Low-silver back electrode slurry for chip resistors and preparation method for low-silver back electrode slurry

A technology of silver back electrode and slurry, which is applied in the manufacture of resistors, conductive materials dispersed in non-conductive inorganic materials, cables/conductors, etc., can solve the problems of high production costs, achieve no overflow, good continuity, The effect of good printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of low-silver back electrode paste for chip resistors, comprising the following steps:

[0032] Step 1: Preliminarily mix the silver powder, metal oxide, glass powder, modifier, and part of the organic carrier through a mixer, and then homogenize the initial mixture through a three-roll mill until all the powders are well dispersed to make a slurry semi-finished products;

[0033] Step 2: the semi-finished slurry obtained in step 1 and the remaining organic carrier are stirred for a second time by a mixer; then the paste after the second stirring is subjected to low-pressure rolling by a three-roll mill to make it fully dispersed;

[0034] Step 3: Aging of the slurry to improve the consistency of the slurry performance: the slurry is stored under stirring for 60-120 hours at a temperature of 40-60 °C, and after the temperature is lowered to room temperature, it is then sieved through a 250-mesh sieve and vacuumized. Defoaming is made into finished ...

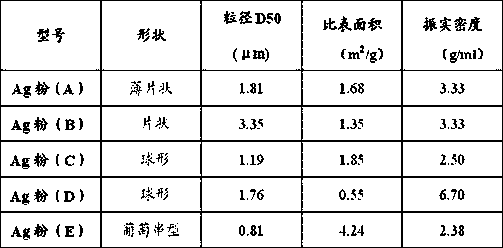

example 1

[0053] Step 1: 40 parts by mass of Ag powder (E), 3 parts by mass of nickelous oxide, 7 parts by mass of glass powder (including 5 parts by mass of glass powder 1 and 2 parts by mass of glass powder 2), 1 part by mass of DISPARLON, 19 parts by mass of glass powder Mass parts of the organic carrier are preliminarily mixed by a mixer, and then the initial mixture is homogenized by a three-roll mill until all the powders are well dispersed, and a semi-finished slurry is prepared;

[0054] Step 2: The semi-finished slurry obtained in step 1 and the remaining 30 parts by mass of the organic carrier are subjected to secondary stirring by a mixer, and then the paste after secondary stirring is subjected to low-pressure rolling by a three-roll mill to make it fully dispersed;

[0055] Step 3: The slurry was stirred and stored for 96 hours at 40°C, and after the temperature was lowered to room temperature, it was sieved through a 250-mesh sieve and vacuum defoamed to prepare Example Sam...

example 2

[0057] Step 1: 40 parts by mass of Ag powder (20 parts by mass of Ag powder (B), 20 parts by mass of Ag powder (E)), 3 parts by mass of nickelous oxide, and 7 parts by mass of glass powder (including 5 parts by mass of glass powder 1 and 2 parts by mass of glass frit 2), 1 part by mass of DISPARLON, and 19 parts by mass of organic carrier are preliminarily mixed by a mixer, and then, the initial mixture is homogenized by a three-roll mill until all powders are well dispersed to make a slurry semi-finished products;

[0058] Step 2: The semi-finished slurry obtained in step 1 and the remaining 30 parts by mass of the organic carrier are subjected to secondary stirring by a mixer, and then the paste after secondary stirring is subjected to low-pressure rolling by a three-roll mill to make it fully dispersed;

[0059] Step 3: The slurry was stored under stirring for 96 hours at 40°C, and after the temperature was lowered to room temperature, it was sieved through a 250-mesh sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com