Technology for pre-treating coal chemical wastewater through acidizing-compound flocculation process

A technology for coal chemical wastewater and chemical wastewater, which is used in flocculation/sedimentation water/sewage treatment, filtration treatment, sedimentation treatment, etc., can solve the problems of large investment, complex process flow, poor effect, etc., and achieves low investment and simple process flow. Reliable and economical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

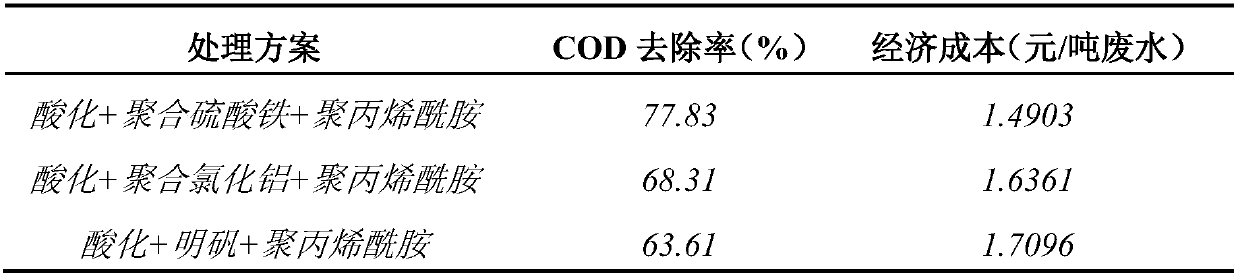

[0017] Take the coal chemical wastewater after acidification pretreatment, adjust its pH value with sodium hydroxide solution, then add a certain amount of polyferric sulfate solution, polyaluminum chloride solution and alum solution with a mass fraction of 5%, and stir rapidly for 1 min first, Then stir slowly for 10 minutes, then let it stand for precipitation for 30 minutes, and take the supernatant to detect the COD removal rate. The results show that the optimum pH values of polyferric sulfate solution, polyaluminum chloride solution and alum solution are 8, 7, and 7, respectively. .

Embodiment 2

[0019] Use sodium hydroxide solution to adjust the pH value to the optimum pH value of various flocculants, add different amounts of flocculants to the wastewater according to the reasonable dosage of various flocculants from 20% to 120%, and stir quickly first 1min, then slowly stirred for 10min, and then allowed to settle for 30min, then took the wastewater supernatant to measure its COD, and calculated the COD removal rate. The results showed that the optimum dosages of polyferric sulfate, polyaluminum chloride and alum were 1.0g / L, 0.8g / L and 0.8g / L, respectively.

Embodiment 3

[0021] Take the coal chemical wastewater after acidification pretreatment, fix the dosage of polyferric sulfate at 1.0g / L, then use sodium hydroxide solution to adjust the pH value of the wastewater to the pH value of flocculant polyferric sulfate at 8, and then add different A large amount of polyacrylamide, first stirred rapidly for 1min, then stirred slowly for 10min, then allowed to settle for 30min, took the supernatant to measure its COD, measured its COD, and investigated the influence of polyacrylamide dosage on the COD removal rate, The results showed that the optimum dosage of coagulant polyacrylamide in composite flocculation was 0.02g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com