Rapid feeding device of 3D printer

A technology of 3D printer and feeding device, which is applied in the direction of 3D object support structure, liquid material additive processing, additive manufacturing, etc. It can solve the problems of poor mixing effect of liquid raw materials and achieve the effect of accelerating feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is a further detailed description through specific implementations:

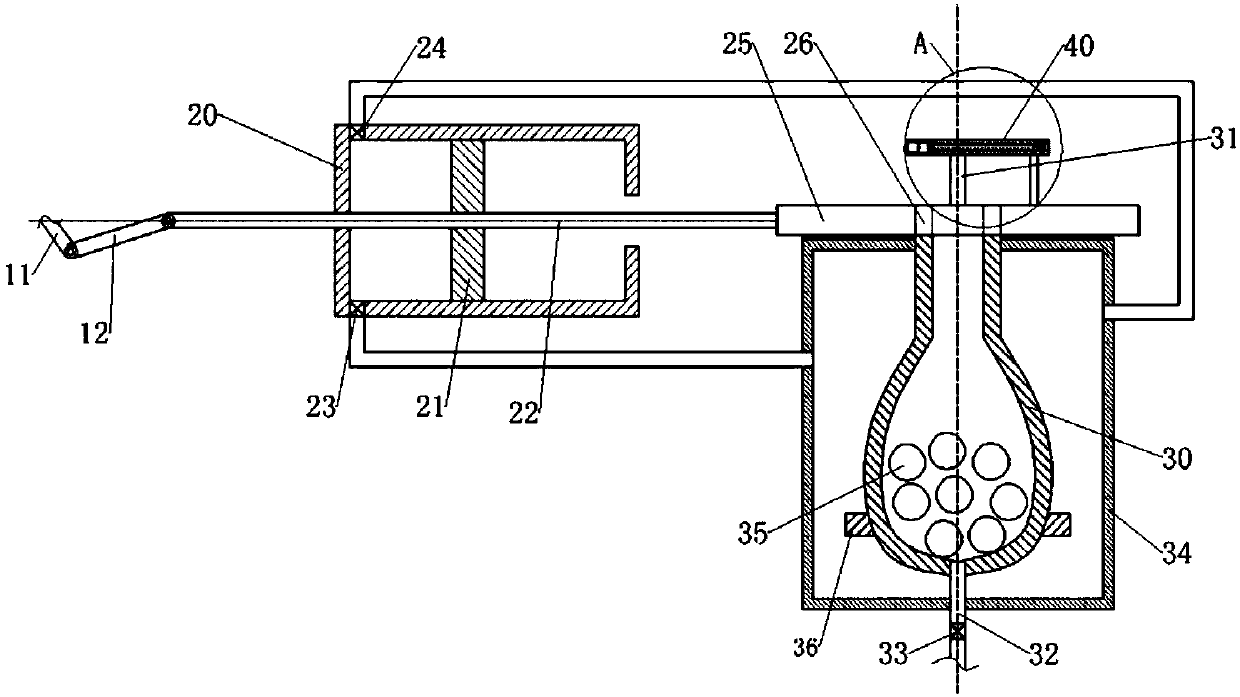

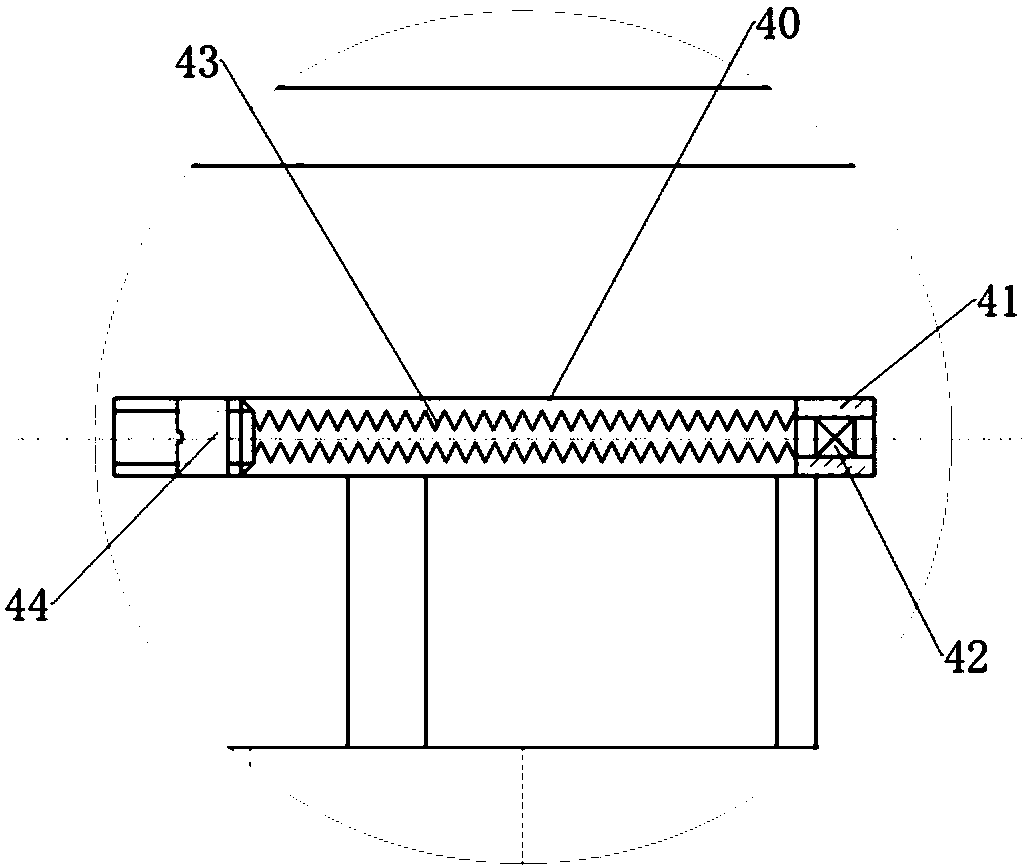

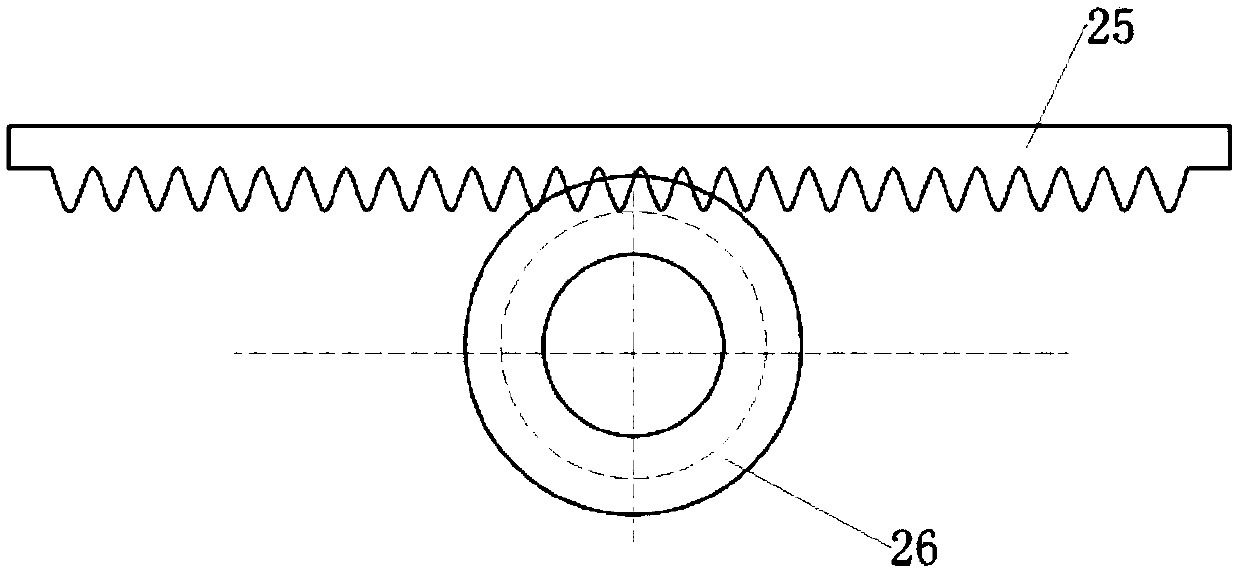

[0027] The reference signs in the drawings of the specification include: crank 11, connecting rod 12, piston cylinder 20, piston 21, piston rod 22, one-way air inlet valve 23, one-way air outlet valve 24, rack 25, gear 26, drop type Balloon 30, drop-shaped balloon inlet 31, drop-shaped balloon outlet 32, control valve 33, box 34, stirring beads 35, centrifugal block 36, feed tube 40, plunger 41, one-way valve 42, spring 43 , End cap 44.

[0028] Such as figure 1 As shown, a fast feeding device for a 3D printer includes a motor, a frame, and a drop-shaped balloon 30. The drop-shaped balloon 30 is made of rubber material so that the drop-shaped balloon 30 can be contracted, and the motor is fixedly connected to the frame. The upper end of the drop-shaped balloon 30 is provided with a drop-shaped balloon inlet 31, the lower end of the drop-shaped balloon is provided with a drop-shaped balloon o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com