Method for constructing tissue engineering corneal limbus based on electrospinning mixed fiber membranes

An electrospinning process and hybrid fiber technology, which is applied in the field of tissue engineering limbus construction based on electrospinning hybrid fiber membranes, can solve the difficulty in regulating and controlling the Wiener structure of hydrogels, it is difficult to obtain a 3D structure, and it is difficult to perform fine regulation. and other problems, to achieve the effect of easy control, easy control and easy implementation of process conditions and mixed fiber membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

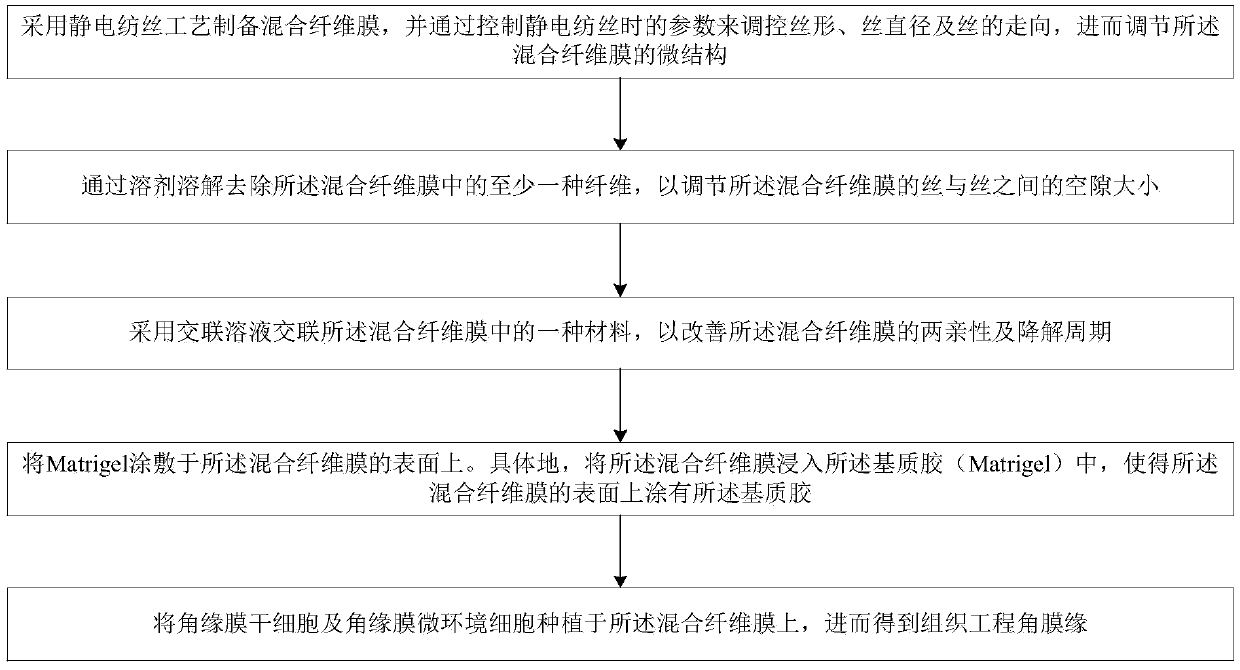

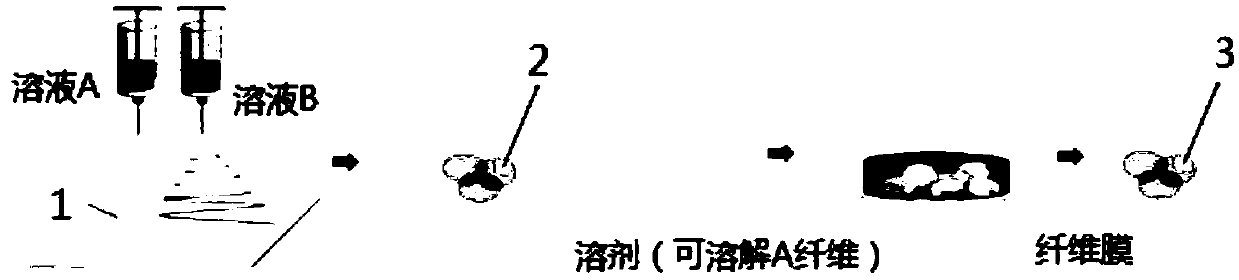

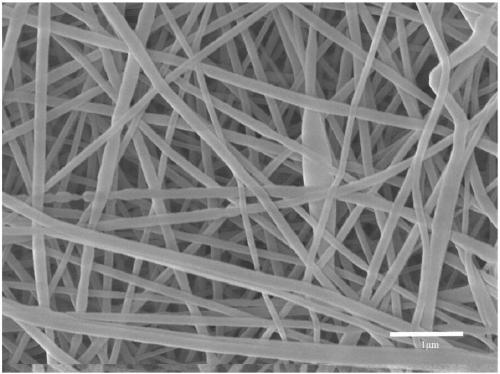

[0042] see Figure 4 , Figure 5A and Figure 5B According to the first embodiment of the present invention, the method for constructing tissue engineering corneal limbus based on electrospinning mixed fiber membrane mainly includes the following steps:

[0043] (1) Take a certain mass of polycaprolactone (PCL) / gelatin (gelatin), dissolve PCL and gelatin in a certain volume of trifluoroethanol (TFE) and glacial acetic acid, and stir overnight on a magnetic stirrer A PCL / gelatin mixed solution was obtained. Preferably, the mass ratio of the PCL and the gelatin is 8:2.

[0044] (2) The mixed solution obtained in step (1) is packed into a syringe with a volume of 10ml, the front end of the syringe is equipped with a 19G needle, the receiving end of the electrospinning machine is covered with 33cm*34cm tin foil, and the distance between the positive and negative electrodes is 18cm. The injection speed is 0.5ml / h, the high voltage power supply is turned on, and the positive and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com