Device for evaporative crystallization and crystallization method of ethyl maltol

A technology of ethyl maltol and evaporative crystallization, applied in evaporative separation crystallization, solution crystallization, organic chemistry, etc., can solve the problems of low production efficiency, large product quality differences, and many steps, and achieve the promotion of precipitation and regular distribution of flow field orderly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

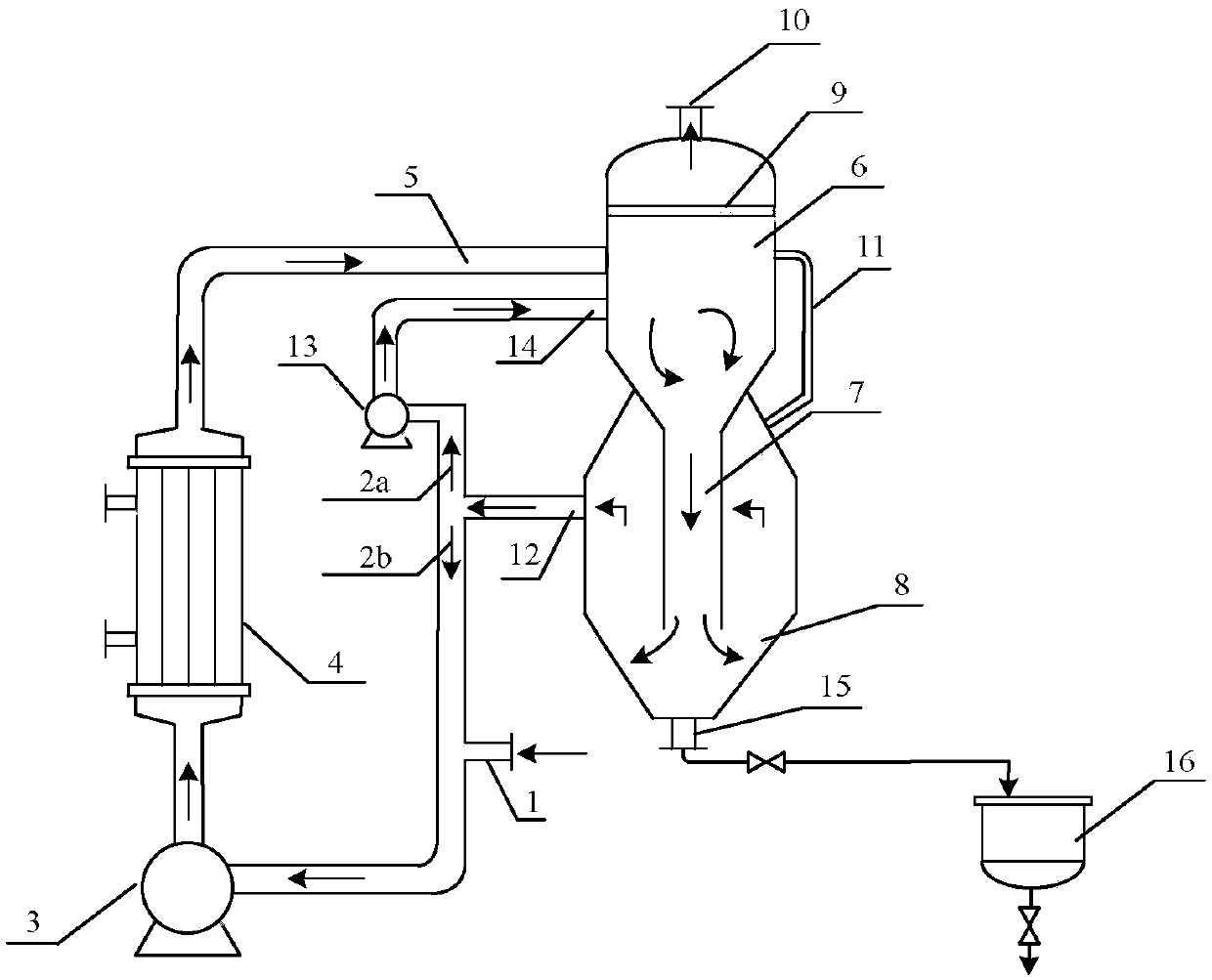

[0079] This embodiment adopts as figure 1 The shown device for evaporative crystallization carries out the crystallization operation, specifically according to the following steps:

[0080] (1) The ethyl maltol crude product with a purity of 87% was dissolved in water, decolorized and filtered to obtain a raw material solution of ethyl maltol with a concentration of 14% by mass, and the temperature was 35°C.

[0081] (2) Turn on the heater 4, pump the raw material liquid of ethyl maltol from the raw material liquid inlet pipe 1, and transport it to the heater 4 through the second circulation pump 3, and the temperature of the raw material liquid rises to 62°C. The heated raw material liquid continuously flows into the evaporation vessel 6 at a rate of 240kg / h.

[0082] (3) Control the vacuum degree of evaporation container 6 to be 0.065MPa, make raw material liquid enter boiling state after entering evaporation container 6, ethanol evaporation rate is maintained at 157kg / h, s...

Embodiment 2

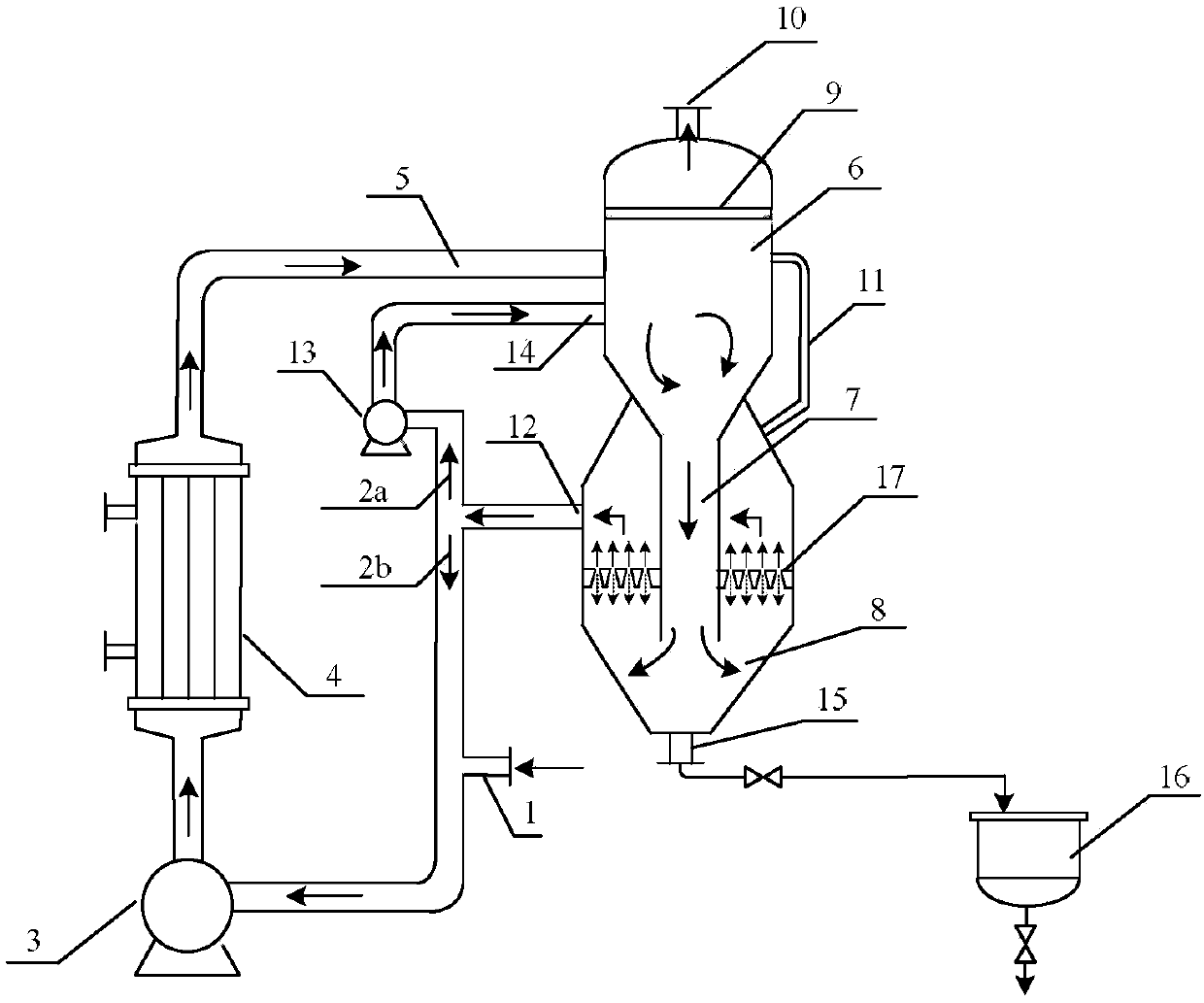

[0087] This embodiment adopts as figure 2 The shown device for evaporative crystallization carries out the crystallization operation, specifically according to the following steps:

[0088] (1) The ethyl maltol crude product with a purity of 87% was dissolved in an ethanol solvent, decolorized and filtered to obtain a raw material solution of ethyl maltol with a concentration of 14% by mass, and the temperature was 35°C.

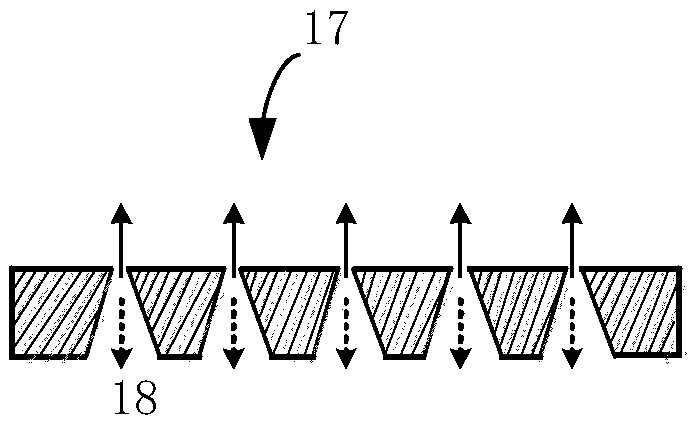

[0089] (2) Turn on the heater 4, pump the raw material liquid of ethyl maltol from the raw material liquid inlet pipe 1, and transport it to the heater 4 through the second circulation pump 3, and the temperature of the raw material liquid rises to 62°C. The heated raw material liquid continuously flows into the evaporation vessel 6 at a rate of 240kg / h. The diameter of the upper end of the channel 18 is 5 mm, the ratio of the diameter of the lower end of the channel 18 to the diameter of the upper end of the channel 18 is 1.8:1, and the opening ratio of t...

Embodiment 3

[0095] On the basis of embodiment 2, the flow rate of the first circulating pump 13 of step (3) is set to 417kg / h, and the ratio control of the flow rate of the flow of the first stream and the flow of the second stream is 0.4, step ( 5) The flow rate of the first circulating pump 13 is controlled at 384kg / h, and the ratio of the flow rate of the first stream to the second stream is controlled to be 0.4; all the other conditions are the same as in Example 2. The resulting filter cake was dried to obtain white ethyl maltol crystalline particles with a purity of 97.8%. The crystallization yield was 89.5% based on the amount of feed, and the 60-mesh pass rate of ethyl maltol crystalline particles was 85.8%. , The pass rate of 80 mesh is 32%, and the pass rate of 120 mesh is 0.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com