Circular table magnetic separation column and iron concentrate sorting method based on circular table magnetic separation column

A magnetic separation column and separation technology, which is applied in the field of round table magnetic separation column and iron concentrate separation, can solve the problems of disturbed separation process, turbulent flow, high grade tailings of variable diameter magnetic separation column, etc., and achieve improved separation High efficiency, lower tailings grade, good sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

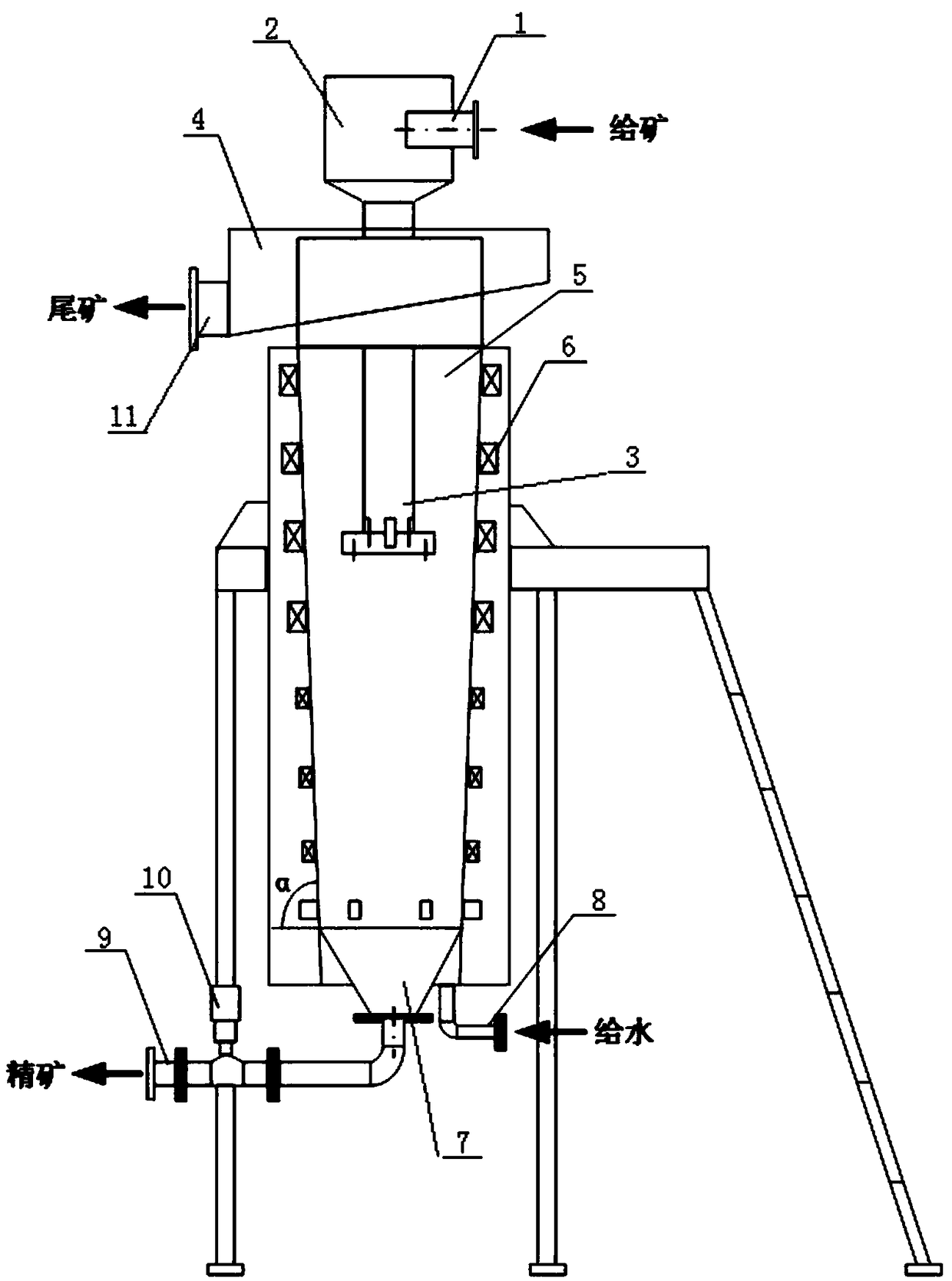

Embodiment 1

[0030] In this embodiment, the magnetite ore that needs to be separated is the magnetic separation concentrate obtained through two-stage magnetic separation, the grade is 61.05%, and it is separated by using a circular table magnetic separation column. The process is as follows:

[0031] Set the working parameters of the round table magnetic separation column: start the electromagnetic control system of the round table magnetic separation column, set the fixed current 2A, the circulating current 4A, the cycle time of one cycle is 6s, the concentration of ore is 40%, the opening of the water supply valve is 80%, the concentrate The electric valve 10 opening degree on the discharge pipe 9 is 50%. Start the round table magnetic separation column, the concentrate is discharged from the concentrate discharge pipe 9 at the bottom of the round table magnetic separation column to become the concentrate product of the magnetic separation column, and the tailings are discharged from the...

Embodiment 2

[0034] In this embodiment, the magnetite ore that needs to be separated is the magnetic separation concentrate obtained through magnetic separation, and the grade is 64.25%. It is separated by a circular table magnetic separation column, and the process is as follows:

[0035] Set the working parameters of the round table magnetic separation column: start the electromagnetic control system of the round table magnetic separation column, set a fixed current of 1.5A, a circulating current of 8A, a cycle time of 7s, a feeding concentration of 55%, a water supply valve opening of 70%, and a precision The opening of the electric valve on the mine discharge pipe is 60%. Start the round table magnetic separation column, the concentrate is discharged from the concentrate discharge pipe 9 at the bottom of the round table magnetic separation column to become the concentrate product of the magnetic separation column, and the tailings are discharged from the tailings discharge pipe 11 on th...

Embodiment 3

[0038] In this embodiment, the magnetite ore that needs to be sorted is obtained through magnetic separation, and the grade is 63.52%. It is sorted by a circular table magnetic separation column, and the process is as follows:

[0039] Set the working parameters of the round table magnetic separation column: start the electromagnetic control system of the round table magnetic separation column, set a fixed current of 3A, a circulating current of 10A, a cycle time of 8s, a feeding concentration of 45%, a water supply valve opening of 70%, and concentrate discharge The electric valve opening on the pipe is 55%. Start the round table magnetic separation column, the concentrate is discharged from the concentrate discharge pipe 9 at the bottom of the round table magnetic separation column to become the concentrate product of the magnetic separation column, and the tailings are discharged from the tailings discharge pipe 11 on the upper part of the round table magnetic separation col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com