Method for strengthening and solidifying chromium in chromium-containing waste

A waste, high temperature curing technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as land encroachment, vegetation destruction, soil erosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

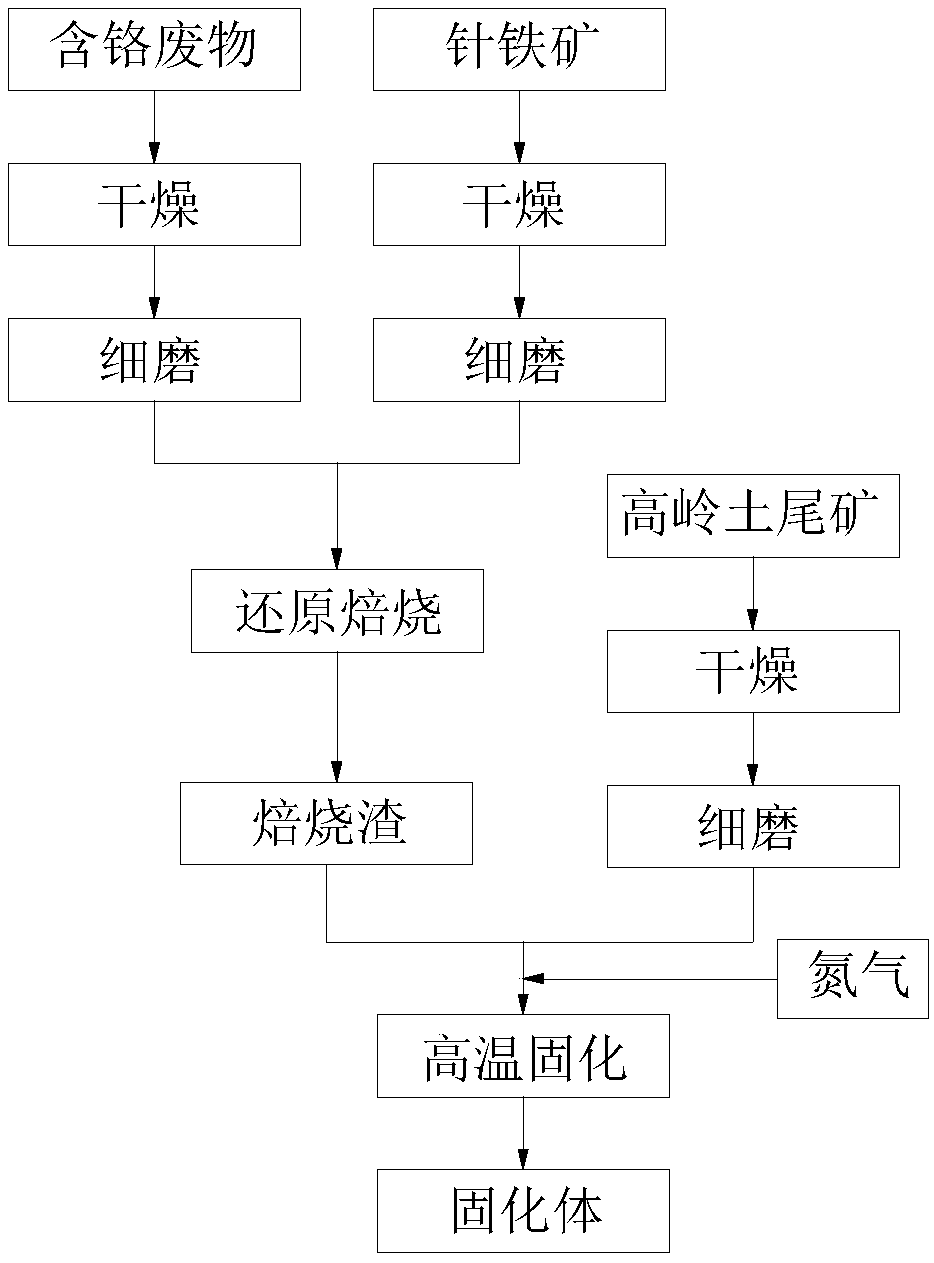

[0033] In this example, chromium-containing sludge was treated as the treatment object, and the waste was disposed of through dual solidification treatment of mineralization and high-temperature solidification to reduce the leaching toxicity of chromium in the solidified body. Such as figure 1 As shown, the specific method is as follows:

[0034] Dry the chromium-containing sludge, goethite and kaolin tailings to reduce the moisture content of the chromium-containing sludge, goethite and kaolin tailings from 70%, 30% and 35% to below 10% respectively; and adopt The ball mill grinds the dry chromium-containing sludge, goethite and kaolin tailings to -45μm respectively.

[0035] One portion of chromium-containing sludge and goethite are mixed uniformly at a dry basis mass percentage of 50%:50%, and the mixed material is added to a tube furnace for reduction roasting. The reducing gas is carbon monoxide, and the roasting temperature is 700 ° C. The roasting time is for 4 hours....

Embodiment 2

[0043] In this embodiment, chromium slag is used as the treatment object, and waste disposal is carried out through dual curing treatment of mineralization and high temperature curing to reduce the toxicity of chromium leaching in the solidified body. The specific method is as follows:

[0044]Dry the chromium slag, goethite and kaolin tailings to reduce the moisture content of chromium slag, goethite and kaolin tailings from 55%, 30% and 35% to below 10% respectively; Chromium slag, goethite and kaolin tailings are finely ground to -45μm; chromium slag and goethite are mixed uniformly at a dry basis mass percentage of 40%:60%, and the mixture is added to a tube furnace for reduction roasting, reduction The gas is carbon monoxide, the calcination temperature is 750°C, and the calcination time is 4.5 hours. The roasted slag obtained by roasting and kaolin tailings are mixed uniformly at a dry basis mass percentage of 18%:82% to obtain a secondary mixture, and are cured at a hi...

Embodiment 3

[0047] In this embodiment, the chromium salt slag is treated as the treatment object, and waste disposal is carried out through dual curing treatment of mineralization and high temperature curing to reduce the leaching toxicity of chromium in the solidified body. The specific method is as follows:

[0048] Dry chromium salt slag, goethite and kaolin tailings to reduce the moisture content of chromium salt slag, goethite and kaolin tailings from 45%, 30% and 35% to below 10% respectively; Dry chromium salt slag, goethite and kaolin tailings are finely ground to -45μm; chromium salt slag and goethite are mixed uniformly at a dry basis mass percentage of 45%:55%, and the mixture is added to a tube furnace for For reduction roasting, the reducing gas is carbon monoxide, the roasting temperature is 800° C., and the roasting time is 6 hours. The roasted slag obtained by roasting and kaolin tailings are mixed uniformly at a dry basis mass percentage of 22%:78% to obtain a secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com