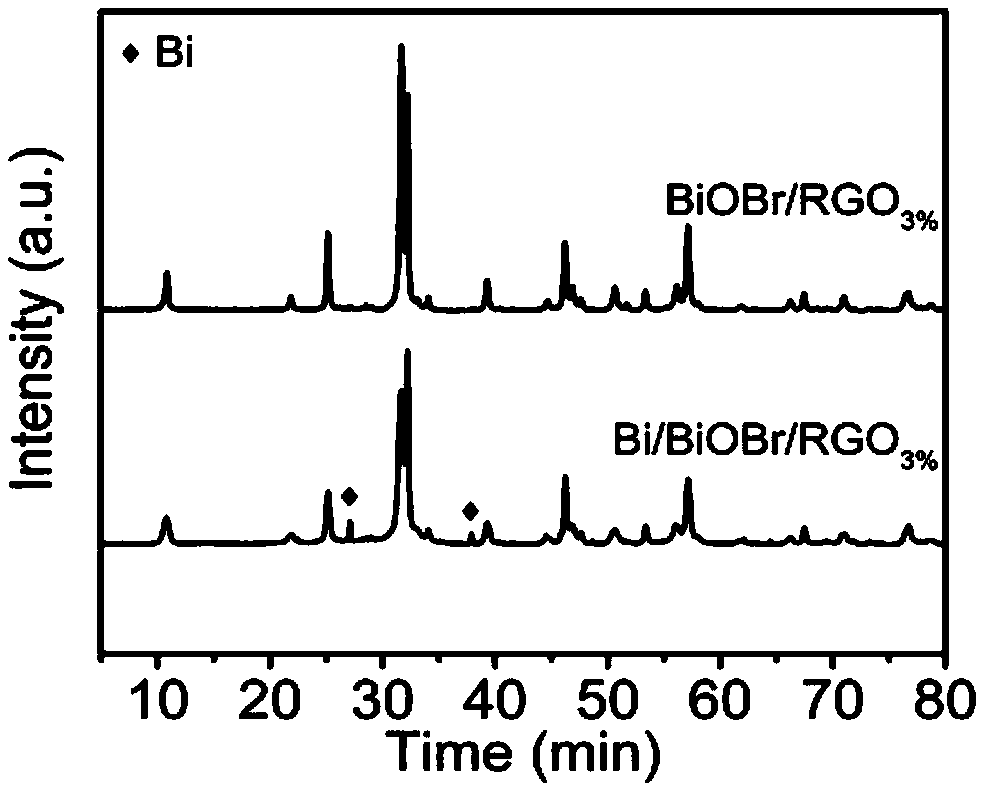

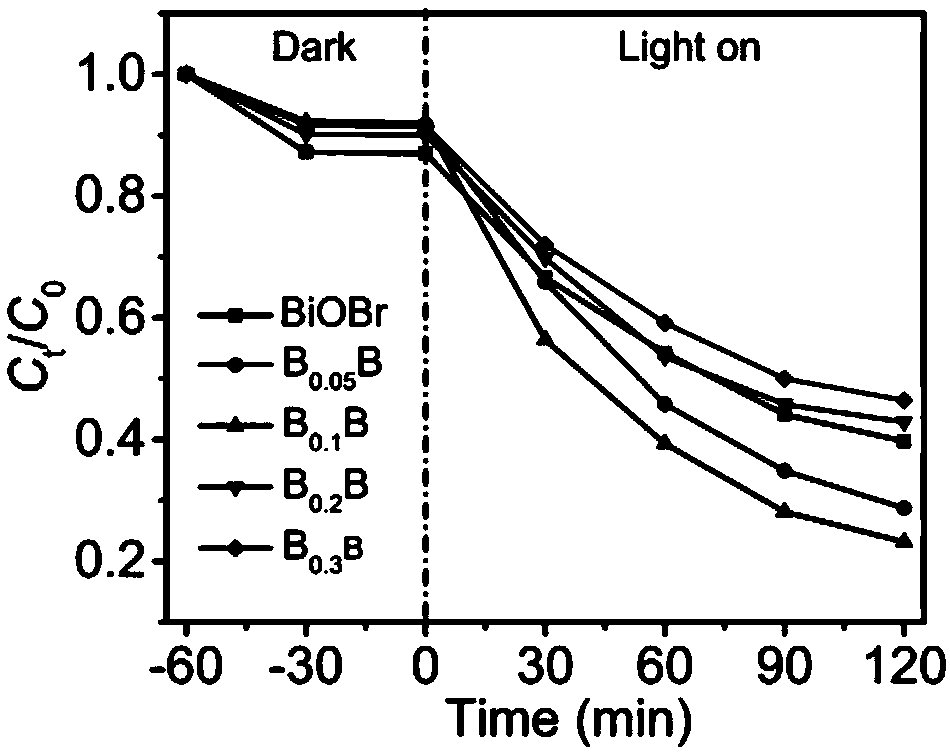

Preparation method, product and application of Bi/BiOBr/RGO composite photocatalyst

A catalyst and composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high cost of preparation methods, unfavorable large-scale production, complex processes, etc., and improve catalytic performance. , The effect of promoting multiple scattering and photocatalytic performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) dissolving the bismuth source in ethylene glycol solution to form a concentration of 0.0550mol / L bismuth salt solution;

[0037] (2) Potassium bromide is dissolved in distilled water and form concentration is 0.2mol / L potassium bromide solution;

[0038] (3) Potassium bromide solution is slowly added to the bismuth salt solution, in volume ratio, potassium bromide solution: bismuth salt solution is 1:4, continues to stir 15min, obtains potassium bromide bismuth salt mixed solution;

[0039] (4) Ultrasonic treatment of graphite oxide in distilled water, the ultrasonic power is 250W, the ultrasonic time is 30min, and the ultrasonic frequency is 40KHz, and the concentration is made into a graphene suspension of 10.3g / L;

[0040] (5) The graphene suspension of 10.3g / L is added in the potassium bromide bismuth salt mixed solution, wherein, in volume ratio, graphene oxide suspension: potassium bromide bismuth salt mixed solution is 3:5 ;Continue stirring for 30min and ca...

Embodiment 2

[0044] (1) dissolving the bismuth source in ethylene glycol solution to form a concentration of 0.0550mol / L bismuth salt solution;

[0045] (2) Potassium bromide is dissolved in distilled water and form concentration is 0.2mol / L potassium bromide solution;

[0046] (3) Potassium bromide solution is slowly added to the bismuth salt solution, in volume ratio, potassium bromide solution: bismuth salt solution is 1:4, continues to stir 30min, obtains potassium bromide bismuth salt mixed solution;

[0047] (4) Ultrasonic treatment of graphite oxide in distilled water, the ultrasonic power is 250W, the ultrasonic time is 30min, and the ultrasonic frequency is 40KHz, and the concentration is made into a graphene suspension of 31.3g / L;

[0048] (5) The graphene suspension of 31.3g / L is added in the potassium bromide bismuth salt mixed solution, wherein, in volume ratio, graphene oxide suspension: potassium bromide bismuth salt mixed solution is 3:5 ;Continue stirring for 60min and ca...

Embodiment 3

[0053] (1) dissolving the bismuth source in ethylene glycol solution to form a concentration of 0.0550mol / L bismuth salt solution;

[0054] (2) Potassium bromide is dissolved in distilled water and form concentration is 0.2mol / L potassium bromide solution;

[0055] (3) Potassium bromide solution is slowly added to the bismuth salt solution, in volume ratio, potassium bromide solution: bismuth salt solution is 1:4, continues to stir 30min, obtains potassium bromide bismuth salt mixed solution;

[0056] (4) Ultrasonic treatment of graphite oxide in distilled water, the ultrasonic power is 250W, the ultrasonic time is 30min, and the ultrasonic frequency is 40KHz, and the concentration is made into a graphene suspension of 53.0g / L;

[0057] (5) The graphene suspension of 53.0g / L is added in the potassium bromide bismuth salt mixed solution, wherein, in volume ratio, graphene oxide suspension: potassium bromide bismuth salt mixed solution is 3:5 ;Continue stirring for 60min and ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com