Anti-ultraviolet anti-reflection film layer and application thereof

A technology of anti-ultraviolet and anti-reflection film, applied in optics, instruments, optical components, etc., can solve the problems of high cost of use, high reflectance of visible light, low transmittance of visible light, etc., and achieve the effect of convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

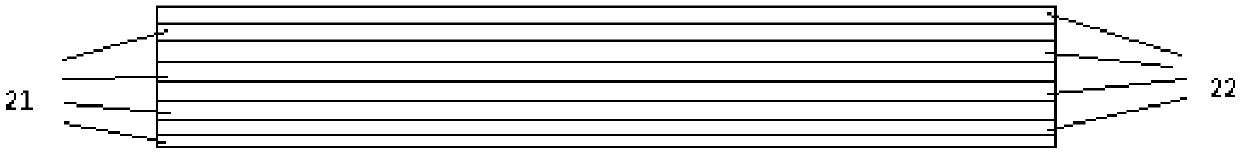

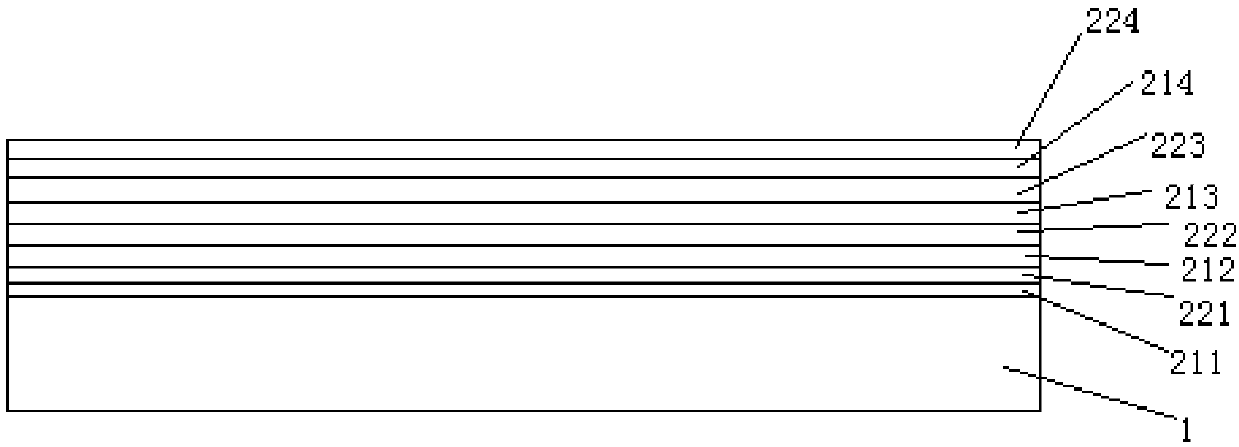

[0022] An anti-ultraviolet and anti-reflection film layer: composed of 8 layers of dielectric materials, from the inside to the outside, there are silicon nitride layer 211 with a thickness of 12.9nm, a silicon oxide layer 221 with a thickness of 64.7nm, and a silicon nitride layer 212 with a thickness of 24nm. A silicon oxide layer 222 with a thickness of 75nm, a silicon nitride layer 213 with a thickness of 20.3nm, a silicon oxide layer 223 with a thickness of 72nm, a silicon nitride layer 214 with a thickness of 24nm, and a silicon oxide layer 224 with a thickness of 117nm;

[0023] The above-mentioned anti-ultraviolet and anti-reflection film layer was coated on one side of the float glass with a thickness of 6 mm to obtain an anti-ultraviolet and anti-reflection glass.

Embodiment 2

[0025] An anti-ultraviolet and anti-reflection film layer: it is composed of 8 layers of dielectric materials, from the inside to the outside, there are niobium oxide layer with a thickness of 7nm, a silicon oxide layer with a thickness of 72.5nm, a silicon nitride layer with a thickness of 20nm, and an oxide layer with a thickness of 92.7nm. Silicon layer, a silicon nitride layer with a thickness of 24.7nm, a silicon oxide layer with a thickness of 79.6nm, a silicon nitride layer with a thickness of 25nm, and a silicon oxide layer with a thickness of 117nm;

[0026] The above-mentioned anti-ultraviolet and anti-reflection film layer is coated on both sides of the float glass with a thickness of 6 mm to obtain an anti-ultraviolet anti-reflection glass.

Embodiment 3

[0028] An anti-ultraviolet and anti-reflection film layer: composed of 8 layers of dielectric materials, from the inside to the outside are silicon nitride layer with a thickness of 18nm, silicon oxide layer with a thickness of 73.9nm, niobium oxide layer with a thickness of 23.6nm, and a thickness of 71.9nm A silicon oxide layer, a titanium oxide layer with a thickness of 18.7nm, a silicon oxynitride layer with a thickness of 75.6nm, a silicon nitride layer with a thickness of 30.7nm, and a silicon oxynitride layer with a thickness of 125.3nm;

[0029] The above-mentioned anti-ultraviolet and anti-reflection film layer was coated on one side of the float glass with a thickness of 6 mm to obtain an anti-ultraviolet and anti-reflection glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com