Post-posed splitting pupil laser differential confocal microscopic detection method and device

A differential confocal and microscopic detection technology, applied in the direction of measuring devices, analytical materials, material excitation analysis, etc., can solve the problems of limited measurement accuracy, light source intensity fluctuations, poor confocal intensity response sensitivity, and decreased spatial resolution. , to achieve the effects of measuring range and resolution, simplifying the detection optical system, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

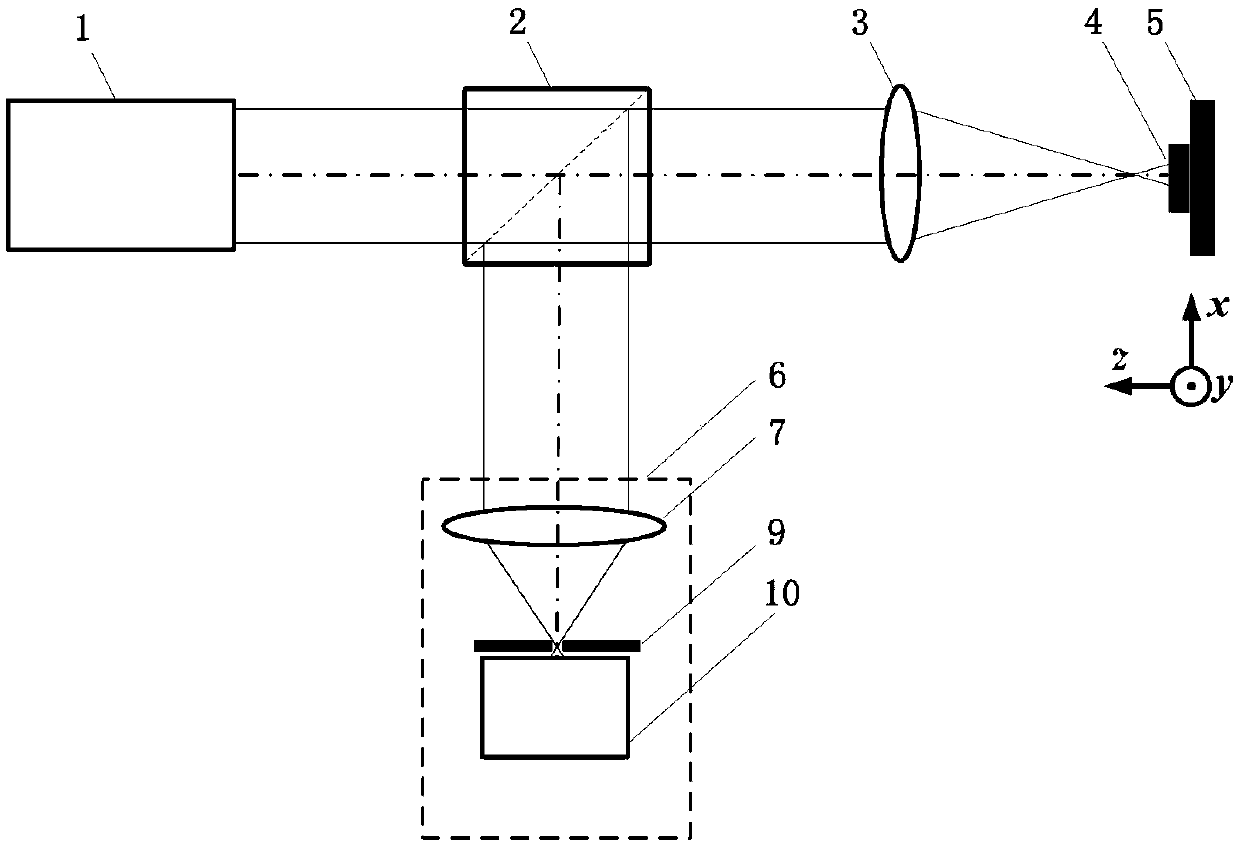

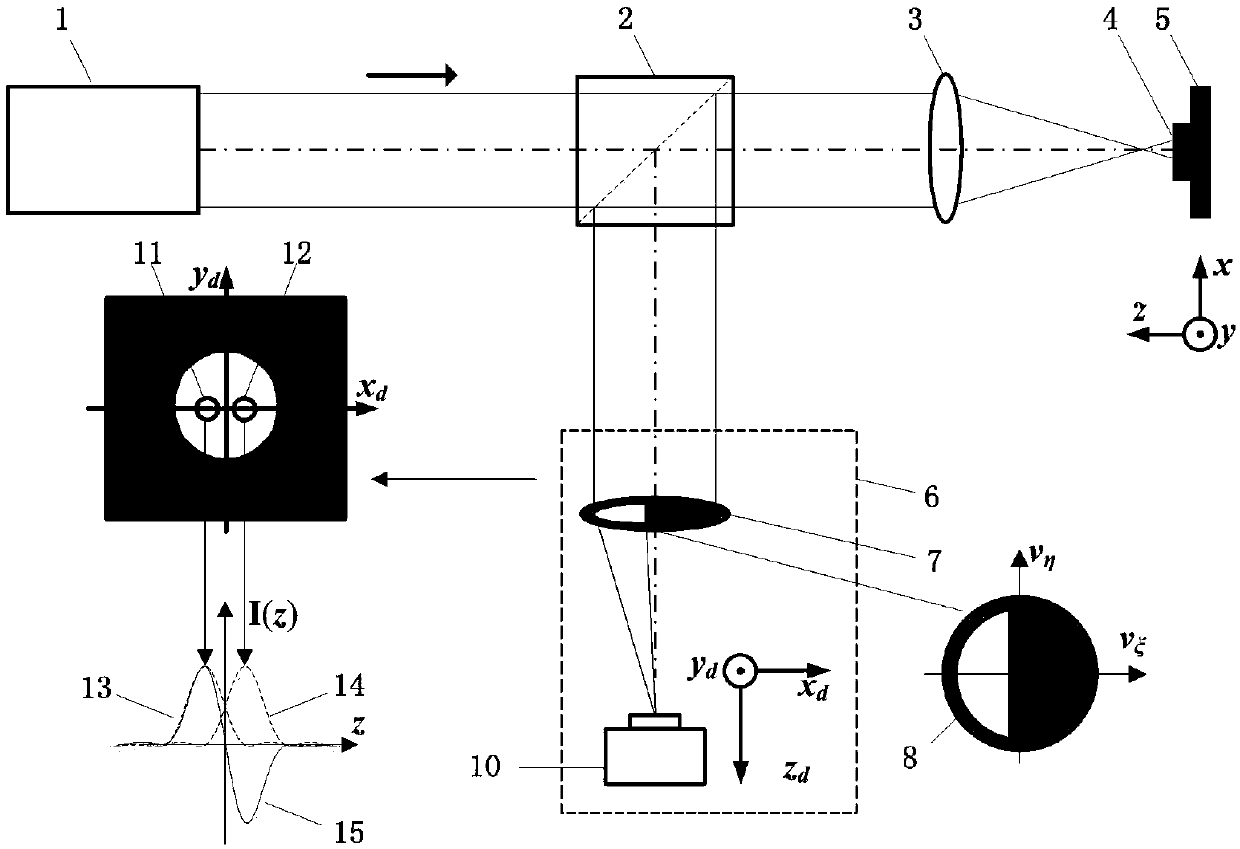

[0048] Such as image 3 As shown, the rear collecting pupil 8 is placed on the pupil plane of the first converging lens 7, and the excitation beam emitted by the light source system 1 passes through the dichroic prism 2 and the measuring objective lens 3, then converges on the measured sample 4, and is reflected out of the carrier. The reflected light with the geometric shape information of the sample enters the rear split-pupil laser differential confocal detection system 6, passes through the first converging lens 7 and the rear collection pupil 8, and is focused by the light intensity acquisition system 10 Segmented detection to realize the detection of the geometric shape of the 4 micro-areas of the tested sample.

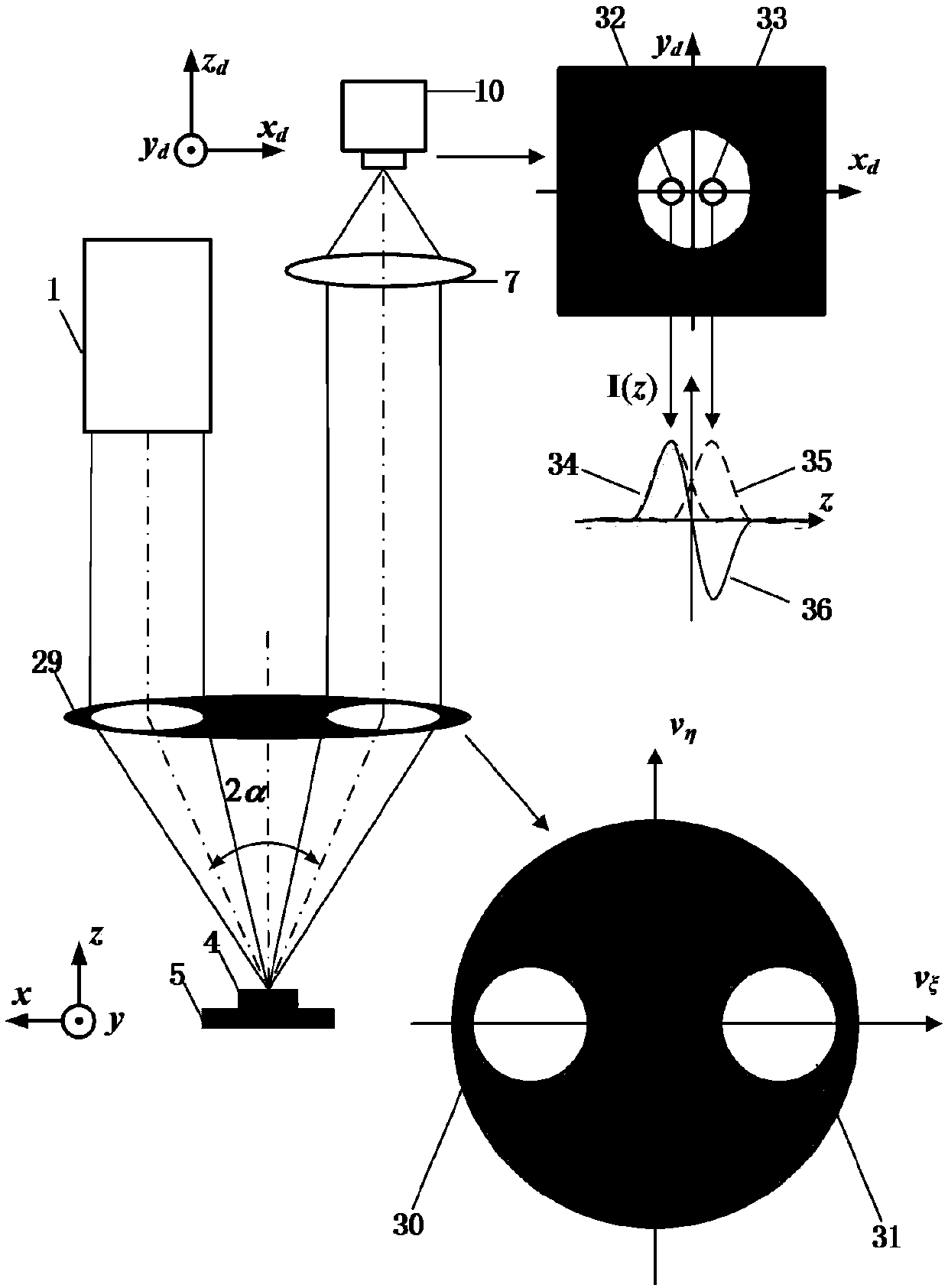

[0049] In particular, the rear collection pupil 8 can be replaced by other shapes, such as a circle, to form a rear circular split pupil laser differential confocal microscopic detection method, such as Figure 4 shown.

[0050] In particular, by adding a rad...

Embodiment 2

[0057] Such as Figure 11 As shown, the rear split pupil laser differential confocal microscope detection device includes a light source system 1 for generating an excitation beam, a beam modulation system 20, a radial polarization conversion system 18, a beam splitter prism 2, a pupil filter 19, a measuring objective lens 3, and a Test sample 4, three-dimensional scanning system 5, rear split pupil laser differential confocal detection system 6.

[0058] Above, along the laser emission direction of the light source system 1, the second converging lens 19, the second pinhole 20, the third converging lens 21, the radial polarization conversion system 16, the dichroic prism 2, the pupil filter 17, and the measuring objective lens are sequentially placed 3. The sample to be tested 4 and the three-dimensional scanning system 5 place the first converging lens 7, the rear collection pupil 8, the relay magnifier 22, and the CCD detector 25 in sequence in the reflection direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com