Filament for cord thread and preparation method thereof

A technology for cords and filaments, which is applied in the field of filaments for cords and its preparation, can solve the problems of difficult rubber dipping and poor rubber adhesion, and achieve low adhesion, strong rubber adhesion, and reduced The effect of the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

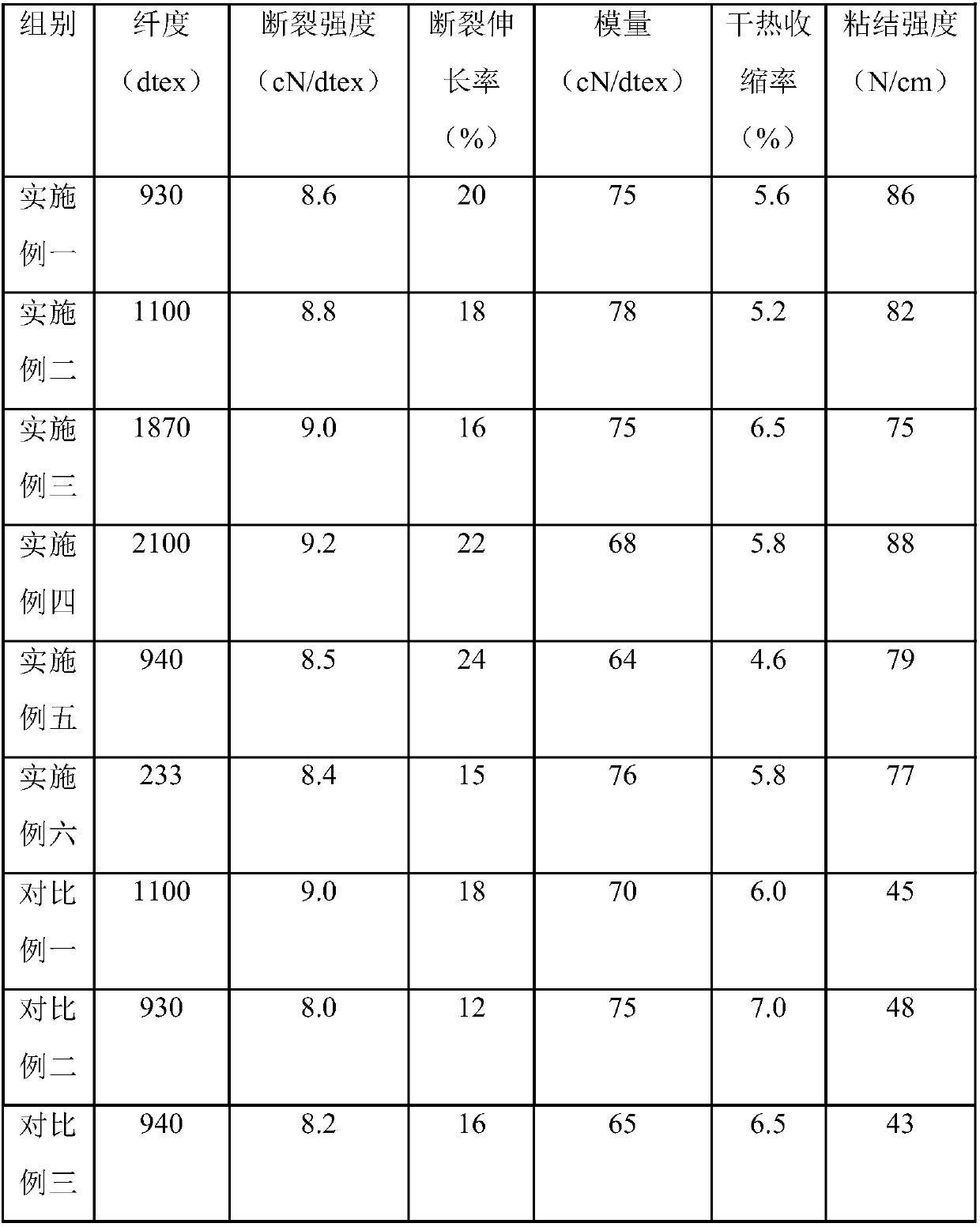

Examples

Embodiment 1

[0091] (1) Dry the polyethylene terephthalate resin in a continuous hot air drying tower, the drying temperature is 160°C, the drying time is 20h, and then heated to a molten state to form polyethylene terephthalate Melt, as core material;

[0092] (2) Dry the polyamide 56 resin in a vacuum drum dryer, the drying temperature is 100°C, the drying time is 25 hours, and then heated to a molten state to form a polyamide 56 melt as a skin layer material;

[0093] (3), the polyamide 56 melt and the polyethylene terephthalate melt are merged in the composite spinning assembly through their respective melt pipes, and extruded through the skin-core composite spinneret to form as-spun filaments. The proportion of core components is accurately adjusted by a metering pump, the content of the skin layer is 20wt%, and the content of the core layer is 80wt%;

[0094] (4) Process the as-spun yarn to obtain the filament for cord.

[0095] The relative viscosity of polyamide 56 resin 96wt% su...

Embodiment 2

[0103] (1), drying polytrimethylene terephthalate resin in a continuous hot air drying tower, the drying temperature is 145 ° C, the drying time is 28h, and then heated to a molten state to form a polytrimethylene terephthalate melt, as core material;

[0104] (2) Dry the polyamide 510 resin in a vacuum drum dryer, the drying temperature is 95°C, the drying time is 25h, and then heated to a molten state to form a polyamide 510 melt as a skin layer material;

[0105] (3), the polyamide 510 melt and the polytrimethylene terephthalate melt are merged in the composite spinning assembly through their respective melt pipes, extruded through the skin-core composite spinneret to form as-spun filaments, and the skin-core assembly The proportion is accurately adjusted by the metering pump, the content of the skin layer is 40wt%, and the content of the core layer is 60wt%;

[0106] (4) Process the as-spun yarn to obtain the filament for cord.

[0107] The polyamide 510 resin has a relati...

Embodiment 3

[0115] (1) Dry the polyethylene terephthalate resin in a continuous hot air drying tower, the drying temperature is 130°C, the drying time is 30h, and then heated to a molten state to form polyethylene terephthalate Melt, as core material;

[0116] (2) Dry the polyamide 66 resin in a vacuum drum dryer at a drying temperature of 125°C and a drying time of 15 hours, and then heat it to a molten state to form a polyamide 66 melt as a skin layer material;

[0117] (3), the polyamide 66 melt and the polyethylene terephthalate melt are merged in the composite spinning assembly through their respective melt pipes, and are extruded through the skin-core composite spinneret to form as-spun filaments. The proportion of core components is accurately adjusted by a metering pump, the content of the skin layer is 50wt%, and the content of the core layer is 50wt%;

[0118] (4) Process the as-spun yarn to obtain the filament for cord.

[0119] The polyamide 66 resin has a relative viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com