Preparation and application of ferric fluoride doping nano titanium dioxide

A technology of nano-titanium dioxide and ferric fluoride, which is applied in secondary batteries, electrochemical generators, electrical components, etc., can solve the problems of difficulty in preparation, rising cost, and high-temperature hydrolysis, and achieve excellent cycle performance and actual capacity , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First weigh 0.1gTiO 2 Dissolve completely in 30ml of distilled water as a milky white liquid, then let it stand for 12-16 hours, then add 4mg of cetyltrimethylammonium bromide and 20.2g of Fe(NO 3 ) 3 .9H 2 O was stirred with a glass rod in an ultrasonic wave to dissolve it completely, and it appeared as a brownish-yellow liquid; after stirring for 10 minutes, place it in a polytetrafluoroethylene plastic bottle, add 12ml of 40% hydrofluoric acid to become colorless, and stir for 24 hours Turn into a pink liquid; then add isopropanol dropwise until the solution turns into a colorless liquid, stir for 30 minutes, then heat up to 80°C, heat and stir for 24 hours to evaporate excess hydrofluoric acid and water, and obtain light yellow FeF 3 (H 2 0) 4.5 / TiO 2 ; then vacuum-dried at 80°C for 24h in a vacuum oven, and then vacuum-dried at 120°C for 24h in a vacuum oven to obtain light green FeF 3 (H 2 0) X / TiO 2 .

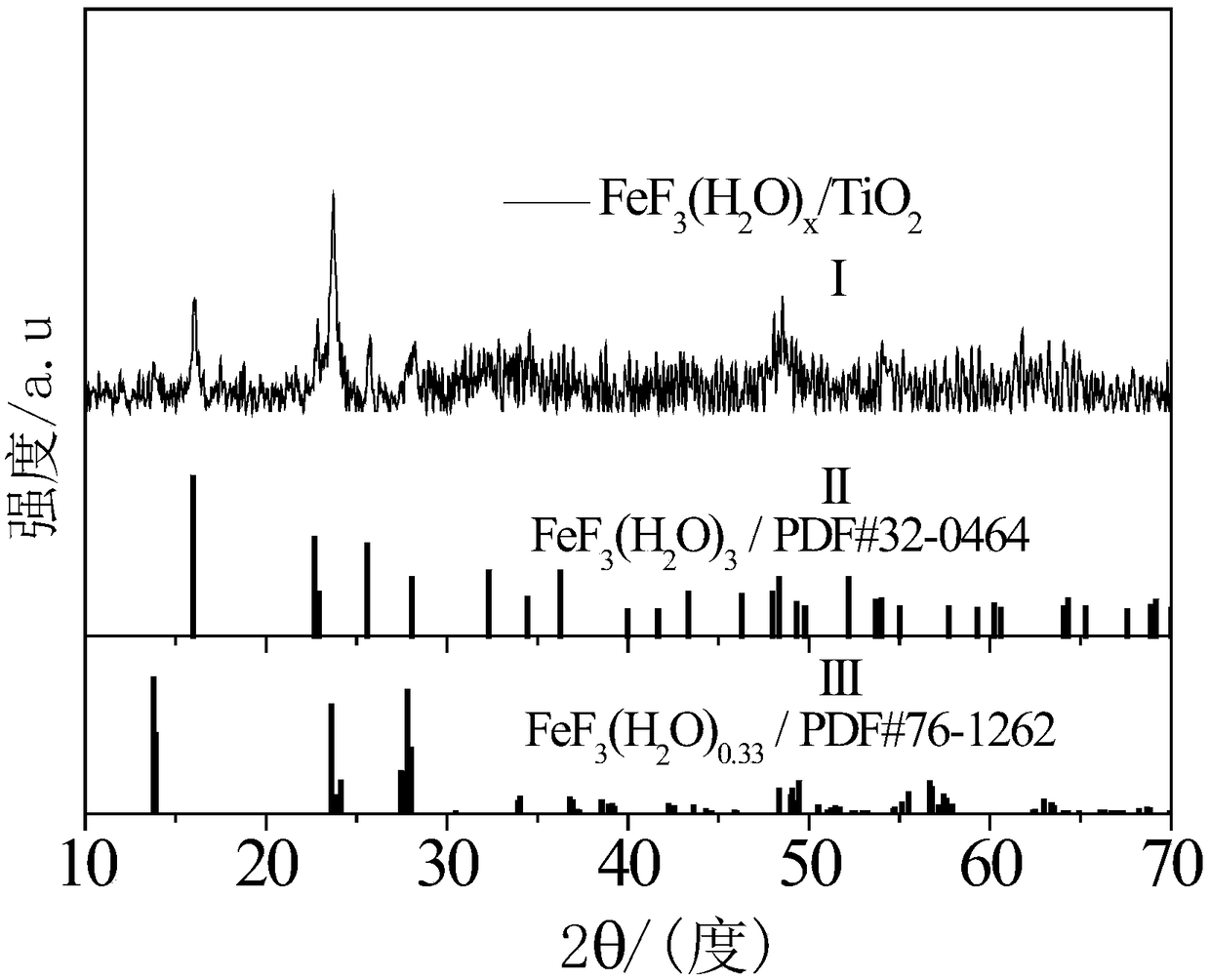

[0027] figure 1 It is the XRD spectrum of synth...

Embodiment 2

[0040] First weigh 0.05gTiO 2 It was completely dissolved in 15ml of distilled water, and it was a milky white liquid. Then it was allowed to stand for 6 hours, and then 2mg of dodecyltrimethylammonium bromide and 10.1g of Fe(NO 3 ) 3 .9H 2 O was stirred with a glass rod in an ultrasonic wave to dissolve it completely, and it appeared as a brownish-yellow liquid; after stirring for 20 minutes, it was placed in a polytetrafluoroethylene plastic bottle, and 5.43ml of hydrofluoric acid with a mass fraction of 40% was added to become colorless, and stirred After 12 hours, it turns into a pink liquid; add isopropanol dropwise until the solution turns into a colorless liquid, stir for 30 minutes, then heat up to 90°C, heat and stir for 18 hours to evaporate excess hydrofluoric acid and water, and obtain light yellow FeF 3 (H 2 0) 4.5 / TiO 2 ; then vacuum-dried in a vacuum oven at 90°C for 18h, and then vacuum-dried in a vacuum oven at 110°C for 18h to obtain light green FeF 3 ...

Embodiment 3

[0042] First weigh 0.1gTiO 2 Completely dissolved in 30ml of distilled water, it was a milky white liquid, then let it stand for 10h, then added 4mg of octadecyltrimethylammonium chloride and 20.2g of Fe(NO 3 ) 3 .9H 2 O was stirred with a glass rod in an ultrasonic wave to dissolve it completely, showing a brownish yellow liquid; after stirring for 30 minutes, place it in a polytetrafluoroethylene plastic bottle, add 26.09ml of hydrofluoric acid with a mass fraction of 20% to become colorless, stir After 18 hours, it turns into a pink liquid; add isopropanol dropwise until the solution turns into a colorless liquid, stir for 30 minutes, then heat up to 100°C, heat and stir for 12 hours to evaporate excess hydrofluoric acid and water, and obtain light yellow FeF 3 (H 2 0) 4.5 / TiO 2 ; then vacuum-dried in a vacuum oven at 100°C for 12h, and then vacuum-dried in a vacuum oven at 130°C for 12h to obtain light green FeF 3 (H 2 0) X / TiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com