OLED structure, preparation method thereof, display panel and electronic device

An electrode and electrical connection technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problem of poor display effect on the display screen, achieve excellent display performance, reduce the probability of bulging or cracking, and ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It can be seen from the background art that the display screen in the prior art has the problem of poor display effect.

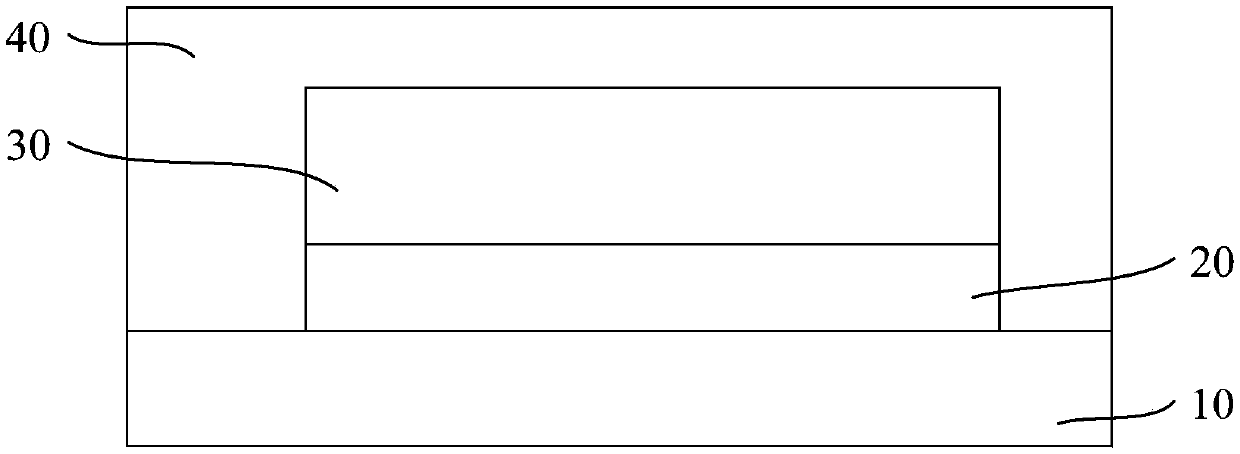

[0027] refer to figure 1 , figure 1 It is a schematic diagram of a partial cross-sectional structure of an existing OLED display screen, and the OLED display screen includes: a thin film transistor (TFT, Thin Film Transistor) 10; a multilayer structure 20 located on the thin film transistor 10, the multilayer structure 20 includes an anode layer and An organic functional layer on the surface of the anode layer; a cathode layer 30 on the surface of the multilayer structure 20; an encapsulation layer 40 covering the cathode layer 30, the surface of the TFT 10 and the sidewall of the multilayer structure 20.

[0028] The inventors have found that during the dynamic bending process of the OLED display, the film layer is easily damaged in the bending area, which will lead to poor display effect or even display failure. The main reason is that the thin f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com