A kind of humic acid nano zero-valent iron soil cr pollution remediation agent and preparation method

A nanometer zero-valent iron and pollution remediation technology, which is applied in the restoration of polluted soil, site preparation methods, soil conditioning materials, etc., can solve the problems of no chromium pollution remediation agent and remediation method, destruction of microbial environment, and difficult soil remediation, etc. problems, to achieve the effect of promoting the formation of soil aggregate structure, improving soil fertility, reducing toxicity and biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

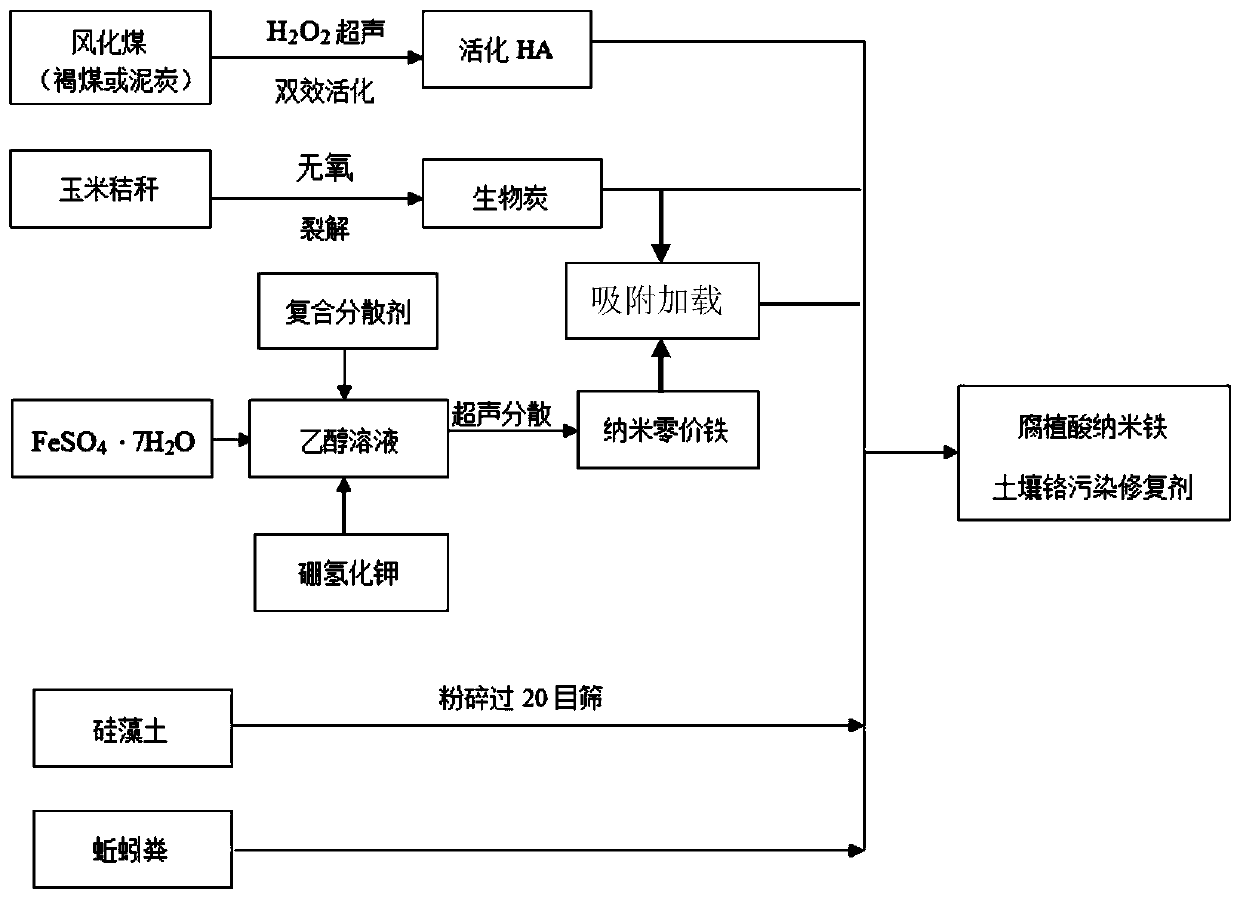

[0060] Embodiment 1: Preparation of humic acid nanometer zero-valent iron soil Cr pollution remediation agent

[0061] 1. Raw material composition:

[0062] 12 parts of activated humic acid, 15 parts of corn stalk biochar, 1.2 parts of nano-zero-valent iron, 15 parts of diatomaceous earth, and 15 parts of vermicompost.

[0063] 2. Preparation method:

[0064] (1) Preparation of activated humic acid:

[0065] With weathered coal as humic acid raw material, humic acid raw material and H2 with mass concentration of 2.5% 2 o 2 The diluent is mixed according to the weight ratio of 9:1. In the ultrasonic toner separator, the ultrasonic power is set to 200w, and the ultrasonic activation time is set to 20min to prepare activated humic acid.

[0066] (2) Preparation of corn stalk biochar:

[0067] Corn stalks were used as raw materials, crushed through a 2mm sieve, filled in a closed crucible, and anaerobically cracked in a muffle furnace at 350°C for 2 hours to obtain corn stalk...

Embodiment 2

[0072] Embodiment 2: Preparation of humic acid nanometer zero-valent iron soil Cr pollution remediation agent

[0073] 1. Raw material composition:

[0074] 10 parts of activated humic acid, 20 parts of corn stalk biochar, 1.6 parts of nano-zero-valent iron, 13 parts of diatomaceous earth, and 17 parts of vermicompost.

[0075] 2. Preparation method:

[0076] (1) Preparation of activated humic acid:

[0077] Taking weathered coal as the humic acid raw material, the humic acid raw material and the mass concentration of 2% H 2 o 2 The diluent is mixed according to the weight ratio of 7:1. In the ultrasonic toner separator, the ultrasonic power is set to 180w, and the ultrasonic activation time is set to 25min to prepare activated humic acid.

[0078] (2) Preparation of corn stalk biochar:

[0079] Corn stalks were used as raw materials, crushed through a 1mm sieve, filled in a closed crucible, and anaerobically cracked in a muffle furnace at 300°C for 3 hours to obtain corn...

Embodiment 3

[0084] Embodiment 3: Preparation of Humic Acid Nano Zero-valent Iron Soil Cr Pollution Restoration Agent

[0085] 1. Raw material composition:

[0086] 20 parts of activated humic acid, 10 parts of corn stalk biochar, 3 parts of nano-zero-valent iron, 10 parts of diatomaceous earth, and 25 parts of vermicompost.

[0087] 2. Preparation method:

[0088] (1) Preparation of activated humic acid:

[0089] Taking weathered coal as the humic acid raw material, the humic acid raw material and H with a mass concentration of 5% 2 o 2 The diluent is mixed according to the weight ratio of 8:1. In the ultrasonic toner separator, the ultrasonic power is set to 180w, and the ultrasonic activation time is set to 25min to prepare activated humic acid.

[0090] (2) Preparation of corn stalk biochar:

[0091] Corn stalks were used as raw materials, crushed through a 3 mm sieve, filled in a closed crucible, and anaerobically cracked in a muffle furnace at 400 °C for 1 h to obtain corn stalk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com