Nano polyurethane epoxy anticorrosive terrace coating

A polyurethane epoxy and floor coating technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problems of not participating in the chemical reaction of the coating, changing the coating performance, poor coating stability, etc., and improving the mechanical properties. , Improve the use temperature, the effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

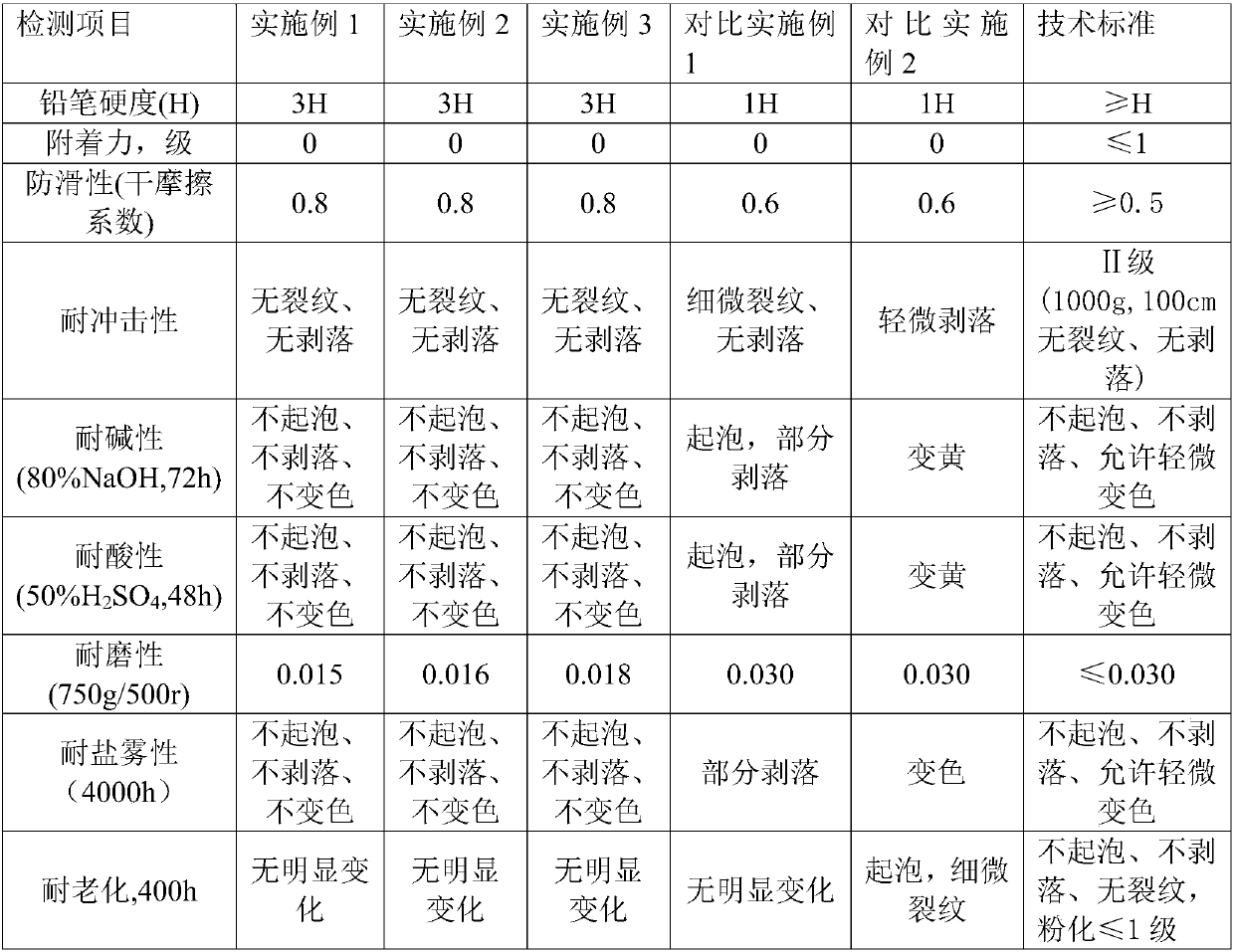

Examples

Embodiment 1

[0021] Nano-polyurethane epoxy anti-corrosion floor coating, said nano-polyurethane epoxy anti-corrosion floor includes component A and component B, and the component A and component B are formulated at a weight ratio of 6:1; The A component includes the following raw materials in parts by weight: 30 parts of 2,4-toluene diisocyanate, 30 parts of 1,6-hexamethylene diisocyanate, 40 parts of nano-polyoxypropylene triol, 20 parts of ethylene glycol ethyl ether acetate, 1 part of methyldiethanolamine, 10 parts of epoxy resin, 50 parts of filler, 1 part of color paste, 0.1 part of BYK-320, 0.1 part of BYK-052N, 0.1 part of BYK-1610.2 and 0.2 part of BYK-R605; the B component It includes the following raw materials in parts by weight: 40 parts of hydroxyl-containing silicone resin, 10 parts of polyether, and 1 part of dibutyltin diacetate.

[0022] Further, the filler includes mica powder, quartz powder and talc powder, wherein the components are respectively: 10 parts by weight of mic...

Embodiment 2

[0028] Nano-polyurethane epoxy anti-corrosion floor coating, said nano-polyurethane epoxy anti-corrosion floor includes component A and component B, and the component A and component B are formulated at a weight ratio of 6:1; Component A includes the following raw materials in parts by weight: 40 parts 2,4-toluene diisocyanate, 40 parts 1,6-hexamethylene diisocyanate, 45 parts nano-polyoxypropylene triol, 30 parts ethylene glycol ethyl ether acetate, 5 parts of methyldiethanolamine, 20 parts of epoxy resin, 75 parts of filler, 8 parts of color paste, 0.3 part of BYK-320, 0.5 part of BYK-052N, 0.5 part of BYK-1610.6 and 0.5 part of BYK-R605; the B component It includes the following raw materials in parts by weight: 50 parts of hydroxyl-containing silicone resin, 20 parts of polyether, and 5 parts of dibutyltin diacetate.

[0029] Further, the filler includes mica powder, quartz powder and talc powder, wherein the components are respectively 20 parts by weight of mica powder, 20 p...

Embodiment 3

[0035] Nano-polyurethane epoxy anti-corrosion floor coating, said nano-polyurethane epoxy anti-corrosion floor includes component A and component B, and the component A and component B are formulated at a weight ratio of 6:1; The A component includes the following raw materials in parts by weight: 35 parts of 2,4-toluene diisocyanate, 35 parts of 1,6-hexamethylene diisocyanate, 43 parts of nano-polyoxypropylene triol, 25 parts of ethylene glycol ethyl ether acetate, 4 parts of methyldiethanolamine, 18 parts of epoxy resin, 60 parts of filler, 6 parts of color paste, 0.2 part of BYK-320, 0.3 part of BYK-052N, 0.4 part of BYK-1610.4 and 0.4 part of BYK-R605; the B component It includes the following raw materials in parts by weight: 45 parts of hydroxyl-containing silicone resin, 15 parts of polyether and 3 parts of dibutyltin diacetate.

[0036] Further, the filler includes mica powder, quartz powder and talc powder, wherein the components are respectively 14 parts by weight of mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com