Wood fiber seat and production technology thereof

A production process and wood fiber technology, applied in vehicle seats, special positions of vehicles, transportation and packaging, etc., can solve problems such as environmental protection, and achieve the effects of easy storage, easy operation of production process, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

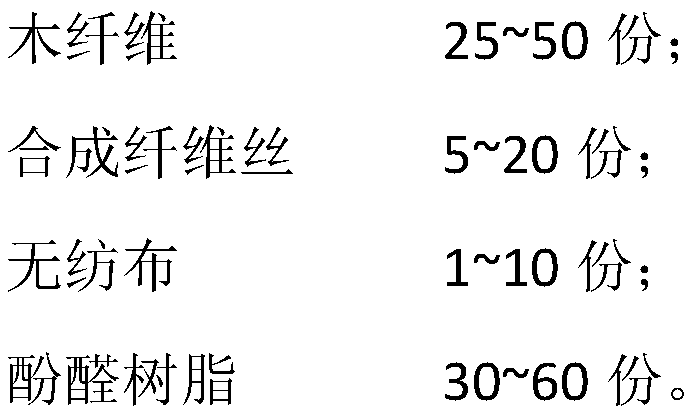

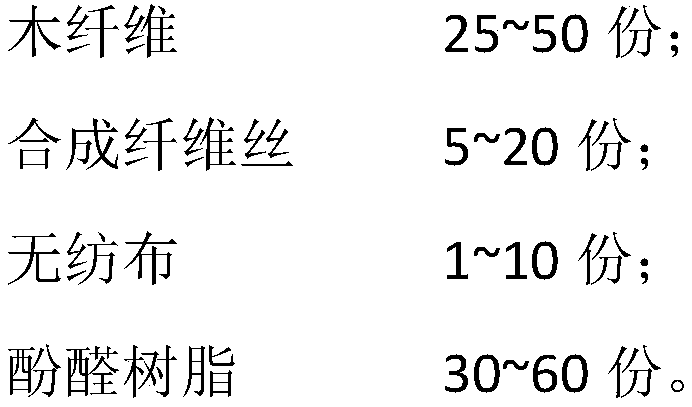

[0029] The raw material ratio of wood fiber seat in the present embodiment is that the weight ratio of wood fiber, synthetic fiber silk, non-woven fabric, phenolic resin is 35:10:5:50, and the phenolic resin here is that phenolic resin accounts for in the final product The specific gravity, the length of the wood fiber filament is selected as 10mm, and the length of the composite fiber filament is selected as the PET fiber filament of 100mm.

[0030] The production technology of wood fiber seat in the present embodiment, comprises the steps:

[0031] 1) Weighing: Weigh the raw materials according to the weight ratio of wood fiber, synthetic fiber silk and non-woven fabric as 35:10:5;

[0032] 2) Weaving felt: wood fiber, synthetic fiber yarn and non-woven fabric are woven into a certain specification of wood fiber felt through knitting equipment; the certain specification is determined according to the size requirements of the final seat. The size of the wood fiber felt is 1m...

Embodiment 2

[0041] The raw material ratio of wood fiber seat in the present embodiment is that the weight ratio of wood fiber, composite fiber silk, non-woven fabric, phenolic resin is 40:10:5:45, and the phenolic resin here is that phenolic resin accounts for in the final product The specific gravity, the length of the wood fiber filament is selected as 20mm, and the composite fiber filament is selected as the PET fiber filament with a length of 100mm.

[0042] The production technology of wood fiber seat in the present embodiment, comprises the steps:

[0043] 1) Weighing: Weigh the raw materials according to the weight ratio of wood fiber, synthetic fiber silk and non-woven fabric as 40:10:5;

[0044] 2) Weaving felt: wood fiber, synthetic fiber yarn and non-woven fabric are woven into a certain specification of wood fiber felt through knitting equipment; the certain specification is determined according to the size requirements of the final seat. The size of the wood fiber felt is 1....

Embodiment 3

[0053] The raw material ratio of wood fiber seat in the present embodiment is that the weight ratio of wood fiber, composite fiber silk, non-woven fabric, phenolic resin is 45:15:5:35, and the phenolic resin here is that phenolic resin accounts for in the final product The specific gravity, the length of the wood fiber filament is selected as 5mm, and the composite fiber filament is selected as a PET fiber filament with a length of 250mm.

[0054] The production technology of wood fiber seat in the present embodiment, comprises the steps:

[0055] 1) Weighing: Weighing raw materials according to the weight ratio of wood fiber, synthetic fiber silk and non-woven fabric is 45:15:5;

[0056] 2) Weaving felt: wood fiber, synthetic fiber yarn and non-woven fabric are woven into a certain specification of wood fiber felt through knitting equipment; the certain specification is determined according to the size requirements of the final seat. The size of the wood fiber felt is 1m*1m*...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com