Preparation method for foam carbon

A carbon foam and carbon source technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of high production cost, large initial investment, unfavorable industrialization, etc., and achieve high compressive strength, safe raw materials, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

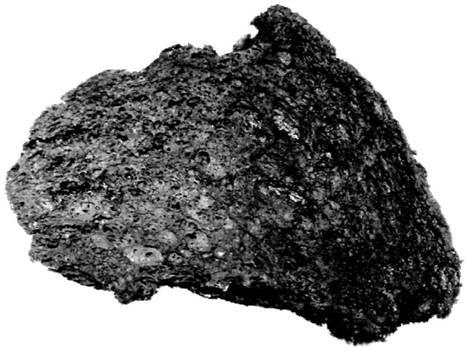

Image

Examples

Embodiment 1

[0038] Take 1000g of carbon source powder as an example.

[0039] (1) Put 450g of water in the container, add 10g of yeast, stir evenly, add 50g of sugar, stir to dissolve completely, under stirring conditions, slowly sprinkle 1000g of flour (100 mesh) into the container, after the flour is added, repeat the kneading , And finally make a uniform dough. Place the dough in a thermostat at 40±2°C for 1 hour and wait for the yeast to ferment.

[0040] (2) The fermented dough is pressed into a block as required, with a thickness of 5mm, placed in an oven at 105±2℃, and baked for 30 minutes to make the dough foam and shape.

[0041] (3) After the above foaming and shaping step is completed, the furnace temperature is continued to rise to 230°C for pretreatment, and the temperature is kept for 30 minutes to remove moisture and oxidize and remove easily oxidized elements.

[0042] (4) After the above pretreatment is completed, move the pretreated sample into a high-temperature furnace, and u...

Embodiment 2

[0044] Take 1000g of carbon source powder as an example.

[0045] (1) Put 500g of water in the container, add 5g of yeast, stir evenly, add 60g of sugar, add TiO 2 150g flour (model R248), stir and disperse evenly, and under stirring conditions, slowly sprinkle the mixture of 600g flour (100 mesh) and 400g (100 mesh) corn flour into it. After the addition is complete, knead repeatedly, and finally make Into a uniform dough. Place the dough in a thermostat at 40±2°C for 1 hour and wait for the yeast to ferment. Take 30g of water and add 5g of NaHCO 3 After the dissolution is complete, the NaHCO 3 Add the solution to the dough and knead again to make the whole dough even, and let it stand for 20 minutes to complete the dough preparation.

[0046] (2) The fermented dough is pressed into 20×20×10mm as required, put in an oven at 105±2℃, and baked for 35min to make the dough foam and shape.

[0047] (3) After the above foaming and shaping step is completed, the furnace temperature is co...

Embodiment 3

[0050] Take 1000g of carbon source powder as an example.

[0051] (1) Put 550g of water in the container, add 10g of yeast, mix well, add 80g of white sugar, add 50g of carbon fiber with a length of 1-5mm, stir and disperse evenly, and under stirring conditions, add 500g of flour (80 mesh), 300g The uniformly mixed powder of corn flour (80 mesh) and 200 g of glutinous rice flour is slowly sprinkled in, and after the addition is completed, the kneading is repeated to form a uniform dough. Place the dough in a thermostat at 40±2°C for 1 hour and wait for the yeast to ferment.

[0052] (2) The fermented dough is pressed into a sheet with a thickness of 50mm as required, put in an oven at 100±2℃, and baked for 40min to make the dough foam and shape.

[0053] (3) After the above foaming and shaping step is completed, the furnace temperature is continued to rise to 250°C for pretreatment, and the temperature is kept for 25 minutes to remove water and oxidize and remove easily oxidizable e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com