Method and system for supplying power by composite power supply

A technology of composite power supply and power supply method, which is applied in the direction of battery/fuel cell control devices, electric vehicles, and capacitor traction. It can solve problems such as affecting the cruising range of vehicles, the performance degradation of lithium-ion batteries, and the shortening of battery life. The effect of control and user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

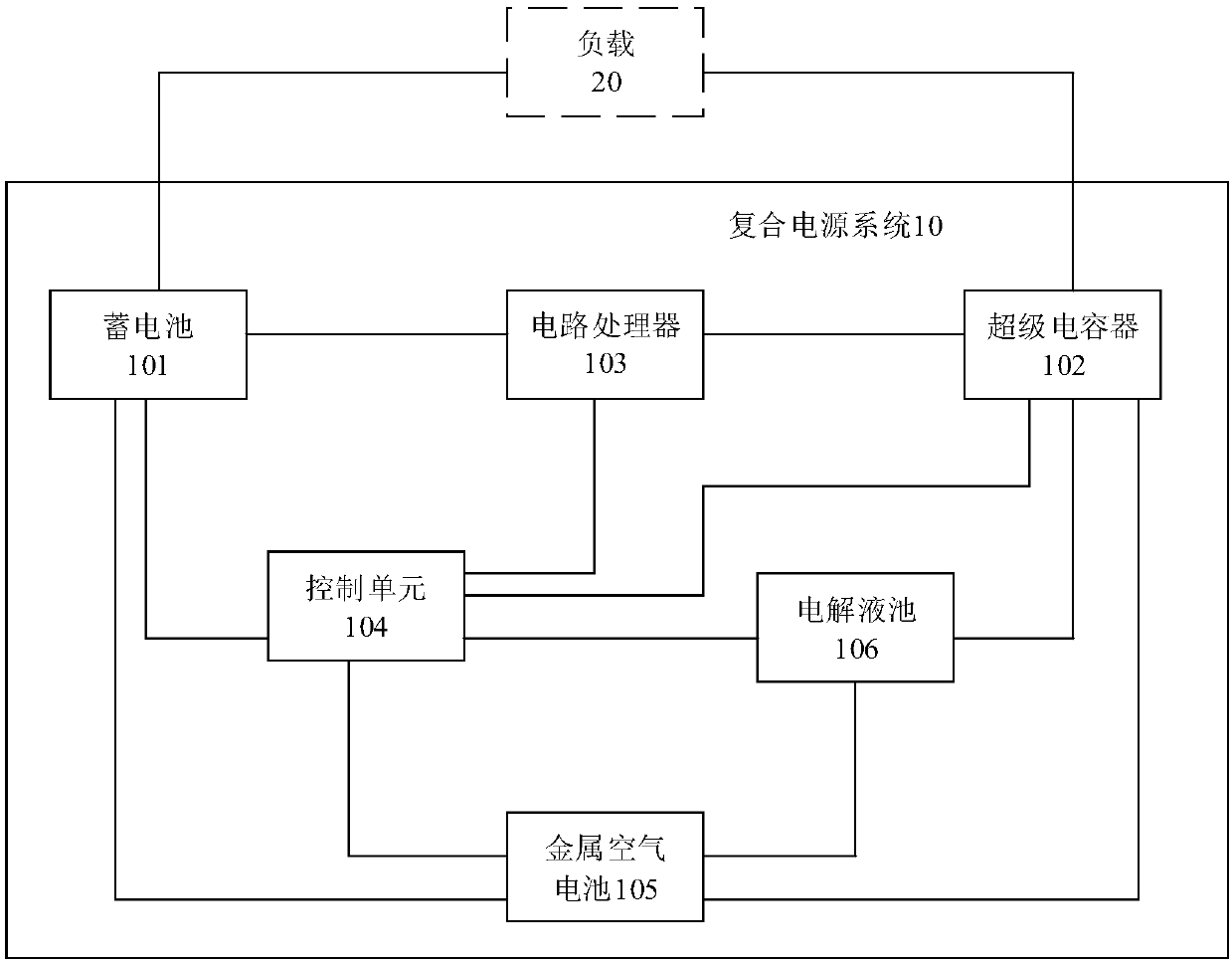

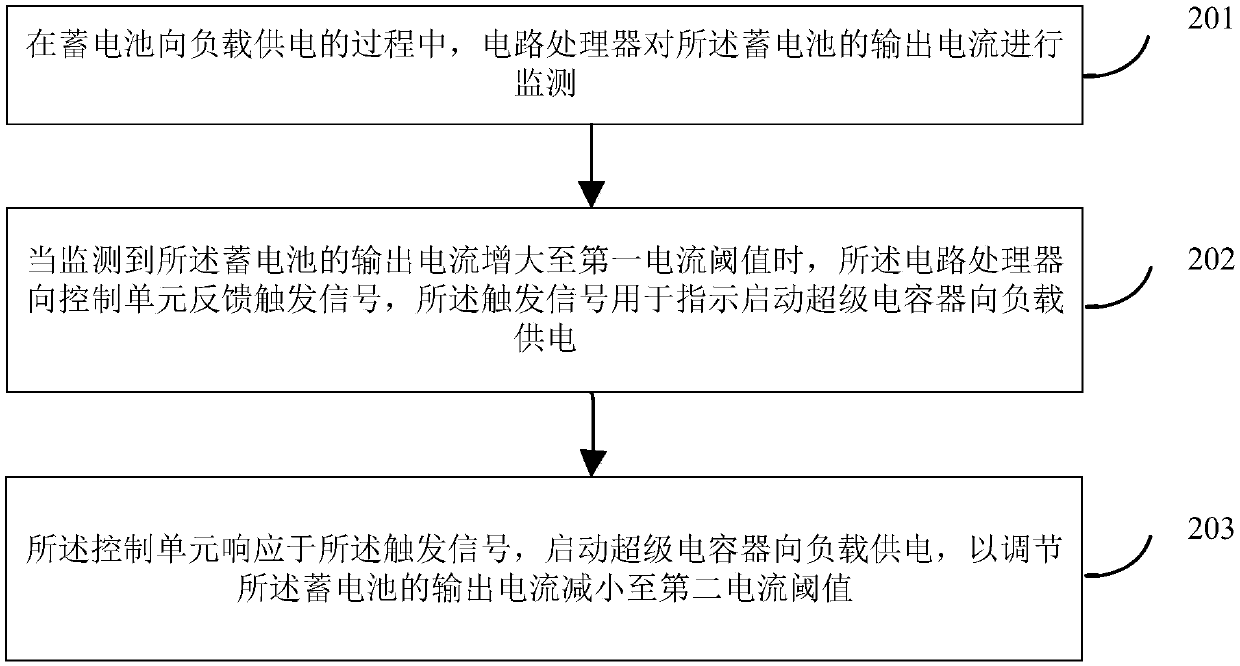

[0035] According to an embodiment of the present invention, the method further includes: during the process of the storage battery and the supercapacitor supplying power to the load at the same time, the circuit processor monitors the respective discharge depths of the storage battery and the supercapacitor to obtain the monitoring results; The unit feeds back a control instruction matched with the monitoring result, so that the control unit responds to the control instruction.

[0036] Wherein, the monitoring result may be that the depth of discharge of the battery or the supercapacitor exceeds a depth threshold; the monitoring result may also be that the ratio between the depth of discharge of the battery and the depth of discharge of the supercapacitor exceeds a preset ratio threshold. Specifically, different responses of the control unit to the two possible monitoring results will be discussed separately next.

[0037] In one embodiment, when the monitoring result is that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com