Metal ceramic anilox roller and manufacturing method thereof

A metal-ceramic and metal-ceramic coating technology, applied in the direction of metal material coating process, coating, printing, etc., can solve the problems of uncontrollability, large limitations, reducing the competitiveness of ceramic anilox roll products, etc., and achieve high toughness. and wear resistance, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a cermet anilox roll, comprising:

[0033] A sufficiently thick cermet coating is prepared on the hollow metal roller surface by supersonic flame spraying method;

[0034] Mechanical grinding and precision polishing of the cermet coating to obtain a ceramic roller workpiece;

[0035] Using a pulsed solid-state laser, the depth of the mesh is adjusted by changing the laser energy and repeatedly striking, and engraving a uniform mesh structure on the surface of the ceramic roller workpiece;

[0036] Polish and clean the mesh structure.

[0037] In detail, cermets are widely used because they contain metal components (mainly Co, Ni, NiCr, etc.), which have higher toughness, lower coefficient of friction and higher wear resistance than oxide ceramics, and are widely used. It is widely used in cutting tools, drawing dies, punching dies, boilers and nuclear reactor materials, especially ceramic alloys based on WC and cobalt as a binder have good wear ...

Embodiment 1

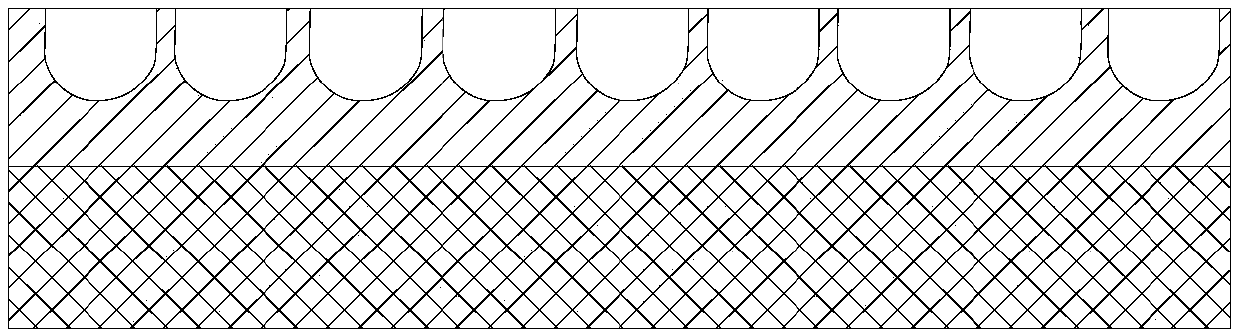

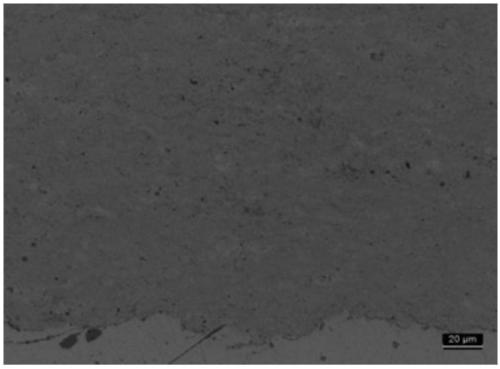

[0053] Weigh 5000 grams of WC-14Co powder, add it to the powder feeder, and use the supersonic flame spraying process to spray a coating with a thickness of 0.3mm. After processing to 0.2mm, select a 1.5-inch focusing lens with a focal length of 30mm to engrave a 1000lpi quadrilateral mesh. The cross-section and surface schematic diagram of the mesh structure are shown in figure 1 as well as figure 2 as shown, figure 1 The upper part is a cermet coating with a mesh structure, and the lower part is a metal body. The microstructure and quadrilateral mesh structure of laser engraved WC-14Co such as image 3 and Figure 4 shown.

Embodiment 2

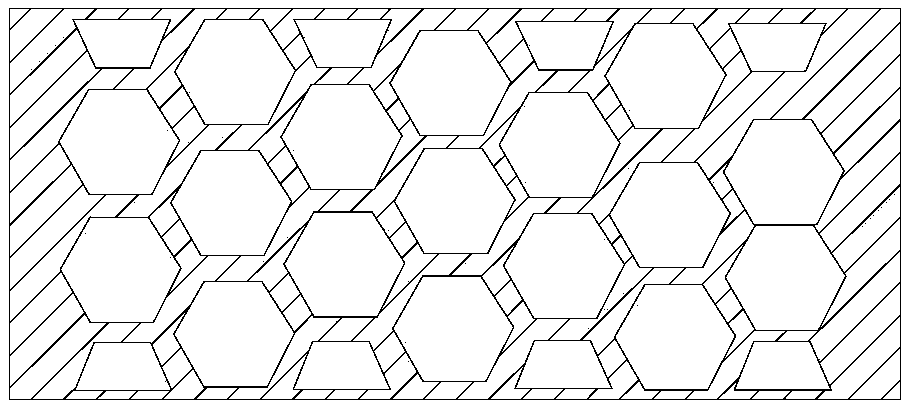

[0055] Weigh 5000 grams of WC-10Co4Cr powder, add it to the powder feeder, and use the supersonic flame spraying process to spray the coating with a thickness of 0.4mm. Hexagonal mesh. The microstructure and hexagonal mesh structure of its laser-engraved WC-10Co4Cr such as Figure 5 and Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com