Polyurethane modified epoxy resin diluent and low viscosity high toughness epoxy resin composition composed thereof

A polyurethane modification and epoxy resin technology, applied in the field of epoxy resin, can solve the problems of reducing the epoxy value of the product, large difference, difficult to control continuous addition side reactions, etc., and achieve good dilution effect and improved bending strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For a better understanding of the present invention, the following examples are further descriptions of the present invention, but the content of the present invention is not limited to the following examples.

[0031] Preparation of polyurethane modified 669 diluent:

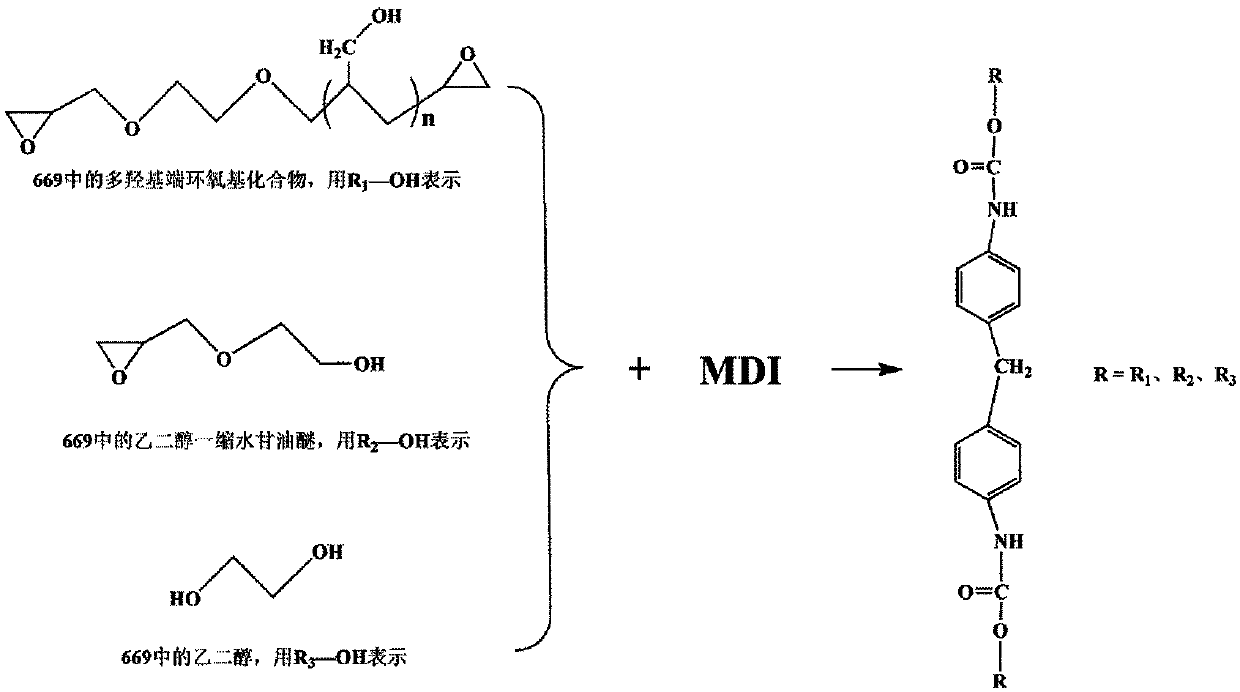

[0032] The hydroxyl value range of 669 measured by the acetic anhydride-sulfuric acid method is 0.06-0.10. The dehydrated 669 is placed in a three-necked flask, and the double-distilled MDI is placed in a constant pressure separatory funnel. According to n(NCO) : The ratio of n(OH)=1:1 is slowly added dropwise to the three-necked flask filled with 669, the stirring speed of the stirrer in the three-necked flask is 200rpm, and the N 2 protection, adjust the reaction temperature, and slowly increase the temperature of the reaction system from room temperature to 120° C., and keep the temperature for 4 hours to obtain the reaction product. figure 1 It is the reaction principle of polyurethane modified 669 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com