limited, and the synthesis of materials is limited. performance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

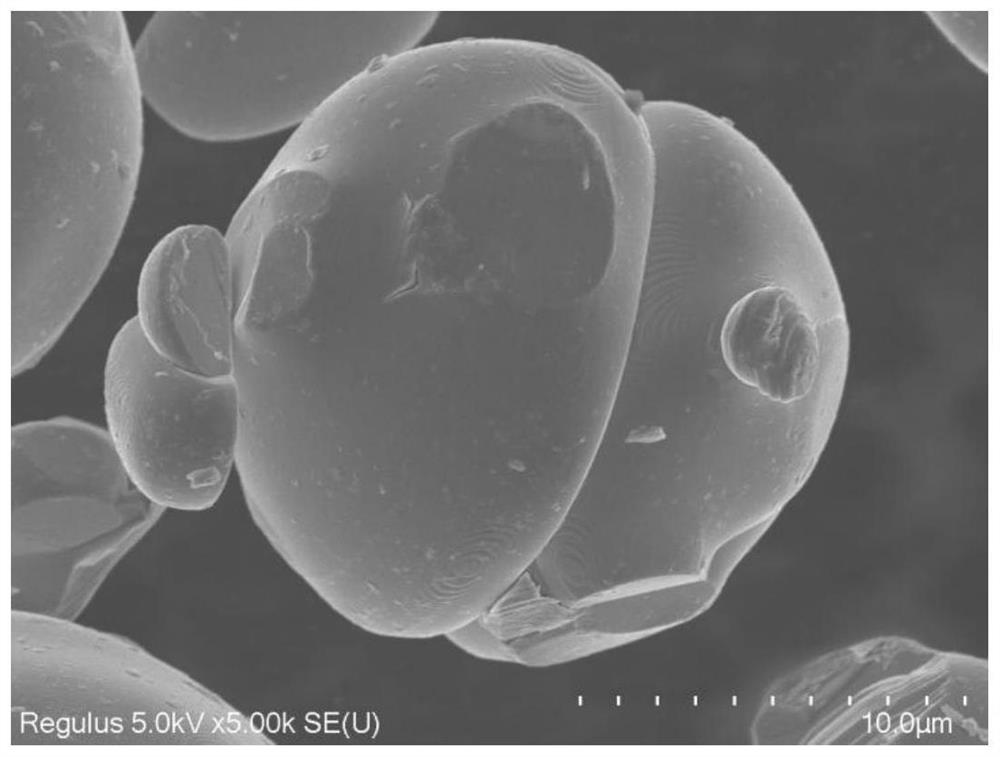

[0068] This example uses a solid-state method to synthesize oxyfluoride spinel coated on LiCoO 2 A modified lithium cobaltate-based material coated with a spinel structure was prepared on the particle.

[0069] (1) Take 0.2288g Li 2 CO 3 , 0.0918g LiF, 1.2524g MnO 2 , and 0.4388g LiCoO 2 Mixed by ball milling in a ball mill jar, ball milled at 300rpm for 2 hours, the ball milled powder was pressed into tablets, then transferred to a box furnace, and sintered at 700°C for 4 hours to obtain Li 1.18 co 0.38 mn 1.22 o 3.7 f 0.3 Oxyfluoride with spinel structure.

[0070] (2) Dissolve 0.01g of polyvinylpyrrolidone (PVP, K40, Mw=40000) in 60ml of deionized water, keep stirring at 50°C for 30min, and then add 0.01g of spinel-structured fluorine oxide synthesized in step (1) material, the temperature was kept at 50°C, stirred for 30min; then 1g LiCoO was added 2 , raise the temperature to 95°C, and stir until the solvent evaporates completely. The remaining solid powder aft...

Embodiment 2

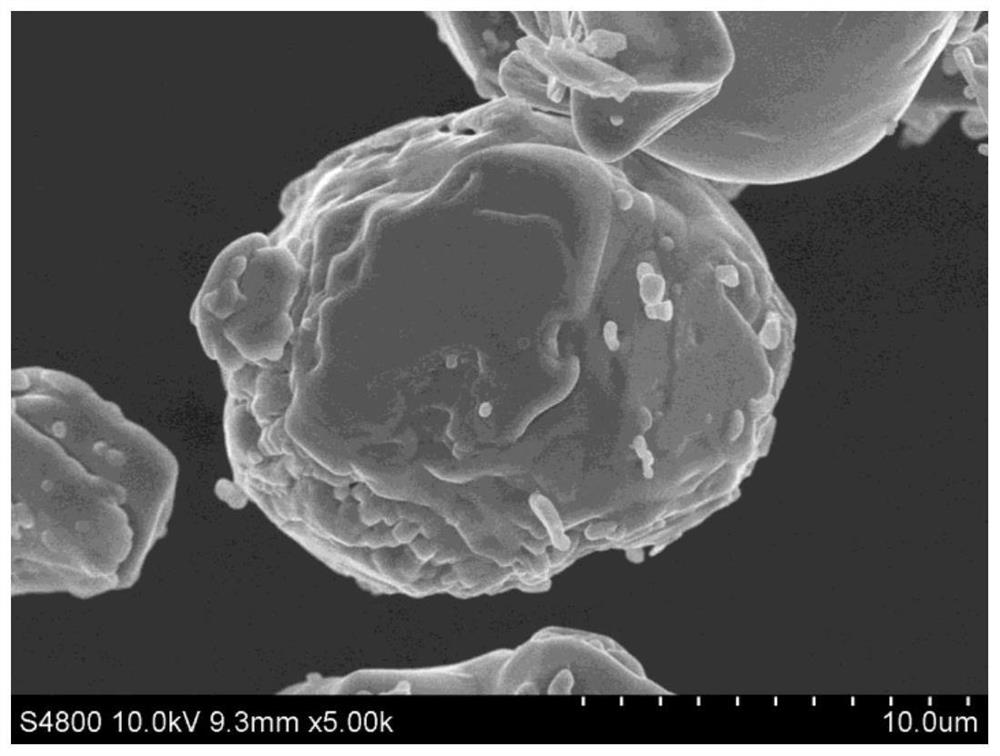

[0073] This example uses the sol-gel method to synthesize oxyfluoride spinel coated on LiCoO 2 A modified lithium cobaltate-based material coated with a spinel structure was prepared on the particle.

[0074] (1) Dissolve 0.7593g lithium acetate dihydrate, 1.8821g manganese acetate tetrahydrate, 0.6033g cobalt acetate tetrahydrate, 48uL trifluoroacetic acid into 100mL deionized water, add 2.925g PVP at the same time, keep the temperature at 50°C, and stir for 30min , and then the temperature was raised to 95°C until all the water formed was evaporated to dryness and a jelly-like substance was formed.

[0075] (2) Put the jelly obtained in (1) into a box furnace, calcined at 500°C for 6 hours, take it out and grind it into powder, and then calcined at 700°C for 6 hours to obtain the composition Li 1.26 co 0.41 mn 1.3 o 3.682 f 0.32 spinel oxyfluoride nanoparticles.

[0076] (3) As in Example 1, dissolve 0.01g of polyvinylpyrrolidone (PVP, K40, Mw=40000) in 60ml of deioniz...

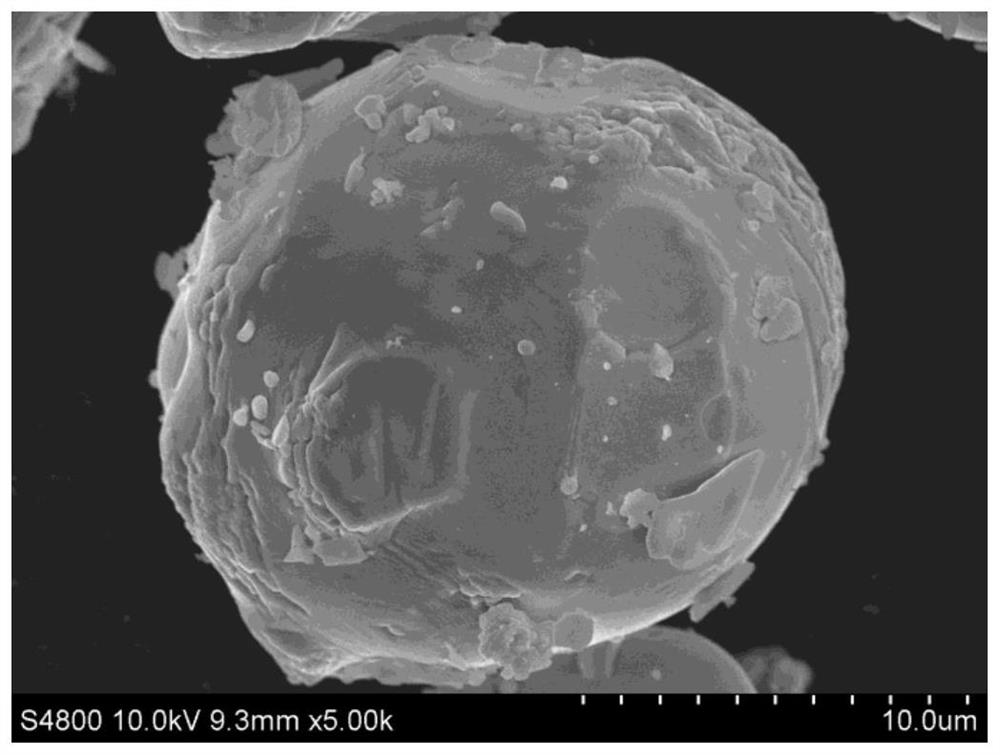

Embodiment 3

[0079] In this example, the sol-gel route of citric acid and ethylene glycol is used, and lithium cobalt oxide is added while synthesizing the spinel coating material, so as to obtain dense lithium cobalt oxide coated with spinel oxyfluoride in one step.

[0080] (1) Add 0.0304g lithium acetate dihydrate, 0.0753g manganese acetate tetrahydrate, 0.0241g cobalt acetate tetrahydrate, 3uL trifluoroacetic acid, 0.1180g citric acid monohydrate and 35uL ethylene glycol into 50mL deionized water, and keep the temperature Stir at 70°C for 30 min, then add LiCoO 2 Powder, stirred for 2 hours; heated to 120°C, evaporated to dryness to obtain lithium cobaltate particles coated with gel-like substance.

[0081] (2) The solid obtained in (1) was pre-calcined at 400°C for 6 hours, taken out, fully ground, and then calcined at 900°C for 6 hours to obtain 2wt% spinel oxyfluoride-coated lithium cobaltate .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com