Preparation and application of cadmium sulfide nanosheet

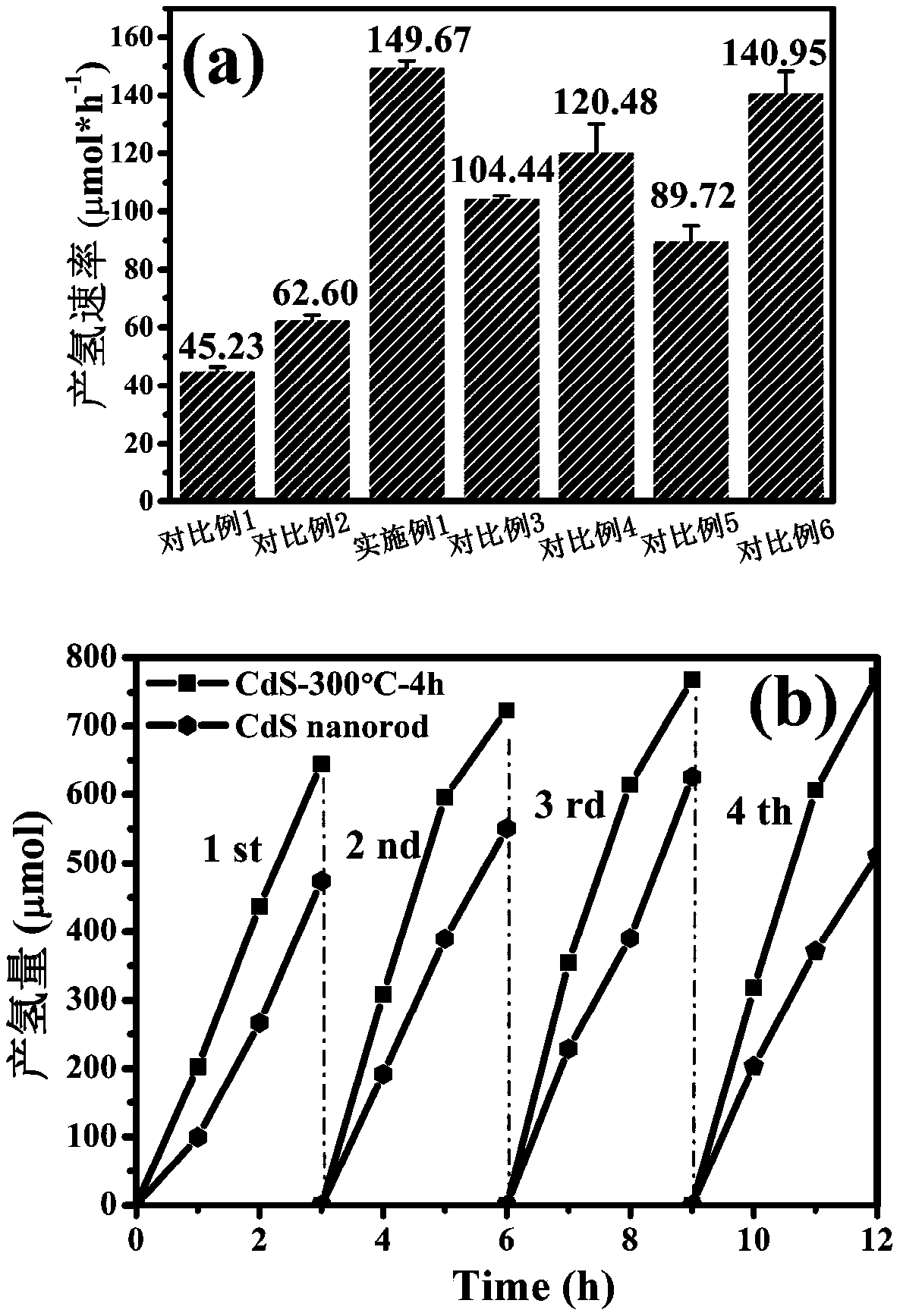

A technology of nanosheets and cadmium sulfide, applied in cadmium sulfide, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problem of reaction equipment with strong heat resistance and corrosion resistance, thick cadmium sulfide nanosheets, and difficulty in large-scale promotion Application and other issues, to achieve the effect of good crystallinity, improved photocatalytic hydrogen production activity, and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

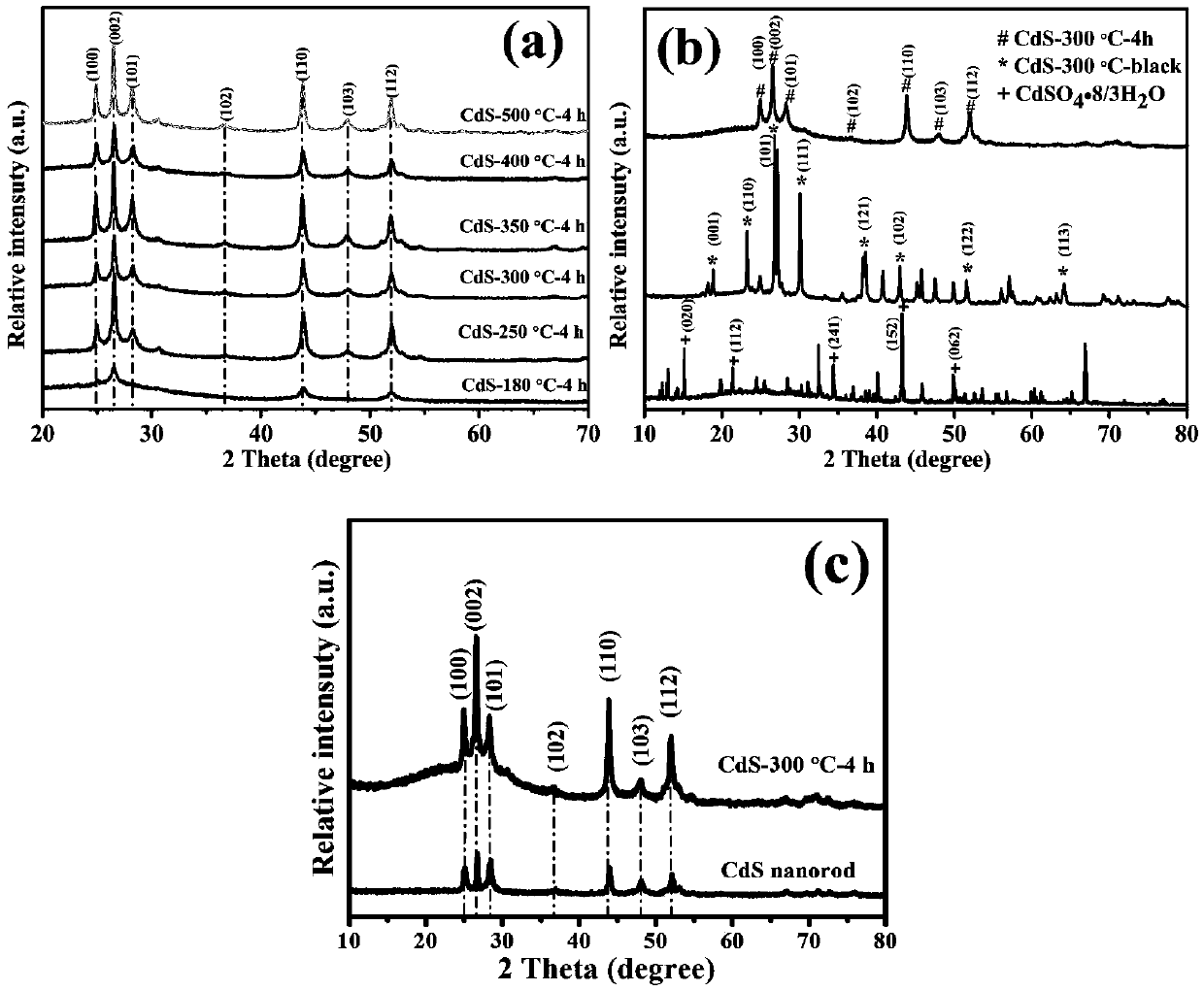

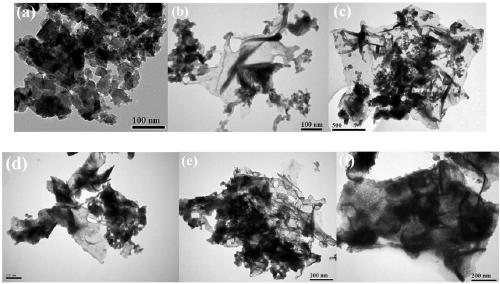

[0025] A preparation method for cadmium sulfide nanosheets, characterized in that it comprises the following steps:

[0026] Step 1. Weigh a certain amount of cadmium salt and place it in a small crucible, cover the pot, and place it in a large crucible;

[0027] Step 2, adding thiourea into the large crucible until the thiourea completely covers the small crucible;

[0028] Step 3. Cover the large crucible after adding thiourea in step 2, and place it in a muffle furnace for calcination. The calcination temperature is 300°C, the heating rate is 10°C / min, and the holding time is 4h. After the reaction is completed, , naturally cooled to room temperature, and taken out;

[0029] Step 4. Grind the yellow granular product in the small crucible taken out in step 3 evenly, wash the obtained powder with deionized water for 3 to 5 times, then centrifuge, and dry the obtained precipitate at 60°C for 12 hours to obtain the described Cadmium sulfide nanosheets.

[0030] Further, the ...

Embodiment 1

[0035] A preparation method for cadmium sulfide nanosheets, characterized in that it comprises the following steps:

[0036] Step 1, take by weighing 0.5g cadmium sulfate (CdSO 4 8 / 3H 2 O (≥99.0%)) is placed in a 50mL small crucible, and after covering the pot, place it in a 100mL large crucible;

[0037] Step 2, fill up 50g of thiourea in the large crucible, so that it can completely cover the small crucible;

[0038] Step 3. Cover the large crucible after adding thiourea in step 2, and place it in a muffle furnace, raise the temperature from room temperature to 300°C at a heating rate of 10°C / min, and keep it warm at 300°C for 4h, and react After completion, cool to room temperature naturally and take out;

[0039]Step 4. Grind the yellow granular product in the small crucible taken out in step 3 evenly, add deionized water to the obtained powder, wash and centrifuge, repeat "cleaning-centrifugal separation" 5 times, and dry the obtained precipitate at 60°C for 12 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com