Sourdough bread composite fermentation agent, preparation method, application and bread prepared by using same

A compound starter and bread technology, applied in the food field, can solve the problems of unstable product quality, weak bread flavor, poor controllability of strains, etc., and achieve the effects of delaying dough aging, facilitating human body absorption and utilization, and improving nutritional quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

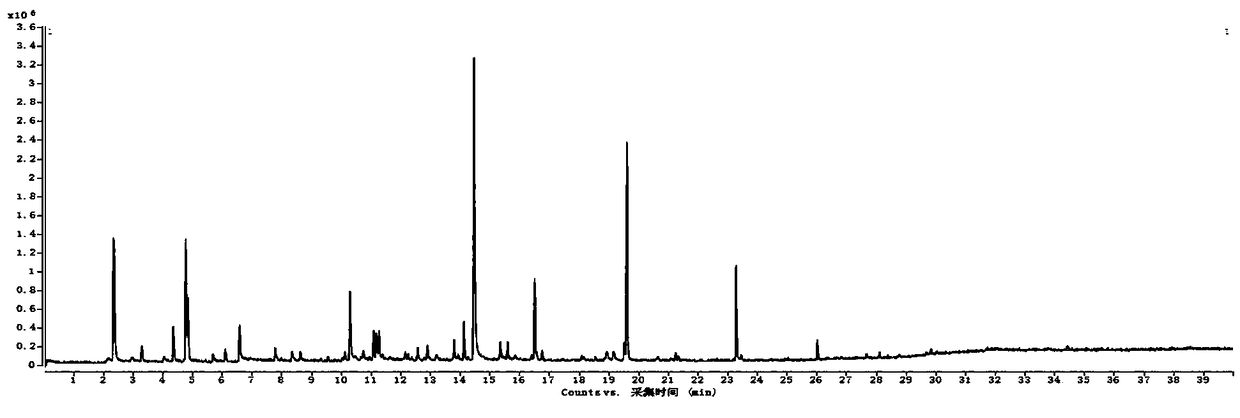

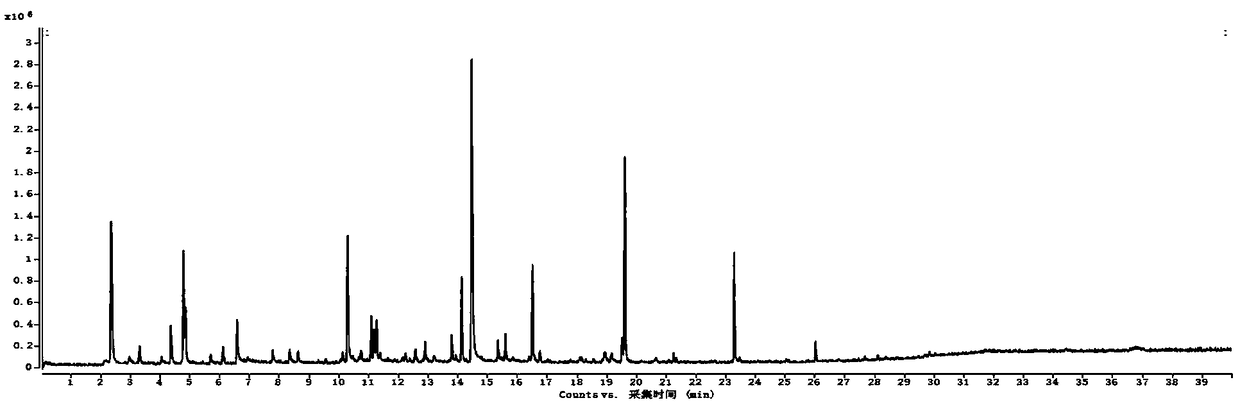

Image

Examples

Embodiment 1

[0062] A compound leavening agent for old dough bread, its raw material components and proportions are as follows:

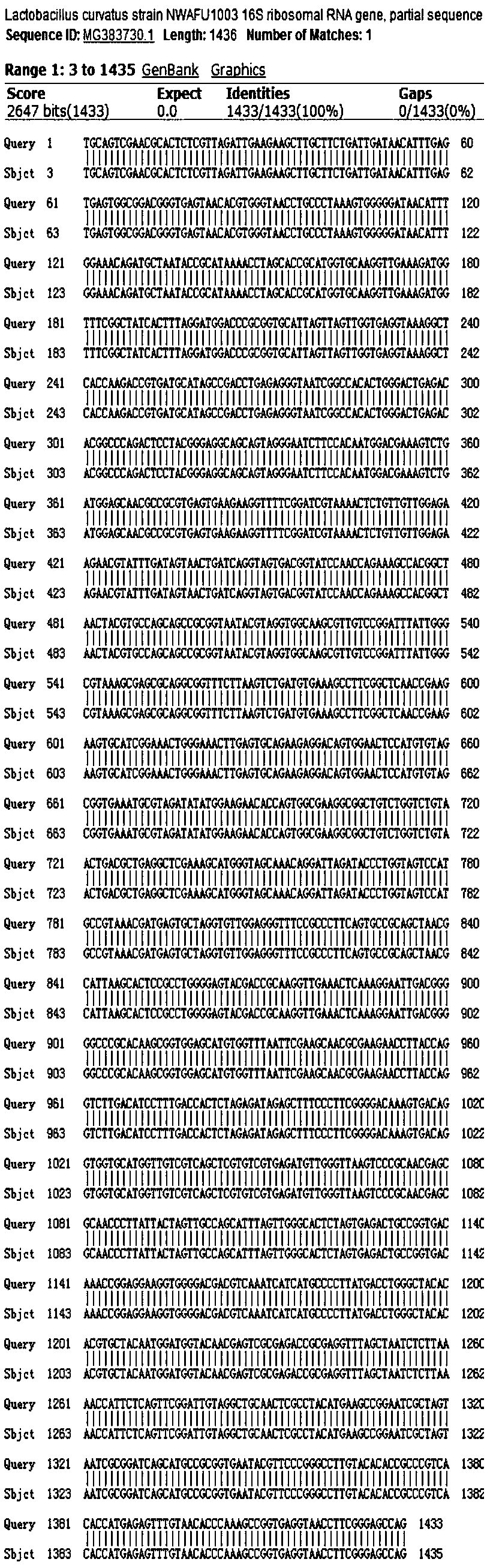

[0063] The ingredients of raw materials are: fermented strains Lactobacillus flexus, Lactobacillus brevis, yeast and freeze-drying protectant;

[0064] The cell number ratio of the fermented strain Lactobacillus flexus, Lactobacillus brevis and yeast is 1:1:1, and the weight ratio of the mixed sludge of Lactobacillus flexus and Lactobacillus brevis to the freeze-drying protective agent is 1:1 .

[0065] The Lactobacillus flexus and Lactobacillus brevis are all separated from the traditional old starter starter, and the concentrations of the Lactobacillus flexus and Lactobacillus brevis are respectively 2.21×10 9 CFU / mL, and 1.69×10 9 CFU / mL.

[0066] The usage of the old-noodle bread compound starter is as follows: add 17.6g of the old-noodle bread compound starter per 1kg of flour.

[0067] The preparation method of the above-mentioned old dough bread compo...

Embodiment 2

[0082] A compound leavening agent for old dough bread, its raw material components and proportions are as follows:

[0083] The ingredients of raw materials are: fermented strains Lactobacillus flexus, Lactobacillus brevis, yeast and freeze-drying protectant;

[0084] The cell number ratio of the fermentation strain Lactobacillus flexus, Lactobacillus brevis and yeast is 4:1:6, and the weight ratio of the mixed sludge of Lactobacillus flexus and Lactobacillus brevis to the freeze-drying protective agent is 1:3 ; The bacterium concentration of described lactobacillus flexus and lactobacillus brevis is respectively 4.42 * 10 10 CFU / mL, and 3.37×10 10 CFU / mL.

[0085] The Lactobacillus flexus and Lactobacillus brevis are all isolated from the traditional old starter starter.

[0086] The preparation method of the above-mentioned old dough bread compound starter, the steps are as follows:

[0087] (1) Activation and cultivation of strains: Pick Lactobacillus flexus and Lactoba...

Embodiment 3

[0101] A compound leavening agent for old dough bread, its raw material components and proportions are as follows:

[0102] The ingredients of raw materials are: fermented strains Lactobacillus flexus, Lactobacillus brevis, yeast and freeze-drying protectant;

[0103] The cell number ratio of the fermentation strain Lactobacillus flexus, Lactobacillus brevis and yeast is 3:1:5, and the weight ratio of the mixed sludge of Lactobacillus flexus and Lactobacillus brevis to the freeze-drying protective agent is 1:1 . The bacterial concentration of the Lactobacillus flexus and Lactobacillus brevis were 3.98×10 10 CFU / mL, and 2.87×10 10 CFU / mL.

[0104] The Lactobacillus flexus and Lactobacillus brevis are all separated from the traditional old-bread starter starter, and the usage of the old-bread composite starter is as follows: add 27.3 g of the old-bread composite starter per 1 kg of flour.

[0105] The preparation method of the above-mentioned old dough bread compound starter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com