Underground garage waterproof and moisture-proof paving structure and construction process thereof

An underground garage and pavement technology, applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of degumming of epoxy floor bonding surface, increased maintenance and repair costs, poor ground surface compactness, etc., to prevent moisture Even water accumulation, complete isolation of water and moisture, and the effect of large drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

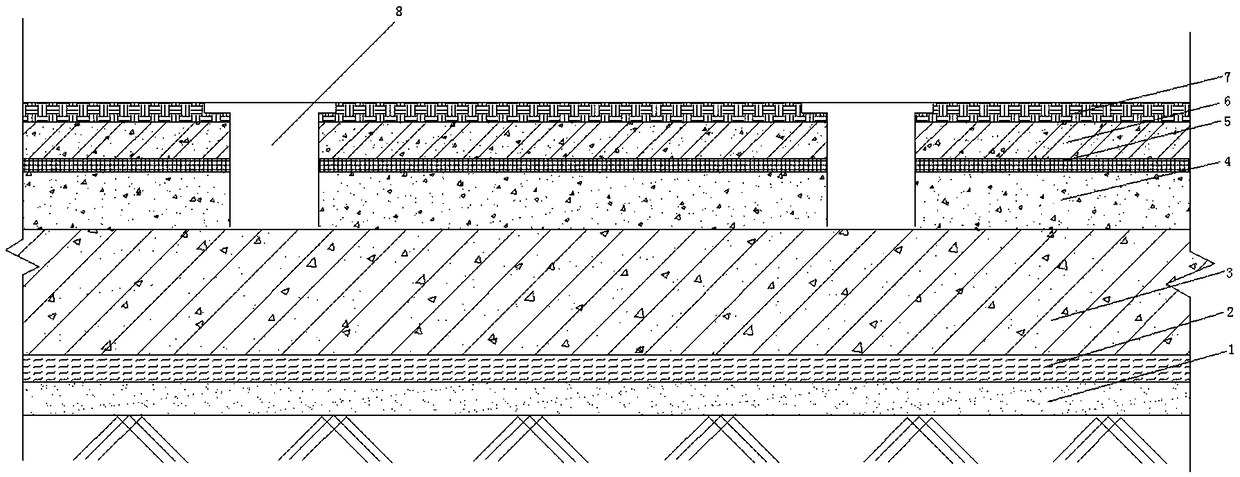

[0031] Such as figure 1 As shown, a waterproof and moisture-proof pavement structure for an underground garage is provided with a plain concrete cushion layer 1, a flexible waterproof layer 2, a structural self-waterproof layer 3, a water-filtering concrete layer 4, a flexible supporting layer 5, and an anti-corrosion layer from bottom to top. crack moisture-proof layer 6 and floor surface layer 7, and the structure is provided with drains 8 in the structural layer above the waterproof layer.

[0032] Specifically, the plain concrete cushion 1 has a thickness of 80 mm and is evenly spread on the base surface. After the concrete is vibrated and compacted, the surface is smoothed with a wooden trowel, and the construction of the upper layer begins after the curing is completed.

[0033] Specifically, the flexible waterproof layer 2 is a synthetic polymer coil or a modified asphalt coil, and the coils are bonded by hot melt, and the coils are bonded to the plain concrete cushion...

Embodiment 2

[0055] Such as figure 1 As shown, a waterproof and moisture-proof pavement structure for an underground garage, which is sequentially provided with a plain concrete cushion 1, a flexible waterproof layer 2, a structural self-waterproof layer 3, a water-filtering concrete layer 4, a flexible supporting layer 5, and a crack-resistant and moisture-proof layer 6 And the floor surface layer 7, the structure is provided with a drainage ditch 8 in the structural layer above the waterproof layer.

[0056] Specifically, the flexible waterproof layer 2 is cement-based flexible waterproof mortar, and the cement-based flexible waterproof mortar is poured and laid on the plain concrete cushion with a thickness of 2mm. When the flexible waterproof layer 2 is subjected to an external force, the cement-based flexible waterproof mortar itself has a certain degree of stretching and ductility, and can resist cracking of the base layer within the elastic range of the waterproof material, showing ...

Embodiment 3

[0066] A waterproof and moisture-proof pavement structure for an underground garage, which is sequentially provided with a plain concrete cushion 1, a flexible waterproof layer 2, a structural self-waterproof layer 3, a water-filtering concrete layer 4, a flexible supporting layer 5, a crack-resistant and moisture-proof layer 6 and a floor The surface layer 7, the structure is provided with a drainage ditch 8 in the structural layer above the waterproof layer.

[0067] The water-filtering concrete layer 4 in this embodiment is different from the water-filtering concrete layer 4 in Embodiment 1. The water-filtering concrete is composed of the following raw materials in mass percentage: 15mm single-graded basalt gravel 76.5%, P.O 42.5 cement 16.5% %, reinforcing material 0.70%, basalt chopped fiber with a fiber length of 10mm 0.30%, 100 mesh waste tire rubber powder 0.7%, water 5.3%; the reinforcing material is composed of the following raw materials in mass percentage: silica fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com