A kind of ultra-low thickness PE film and preparation method thereof

An ultra-low-density, thin-film technology, applied in the field of plastic films, can solve the problems of film strength, physical and chemical properties of barrier properties, increase of production costs and waste of energy, film processing is not smooth, etc., to achieve sensitivity to ambient temperature and humidity Low cost, easy operation, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The LLDPE in the modified ultra-low density LLDPE in the present invention is the same as the LLDPE in the outer layer. The preparation method of described modified ultra-low density LLDPE comprises the steps:

[0044] 1-10 parts by weight of maleic anhydride, 0.5-1% by weight of cumene peroxide, 1-2% of antioxidant and 100 parts of LLDPE plastic rice are blended through a high-speed mixing and stirring tank, and added to a twin-screw extruder. The modified ultra-low density LLDPE is obtained by melt grafting in the machine and sheared and granulated. The temperature settings of each section are as follows: Zone 1: 190-200°C, Zone 2: 210-220°C; Zone 3: 220-230°C, Zone 4: 220-230°C, Zone 5: 220-230°C, Zone 6: 220-230°C, head area: 190-200°C.

[0045] In some preferred embodiments, the raw materials for preparing the inner layer include LLDPE70-80, modified ultra-low density LLDPE 20-30, blocking agent 3-4, and PPA rheology agent 1-3 in parts by weight.

[0046] The LL...

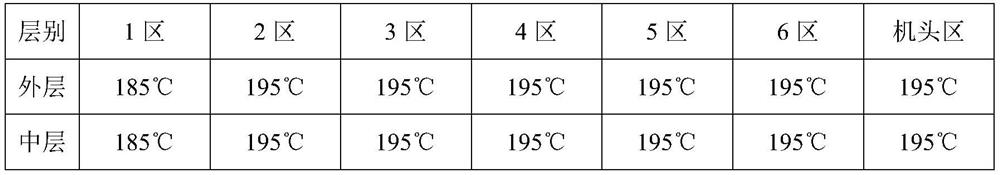

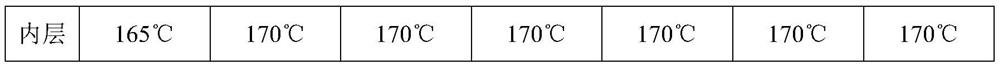

Embodiment 1

[0070] Embodiment 1 provides a kind of ultra-low thickness PE film, and described ultra-low thickness PE film is made up of outer layer, middle layer and inner layer, and its weight ratio is 30:25:30; The preparation raw material of described outer layer, with In parts by weight, it includes high-density polyethylene (HDPE) 70, linear low-density polyethylene (LLDPE) 10, opening agent 3, and PPA rheological agent 1; the raw materials for the preparation of the middle layer include HDPE 70, LLDPE 10, EVOH modified polypropylene 5, PPA rheological agent 1; the preparation raw materials of the inner layer, in parts by weight, include LLDPE 70, modified ultra-low density LLDPE 20, blocking agent 3, PPA rheological agent 1 .

[0071] Described HDPE is purchased from Lotte Chemical trade mark and is 8300B product (melt index is 0.02g / 10min; Density is 0.95g / cm 3 ); said LLDPE purchased from Canada NOVA brand is GX-4010P product (melt index is 0.2g / 10min; density is 0.918g / cm 3 ); ...

Embodiment 2

[0082] Embodiment 2 provides a kind of ultra-low thickness PE film, and described ultra-low thickness PE film is made up of outer layer, middle layer and inner layer, and its weight ratio is 40:35:40; The preparation raw material of described outer layer, with In parts by weight, it includes high-density polyethylene (HDPE) 90, linear low-density polyethylene (LLDPE) 30, opening agent 5, and PPA rheology agent 2; the raw materials for the preparation of the middle layer include HDPE 90, LLDPE 30, EVOH modified polypropylene 15, PPA rheological agent 2; the preparation raw materials of the inner layer, in parts by weight, include LLDPE 80, modified ultra-low density LLDPE 30, blocking agent 4, PPA rheological agent 3 .

[0083] Described HDPE is purchased from Lotte Chemical trade mark and is 7700F product (melt index is 0.07g / 10min; Density is 0.955g / cm 3 ); said LLDPE purchased from Exxon Mobil is LL3105.50 product (melt index is 0.5g / 10min; density is 0.921g / cm 3 ); the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com