Non-contact measurement device and method for sound velocities of surface waves and plate waves

A non-contact, measurement method technology, applied in measurement devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. , application scope constraints, etc., to avoid human errors, strong signal processing and analysis functions, and easy system portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

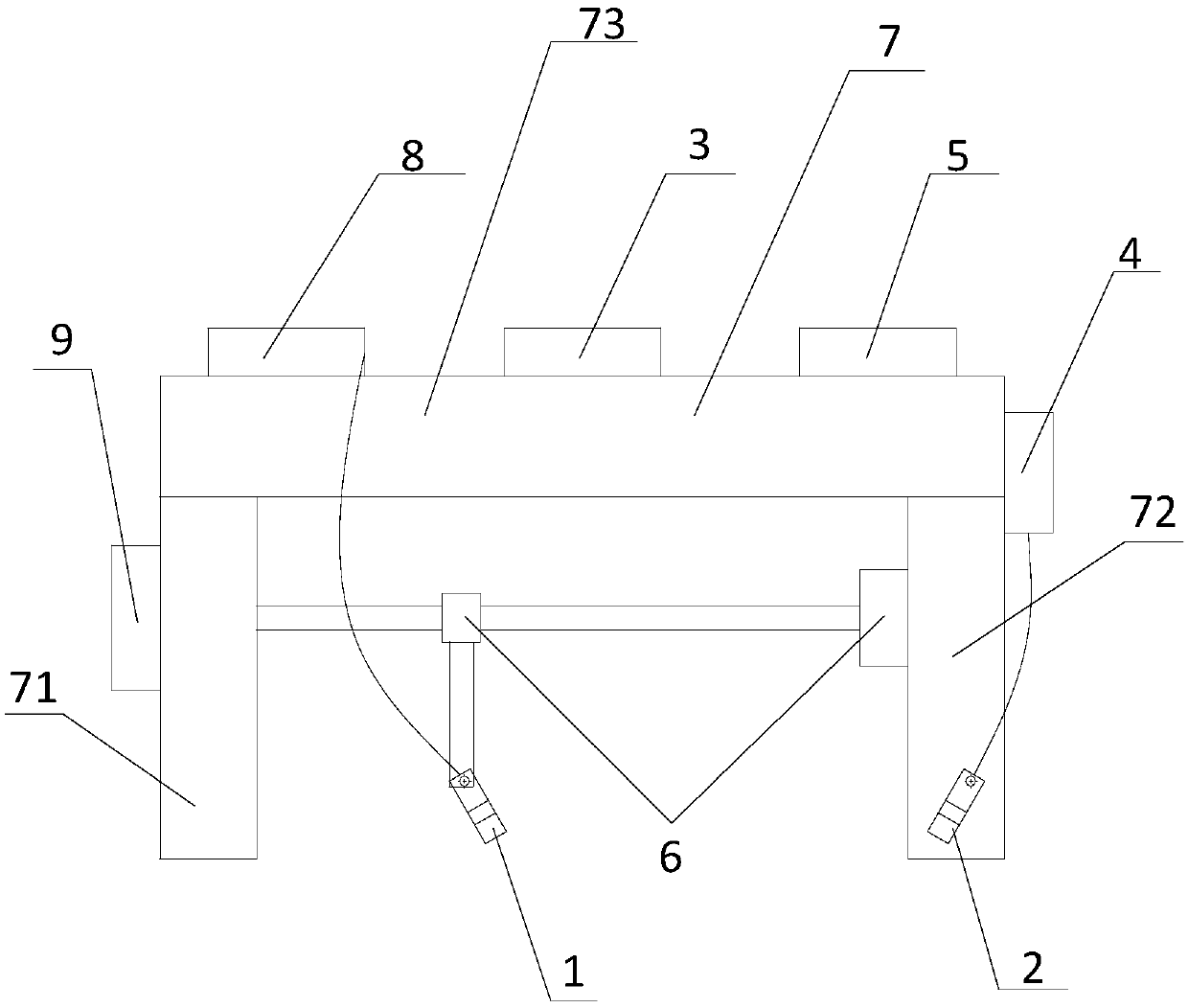

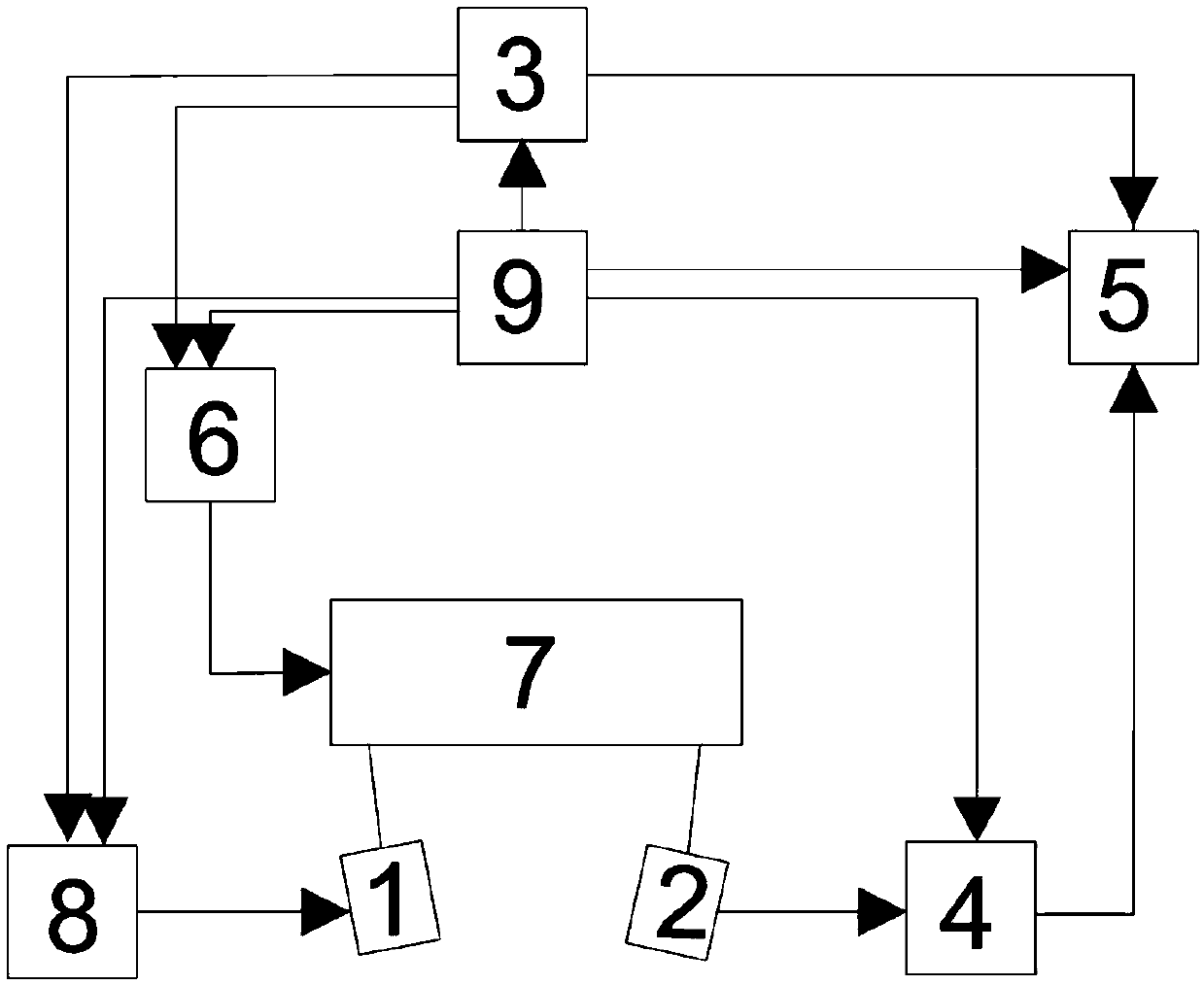

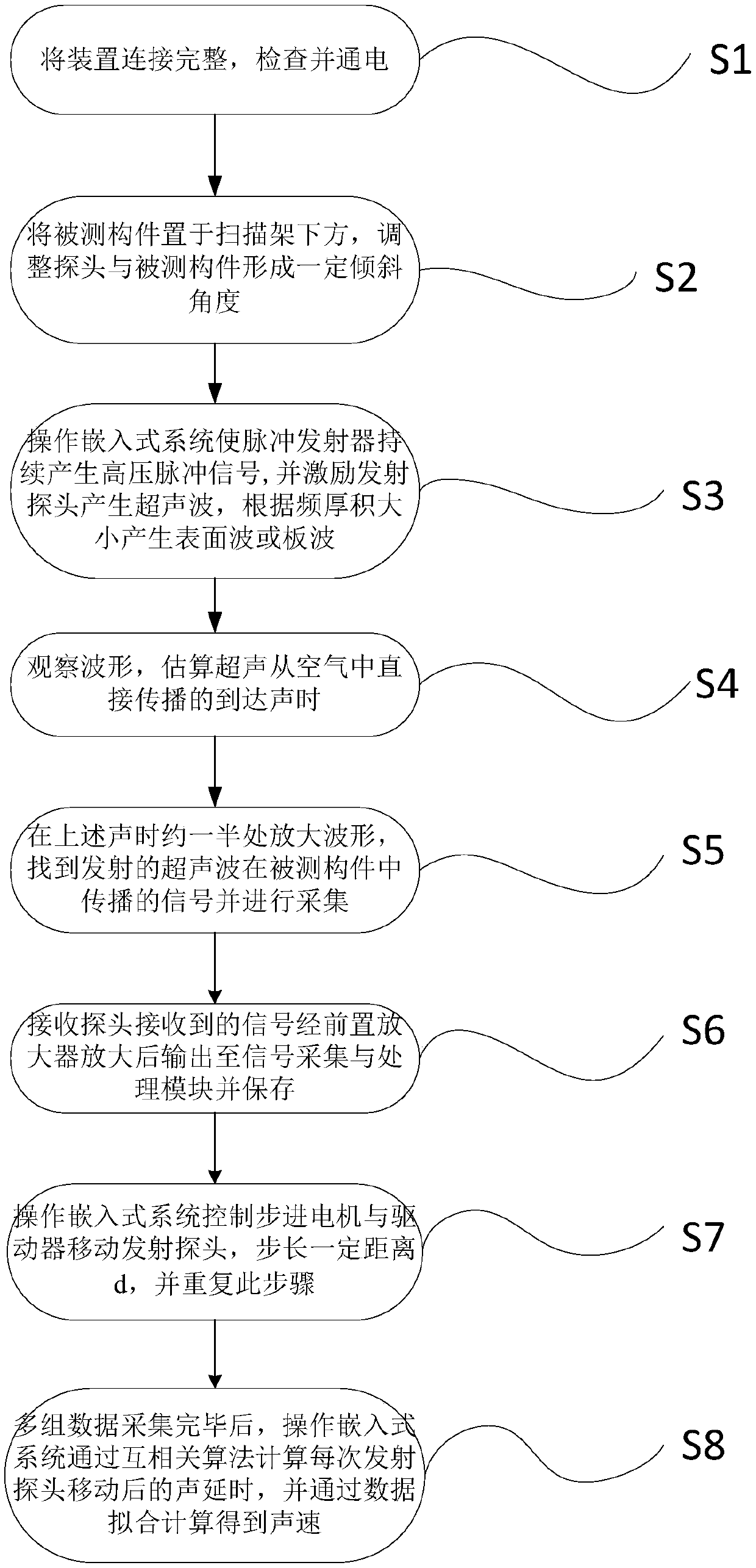

[0067] The device and method are used to detect the A0 mode plate wave velocity of an 8mm aluminum plate. The specific detection process is:

[0068] 1) Completely connect the entire detection device through the data cable and power on;

[0069] 2) Place the measured component under the scanning frame 7, and adjust the 50kHz probe to form a certain inclination angle with the measured component to meet the critical angle of incidence. After experiments, when the frequency thickness product is 5MHz·mm, the S0 and A0 modal plates The wave velocity tends to be consistent and becomes a surface wave. In this embodiment, the frequency-thickness product is 0.4MHz·mm, the incident angle is 11.5°, and the A0 mode plate wave is generated;

[0070] 3) The staff operates the embedded system 3 to make the pulse transmitter 8 continuously generate high-voltage pulse signals, and stimulate the transmitting probe 1 to generate ultrasonic waves;

[0071] 4) Observe the waveform to determine t...

Embodiment 2

[0079] The device and method are used to detect the surface wave velocity of an aluminum block. The specific detection process is:

[0080] 1) Completely connect the entire detection device through the data cable and power on;

[0081] 2) Place the component under test under the scanning frame 7, and adjust the 50kHz probe to form a certain inclination angle with the component under test to meet the critical angle of incidence;

[0082] 3) The staff operates the embedded system 3 to make the pulse transmitter 8 continuously generate high-voltage pulse signals, and stimulate the transmitting probe 1 to generate ultrasonic waves;

[0083] 4) Observe the waveform to determine the arrival time of the ultrasonic wave propagating from the air;

[0084] 5) Amplify the waveform at about half of the above sound time, find and collect the signal of the transmitted ultrasonic wave propagating in the component under test;

[0085] 6) The signal received by the acceptance probe 2 is amp...

Embodiment 3

[0091] The device and method are used to detect the A0 mode plate wave velocity of a 12mm steel plate. The specific detection process is:

[0092] 1) Completely connect the entire detection device through the data cable and power on;

[0093] 2) Place the component under test under the scanning frame 7, and adjust the 50kHz probe to form a certain inclination angle with the component under test to meet the critical angle of incidence;

[0094] 3) The staff operates the embedded system 3 to make the pulse transmitter 8 continuously generate high-voltage pulse signals, and stimulate the transmitting probe 1 to generate ultrasonic waves;

[0095] 4) Observe the waveform to determine the arrival time of the ultrasonic wave propagating from the air;

[0096] 5) Amplify the waveform at about half of the above sound time, find and collect the signal of the transmitted ultrasonic wave propagating in the component under test;

[0097] 6) The signal received by the receiving probe 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com