Ink jet printing paper and painting thereof

A technology of inkjet printing and printing paper, applied in paper coating, printing, application, etc., can solve the problems of fine coating, good dispersion, high solid content of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0107] Table 1 shows the formulations of topcoat coatings, formulations of coatings used for coated paper coatings, and types of coated paper base paper used in Examples 1 to 3.

[0108] Among them, the ash in the coated paper base paper is a mixture of ground calcium carbonate and precipitated calcium carbonate.

[0109] The preparation methods of the coating used for the top coating and the coated paper coating are conventional in the field, and each component is mixed uniformly.

[0110] Precipitated calcium carbonate is used as the pigment of the ink-jet receiving surface coating, and an appropriate anionic dispersant is added to adjust the PCD value of the pigment particles to be between -100 and 0 μeq / L. The embodiment uses a physical method to adjust the size of the pigment particles to a D50 of 0.4-0.8 μm. In terms of mass percentage, more than 60% of the pigment particles are larger than 0.2 μm, and the mass accumulation percentage of the pigments with a particle size...

Embodiment 4

[0119] Except that there are differences in the following operations or parameters, others are the same as in Example 1.

[0120] Preparation of ink-jet printing paper: on both sides of base paper, coating top coating (the coating amount of each side is 24g / m 2 ), after drying and calendering, top coats are formed on both sides of the base paper respectively to obtain inkjet printing paper. In the coating process of the top coat layer, the number of times of coating is not limited, and may be one coating or multiple coatings.

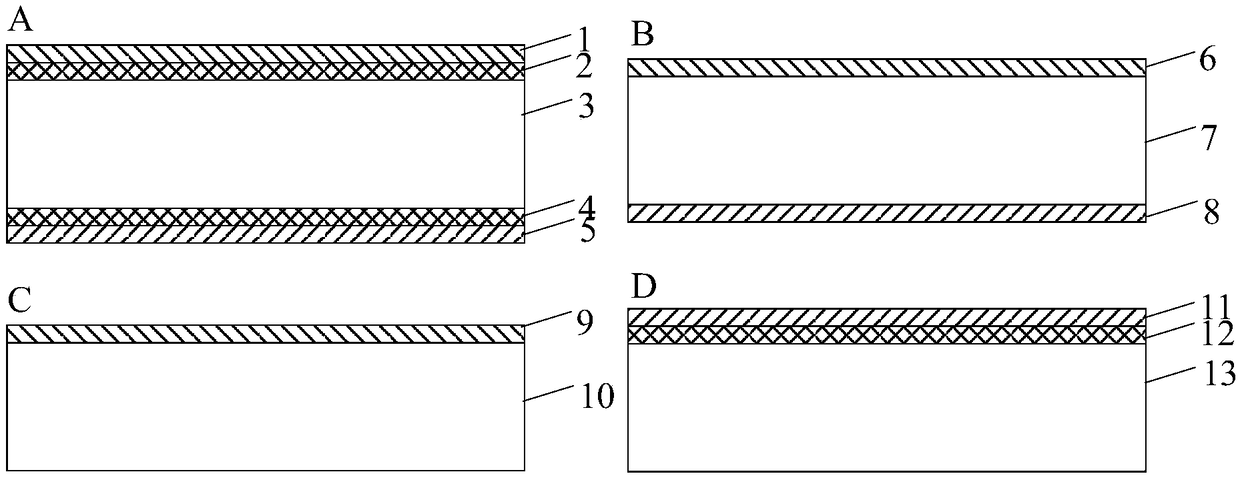

[0121] The structure of inkjet printing paper includes: the first surface coating, base paper, and the second surface coating. Such as figure 1 As shown in B, among them, 6 is the first surface coating, 7 is the base paper, and 8 is the second surface coating.

[0122] Among them, in the base paper, the grammage is 55g / m 2 , the ash content is 14%, and the Cobb value is 21g / m 2 , table glue.

Embodiment 5

[0124] Except that there are differences in the following operations or parameters, others are the same as in Example 1.

[0125] A paper for inkjet printing, its structure includes a base paper, one side of the base paper contains one side coating, such as figure 1 Shown in C, wherein, 9 is the surface coating, and 10 is the base paper. The coating amount of the top coat is 24g / m 2 . Among them, in the base paper, the grammage is 55g / m 2 , the ash content is 14%, and the Cobb value is 21g / m 2 , table glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com