Method and device for on-line rapid sulfur extraction and rapid heating of catalyst

A catalyst and fast technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems of long heating time of the catalyst bed, slow heating rate of the catalyst bed, and long driving time, etc., and meet the requirements of safety and environmental protection. , Increase the speed and effect of sulfur extraction, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of method of on-line rapid sulfur extraction and catalyst heating of the present invention comprises the following steps:

[0022] (1) Before the start-up of the low-temperature methanol washing device, if there is no fuel gas in the front system or the combustible gas content in the fuel gas is too low to be combustible, close the fuel gas shut-off valve C6, open the fuel gas shut-off valve A4, fuel gas shut-off valve B5, The gas valve 7 is used to ignite and burn the main combustion furnace 12 to heat up, close the acid gas shut-off valve A1, open the nitrogen valve 2, the acid gas shut-off valve B3, increase the amount of nitrogen gas entering the main combustion furnace 12, control the heating rate, and use a large amount of gas at the same time The nitrogen gas is used to raise the temperature of the catalyst bed of the sulfur recovery unit 13, and finally after the low-temperature methanol washing unit starts to produce acid gas, the sulfur recovery unit 13 ...

Embodiment 2

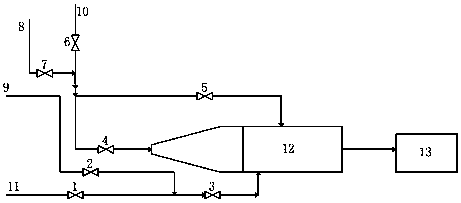

[0026] A sulfur recovery device for online rapid sulfur extraction and catalyst heating of the present invention comprises a main fuel gas pipeline 10, an acid gas pipeline 11, a main combustion furnace 12, a sulfur recovery device 13, and the main fuel gas pipeline 10 and acid gas pipeline 11 respectively It is connected with the main combustion furnace 12, and the outlet pipe of the main combustion furnace 12 is connected with the sulfur recovery device 13, wherein: the acid gas shut-off valve A1 and the acid gas shut-off valve B3 on the acid gas pipeline 11 entering the main combustion furnace 12 are provided with a nitrogen gas pipeline 9 ; The main fuel gas pipeline 10 is provided with a gas pipeline 8, and the main fuel gas pipeline 10 is divided into two groups and connected with the main combustion furnace body and the head respectively, and the two groups of fuel gas pipelines are respectively provided with a fuel gas shut-off valve A4, a fuel gas Stop valve B5, a gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com