A dual-circular grinding system with ultrasonic assisted vaporization and cooling with fog cannon

An ultrasonic-assisted, fog cannon technology, which is applied in the direction of grinding drive devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of long grinding arc area, high grinding heat production, poor heat dissipation, etc. , to reduce environmental impact, improve heat dissipation efficiency, and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

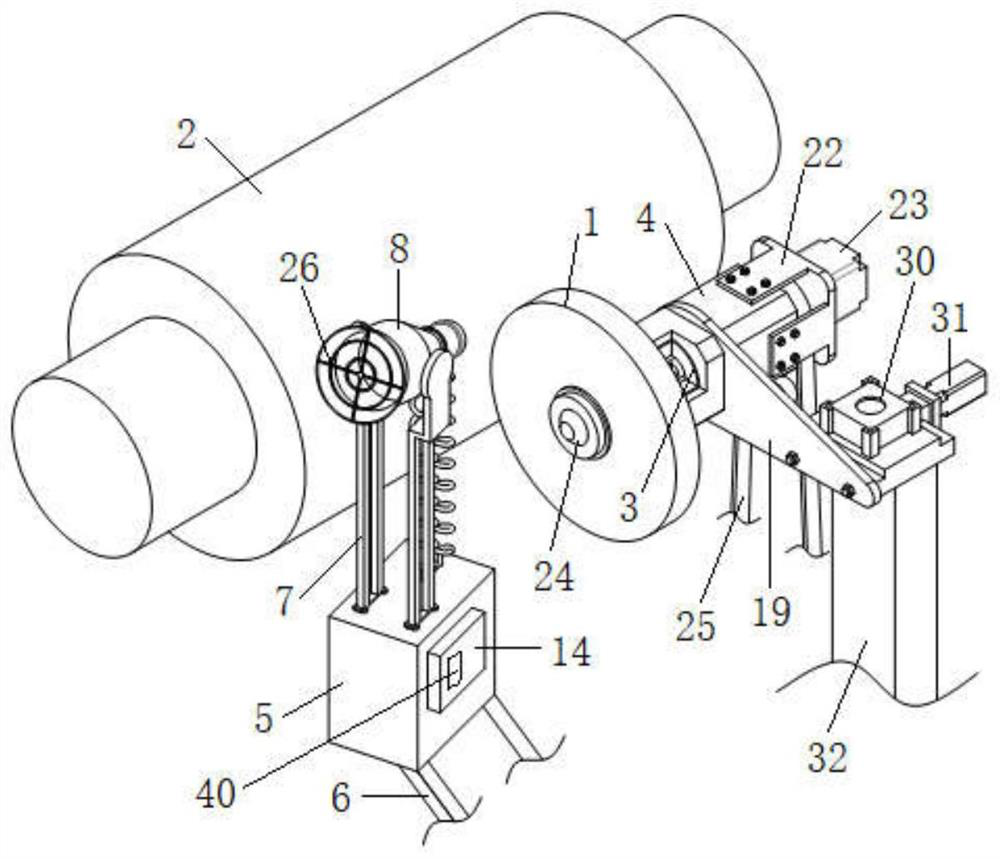

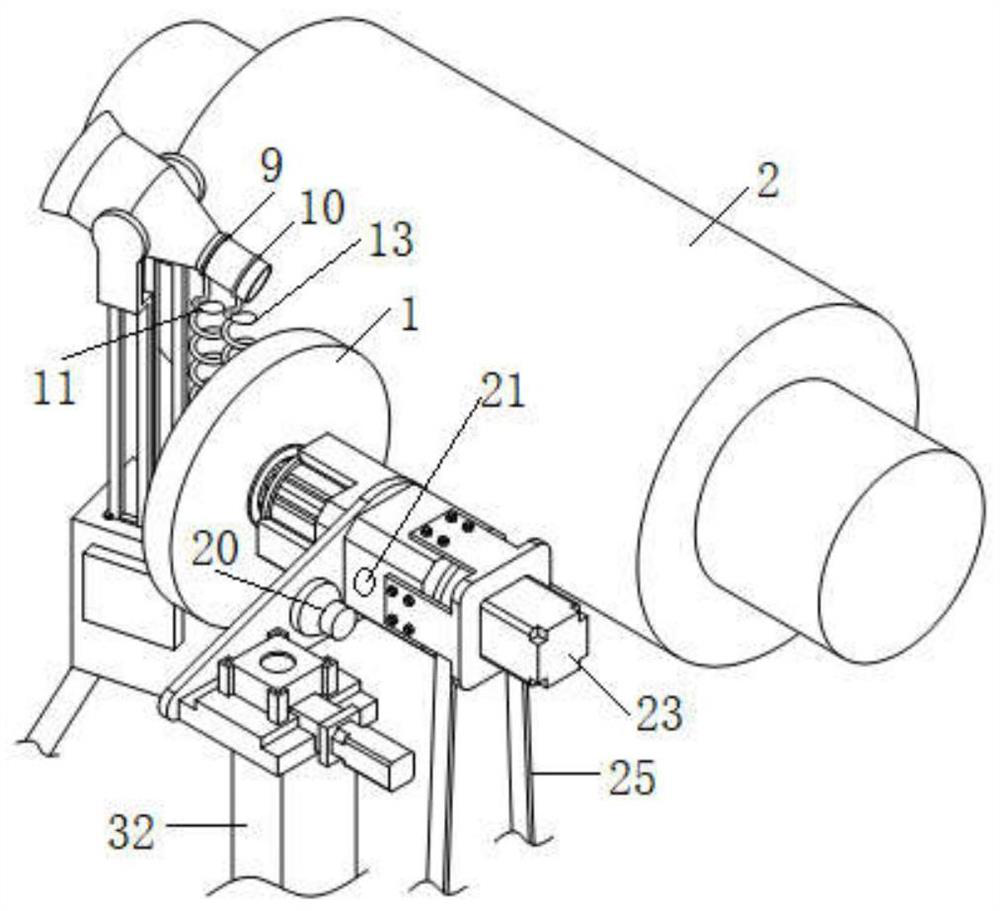

[0034] Such as Figures 1 to 5 A kind of ultrasonic-assisted vaporization cooling double-circle grinding system with fog cannon shown in the present invention comprises: grinding wheel 1, roll 2, grinding wheel driving mechanism, grinding wheel feeding mechanism, fog cannon spraying mechanism and pair of grinding wheel driving mechanism and The control mechanism that controls the spraying mechanism of the fog cannon. The grinding wheel 1 and the roll 2 are circumscribed. The grinding wheel feeding mechanism is used to drive the grinding wheel 1 and the grinding wheel driving mechanism makes a feeding movement along the grinding wheel 1 axis.

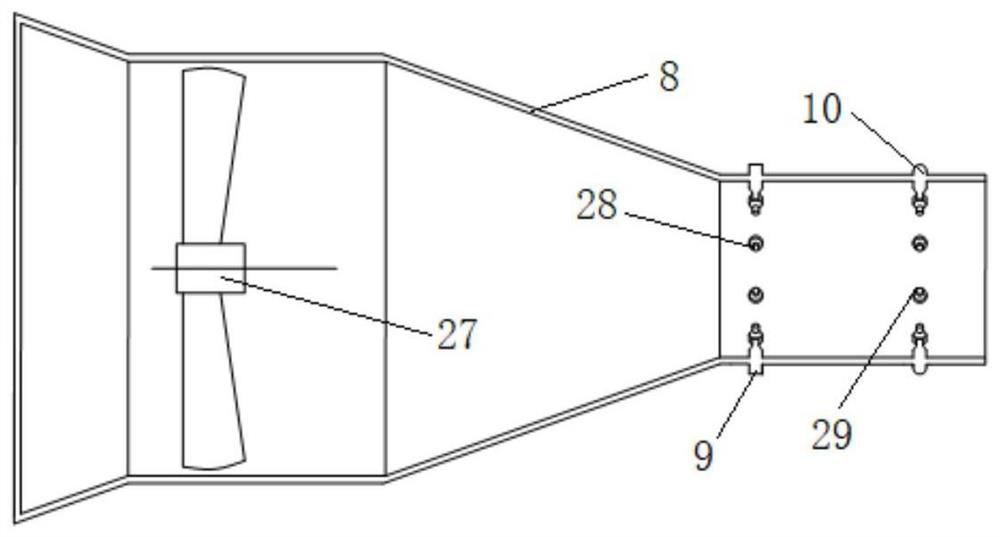

[0035] The spraying mechanism of the fog cannon includes: a fog cannon barrel 8 and a cabinet 5, the top of the cabinet 5 is provided with a double-rod bracket 7, the top of the double-rod bracket 7 is connected with the fog cannon barrel 8 through a rotating shaft, and one side of the fog cannon barrel 8 A locking nut threadedly connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com