Method and system for melting injection molding materials, and information processing terminal

An injection molding and polybutylene terephthalate technology, which is applied in the melting method and system of injection molding materials, and in the field of information processing terminals, can solve the problems of easy product degradation, long drying time, and reduced drying rate, and achieve stability And the effect of good accuracy, large temperature rise and shortened drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0047] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

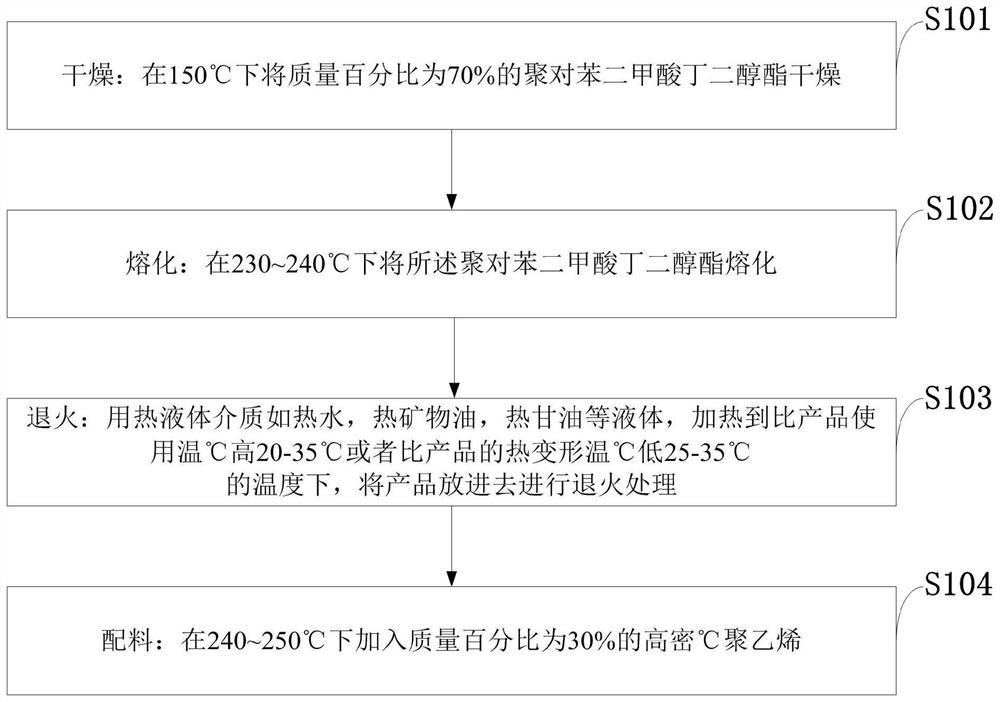

[0048] Such as figure 1 As shown, the melting method of the injection molding material provided by the embodiment of the present invention comprises the following steps:

[0049] S101: drying: drying polybutylene terephthalate with a mass percentage of 70% at 150°C;

[0050] S102: melting: melting the polybutylene terephthalate at 230-240°C;

[0051] S103: Annealing: Use hot liquid medium such as hot water, hot mineral oil, hot glycerin and other liquids to heat the product to a temperature 20-35°C higher than the product's service temperature or 25-35°C lower than the product's heat distortion temperature, and heat the product Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com