A kind of high dielectric ceramic capacitor material with high temperature stability and preparation method thereof

A ceramic capacitor and stability technology, applied in the field of electronic ceramics, can solve problems such as poor temperature stability, achieve the effect of improving temperature stability, green raw materials, and suitable for large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

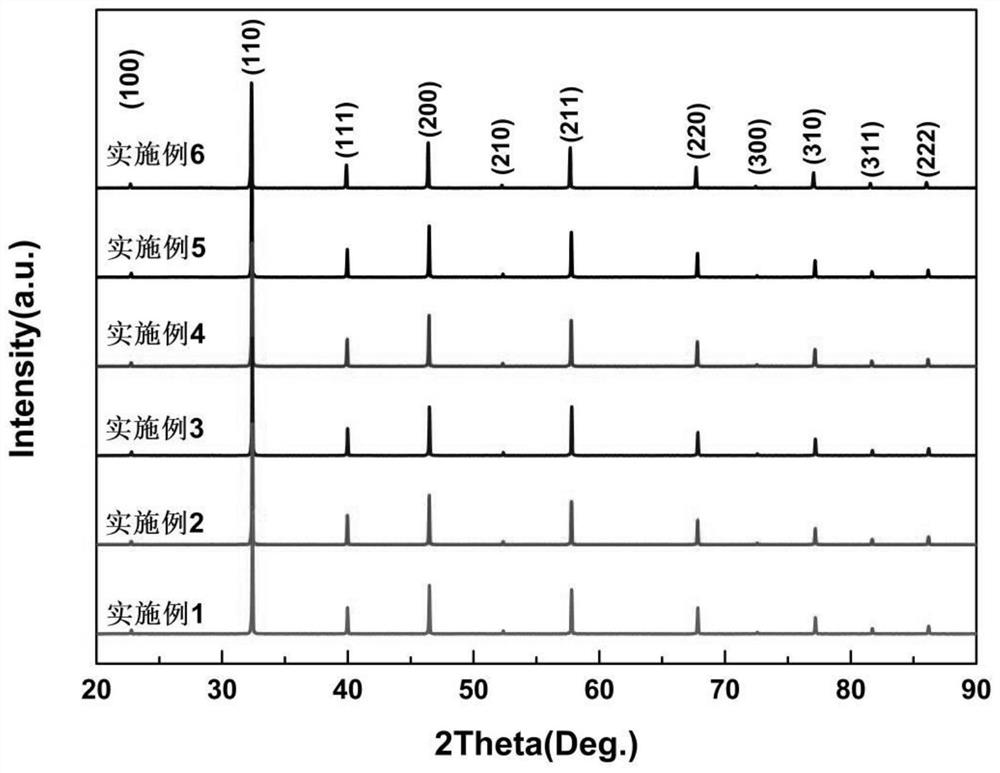

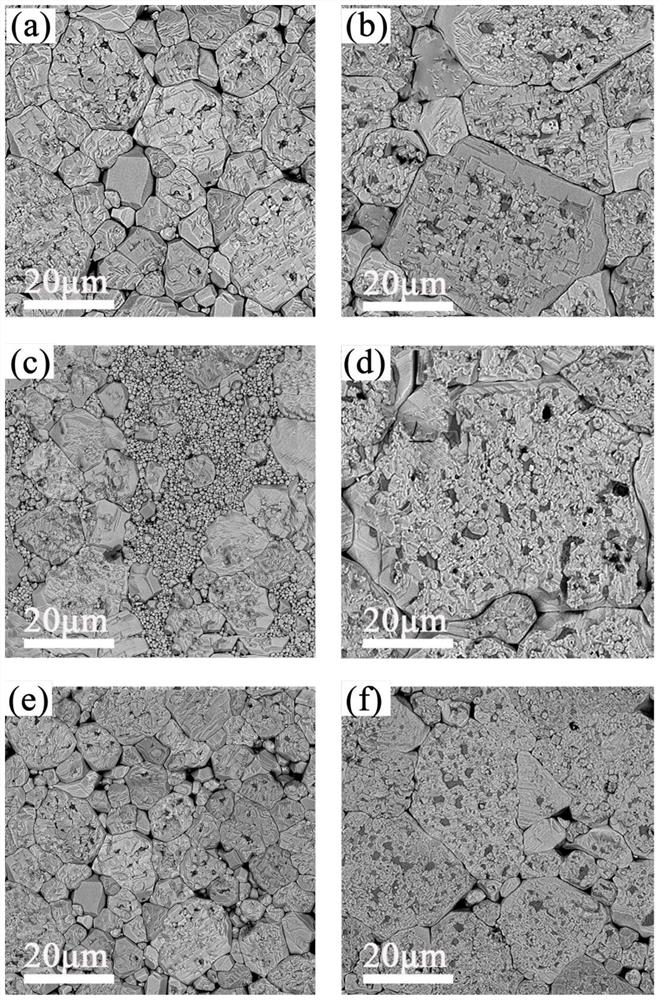

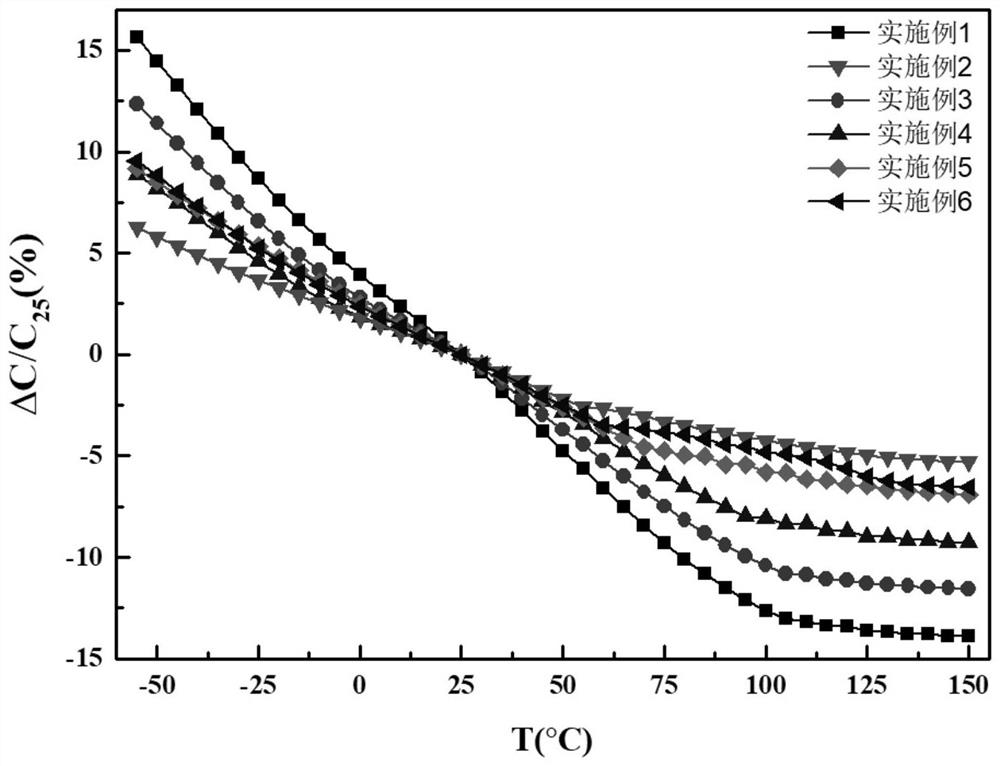

Embodiment 1

[0054] As a comparative example, this embodiment provides a method for preparing a high-dielectric ceramic capacitor material, and the specific operations are as follows:

[0055] Step 1: SrCO 3 ,TiO 2 The powder was prepared according to the molar ratio of 1:1, deionized water was used as the solvent, zirconia balls were used as the ball milling medium, and SrCO 3 and TiO 2 Powder ball milling, the ratio of material: ball: water is 1:4:1.5, and the ball milling time is 24 hours;

[0056] Step 2: Place the ball-milled mixture in an oven to dry at 120°C, pass through a 40-mesh sieve, and pre-fire the sieved material in air at a sintering temperature of 1250°C and a holding time of 2 hours to obtain the base material;

[0057] Step 3: Add 0.05g Nb to 100g base material 2 o 5 , 0.10gTa 2 o 5 , mix the prepared doping material with the base material, the ratio of material: ball: water is 1:4:1.5, ball mill for 6 hours, place in an oven to dry at 120°C, and pass through a 4...

Embodiment 2

[0062] This embodiment provides a method for preparing a high-dielectric ceramic capacitor material, and the specific operations are as follows:

[0063] Step 1: SrCO 3 ,TiO 2 The powder was prepared according to the molar ratio of 1:1, deionized water was used as the solvent, zirconia balls were used as the ball milling medium, and SrCO 3 and TiO 2 Powder ball milling, the ratio of material: ball: water is 1:4:1.5, and the ball milling time is 24 hours;

[0064] Step 2: Place the ball-milled mixture in an oven to dry at 120°C, pass through a 40-mesh sieve, and pre-fire the sieved material in air at a sintering temperature of 1250°C and a holding time of 2 hours to obtain the base material;

[0065] Step 3: Add CaCO 3 , SiO 2 , Al 2 o 3 and H 3 BO 3The four components are ball milled, dried, and sieved to obtain a mixture, and then the mixture is used to pre-synthesize glass at 1450 ° C. The specific operation is as follows: 0% to 30% CaCO 3 , 20% to 50% Al 2 o 3 ...

Embodiment 3

[0071] This embodiment provides a method for preparing a high-dielectric ceramic capacitor material, the operation of which is basically the same as that of Embodiment 2, except for the composition of the CABS glass powder, which is shown in Table 1 below in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| loss value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com