A kind of water-based colorful paint and preparation method thereof

A water-based multi-color paint, active technology, applied in multi-color effect paint, coating and other directions, can solve the problems of whitening of the coating surface and color particles, superposition of negative effects of thickeners, easy water absorption on the surface of the coating, etc. Water absorption capacity, lower production cost, flexible and convenient viscosity adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

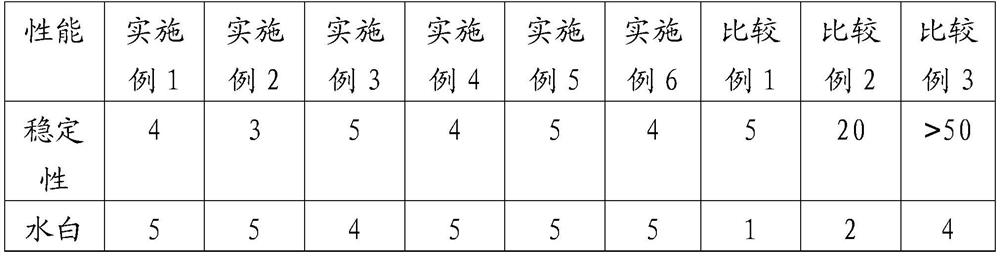

Examples

Embodiment 1

[0047] The water-based colorful paint of this embodiment includes a dispersed phase, a protective colloid solution and a continuous phase, and the mass ratio between the three is: 33:33:34.

[0048] 1. Preparation of protective colloid solution

[0049] Add 7 parts of S482 into 93 parts of deionized water, disperse under high-speed stirring for 0.5h-1h until completely dissolved to a colorless transparent solution, and set aside.

[0050] 2. Preparation of dispersed phase

[0051] The components and parts by mass of the dispersed phase are as follows:

[0052] 55 parts of deionized water, 0.4 part of defoamer (SN-154), 0.8 part of cellulose (250HBR), 0.1 part of pH regulator (AMP-95), 0.3 part of dispersant (731A), antifungal agent (DF- 19) 0.2 parts, 0.1 parts of fungicide (LX150), 0.5 parts of antifreeze (propylene glycol), 5 parts of pigments and fillers, anionic emulsion ( 8029) 32 parts, 0.6 parts of film-forming aid (Texanol), 5 parts of protective colloid solution (...

Embodiment 2

[0072] The water-based colorful paint of this embodiment includes a dispersed phase, a protective colloid solution and a continuous phase, and the mass ratio between the three is: 33:33:34.

[0073] 1. Preparation of protective colloid solution

[0074] Add 5 parts of S482 into 95 parts of deionized water, disperse under high-speed stirring for 0.5h-1h until completely dissolved to a colorless transparent solution, and set aside.

[0075] 2. Preparation of dispersed phase

[0076] The components and parts by mass of the dispersed phase are as follows:

[0077] 55 parts of deionized water, 0.4 part of defoamer (SN-154), 0.8 part of cellulose (250HBR), 0.1 part of pH regulator (AMP-95), 0.3 part of dispersant (731A), antifungal agent (DF- 19) 0.2 parts, 0.1 parts of fungicide (LX150), 0.5 parts of antifreeze (propylene glycol), 5 parts of pigments and fillers, anionic emulsion ( 8029) 32 parts, 0.6 parts of film-forming aid (Texanol), 5 parts of protective colloid solution (...

Embodiment 3

[0097] The water-based colorful paint of this embodiment includes a dispersed phase, a protective colloid solution and a continuous phase, and the mass ratio between the three is: 33:33:34.

[0098] 1. Preparation of protective colloid solution

[0099] Add 7 parts of GTS to 93 parts of deionized water, disperse under high-speed stirring for 0.5h-1h until completely dissolved to a colorless transparent solution, set aside.

[0100] 2. Preparation of dispersed phase

[0101] The components and parts by mass of the dispersed phase are as follows:

[0102] 55 parts of deionized water, 0.4 part of defoamer (SN-154), 0.8 part of cellulose (250HBR), 0.1 part of pH regulator (AMP-95), 0.3 part of dispersant (731A), antifungal agent (DF- 19) 0.2 parts, 0.1 parts of fungicide (LX150), 0.5 parts of antifreeze (propylene glycol), 5 parts of pigments and fillers, anionic emulsion ( 8029) 32 parts, 0.6 parts of film-forming aid (Texanol), 5 parts of protective colloid solution (S482); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com