Method for detecting boron element in ferromanganese alloy

A ferromanganese alloy and detection method technology, applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as difficult to meet production requirements, complex analysis process, cumbersome processing steps, etc., to achieve elimination of matrix effect, simple processing method, and less chemical reagents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

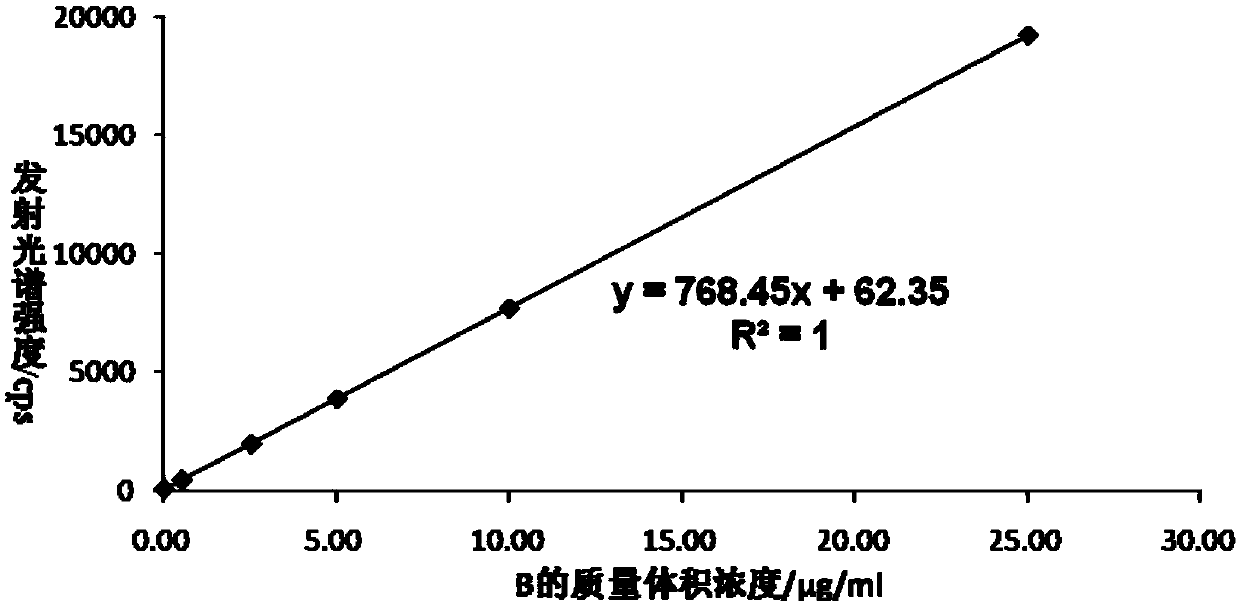

Examples

Embodiment 1

[0040] 1. Selection of equipment and working conditions

[0041] Instrument model: ICAP7400 full-spectrum direct-reading inductively coupled plasma emission spectrometer (Thermo Fisher Company, USA), among which, quartz atomizer and quartz atomization chamber are selected;

[0042] ICP-OES is CID detection, the integration method is one-point integration of peak height (inherent hardware of the instrument), considering factors such as the life of the rectangular tube, gas consumption, test stability, laboratory installation conditions, etc. The working parameters are: flushing pump speed: 50rpm; analysis pump speed: 50rpm; RF power is 1150W; auxiliary gas flow rate is 0.5L / min; vertical observation height: 12.0mm; atomizer gas flow rate is 0.55L / min; cooling gas The flow rate is 12L / min; the integration time is 15s in the ultraviolet region and 5s in the visible light region.

[0043] 2. Main reagents and standard solutions

[0044] In the present invention, the experimental...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com