Self-alignment process for improving performance of safe working area of gate-controlled power device

A technology of safe working area and self-alignment process, which is applied in the field of gate-controlled power devices, can solve the problems of high doping concentration difficulty in heavily doped P-type regions, alignment deviation of lithography process, and large spacing, etc., to achieve The device performance consistency is improved, the process is simple, and the effect of improving the performance of the safe working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

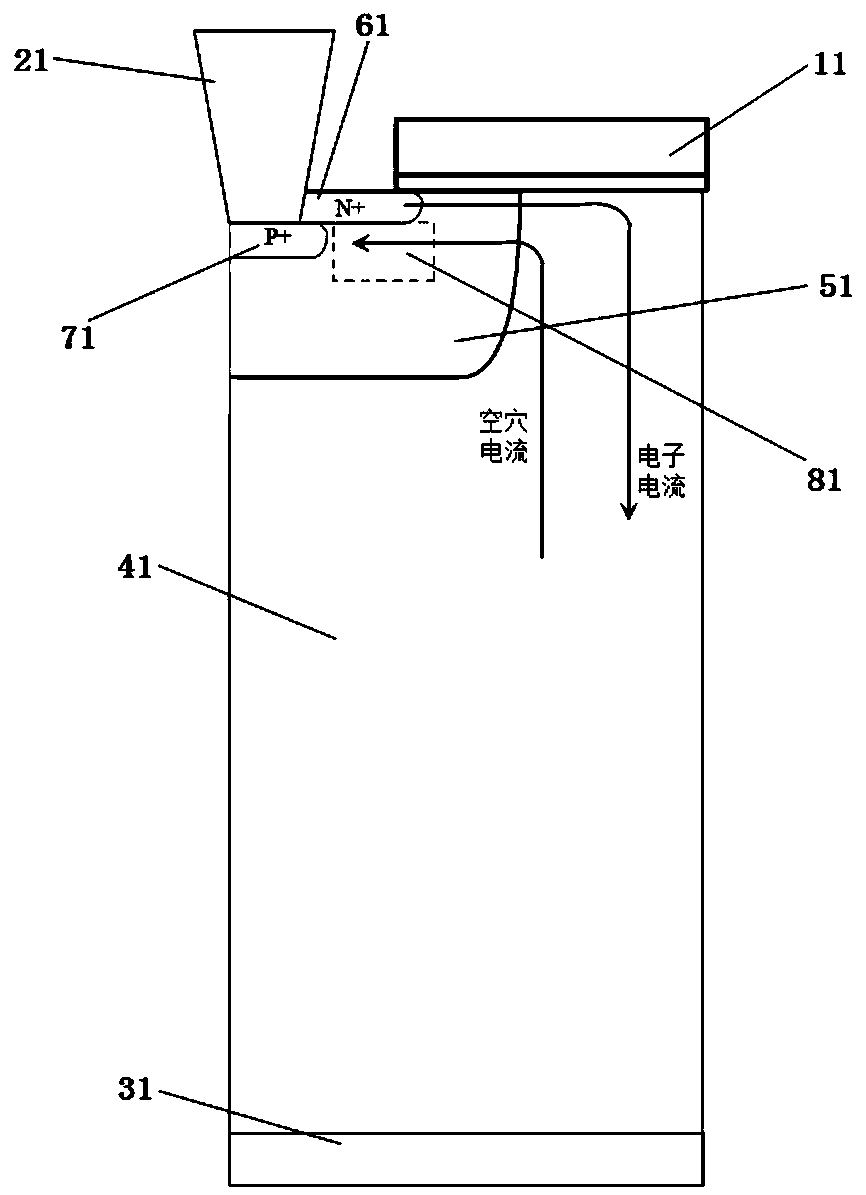

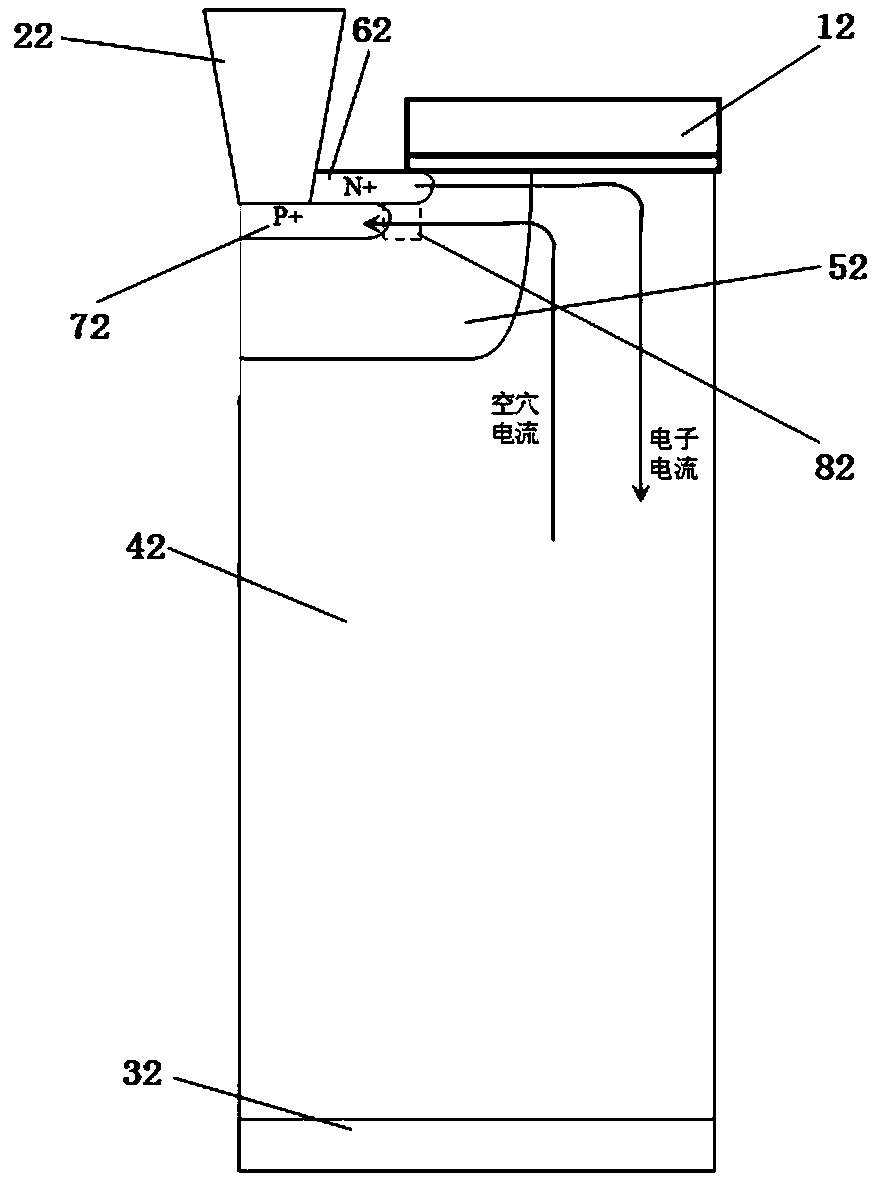

[0021] The structure of the gate-controlled power device in the prior art is as follows figure 1 As shown, it includes an N-type substrate 41 , a gate 11 , an emitter contact hole 21 , a collector 31 , a P-type well 51 , a heavily doped N-type region 61 and a heavily doped P-type region 71 . The region between the heavily doped P-type region 71 and the gate 11 is a region 81 .

[0022] During the processing of gate-controlled power devices in the prior art, hole current flows under the heavily doped N-type region 61 and is absorbed by the emitter. Since the emitter and the heavily doped N-type region 61 are always at zero potential, there will be doping in the P-type region (the P-type region includes the P-type well 51 and the heavily doped P-type region 71) below the heavily doped N-type region 61. As a result, there is a potential difference between the heavily doped N-type region 61 and the P-type region. When the hole current increases, especially when the device is tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com