Low-dust dry-mixed mortar composition and preparation method thereof

A technology of dry-mixed mortar and composition, which is applied in the field of building materials, can solve the problems of large inhalation health threat risk, cure the symptoms but not the root cause, and achieve the effect of good mixing uniformity, high binding force, and uniform distribution of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

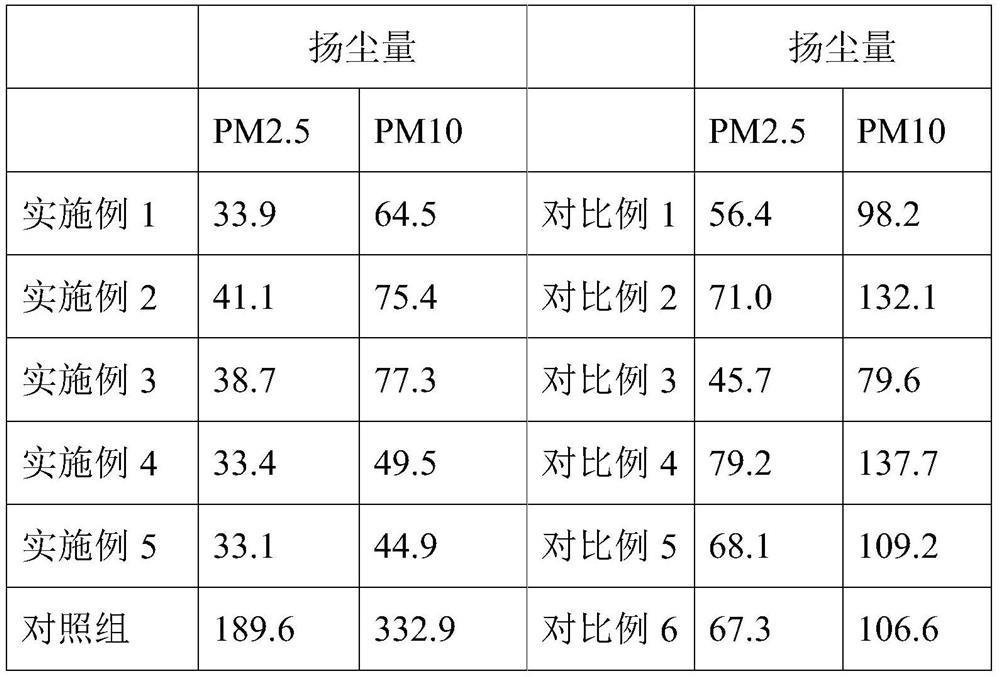

Examples

Embodiment 1

[0053] The low-dust dry-mixed mortar composition is made by including the following components by weight: 30 parts of 42.5 cement, 58 parts of inorganic fine aggregate, 10 parts of mineral admixture, 0.2 part of wood fiber, 0.2 part of cellulose ether, 0.1 part of diethylene glycol, 0.1 part of citric acid, 0.1 part of sodium gluconate, 3 parts of redispersible latex powder, 0.05 part of polyvinyl alcohol solution, 0.05 part of polyacrylamide solution, 0.01 part of pregelatinized starch, 0.01 part of oxidized Starch, 0.01 part dextrin and 0.2 part mineral oil defoamer.

[0054] The method for preparing the low-dust dry-mixed mortar composition comprises the following steps:

[0055] 1) diethylene glycol, citric acid, sodium gluconate are added with water to be formulated with a retarder solution with a total concentration of 40wt%, and pregelatinized starch, oxidized starch and dextrin are added with water to be formulated with a modified solution with a total concentration of...

Embodiment 2

[0059] The low-dust dry-mixed mortar composition is made of the following components by weight: 20 parts of 42.5 cement, 50 parts of inorganic fine aggregate, 5 parts of mineral admixture, 0.1 part of wood fiber, 0.3 part of cellulose ether, 0.05 part diethylene glycol, 0.15 part citric acid, 0.15 part sodium citrate, 1 part redispersible latex powder, 0.01 part polyvinyl alcohol solution, 0.02 part polyacrylamide solution, 0.03 part pregelatinized starch and 0.1 part mineral Oil defoamer.

[0060] The method for preparing the low-dust dry-mixed mortar composition comprises the following steps:

[0061] 1) Diethylene glycol, citric acid, sodium gluconate are added with water to prepare a retarder solution with a total concentration of 30wt%, and pregelatinized starch is added with water to be prepared with a 5wt% modified starch solution; polyvinyl alcohol is added with water to prepare To become a 2wt% solution, each polyacrylamide is heated by adding water to prepare a 5wt%...

Embodiment 3

[0065] The low-dust dry-mixed mortar composition is made of the following components by weight: 40 parts of 42.5 parts of cement, 65 parts of inorganic fine aggregate, 15 parts of mineral admixture, 0.3 part of wood fiber, 0.1 part of cellulose ether, 0.2 part of citric acid, 0.1 part of sodium gluconate, 6 parts of redispersible latex powder, 0.02 part of polyvinyl alcohol solution, 0.1 part of polyacrylamide solution, 0.01 part of pregelatinized starch, 0.02 part of oxidized starch, 0.01 part of dextrin and 0.3 part of mineral oil defoamer.

[0066] The method for preparing the low-dust dry-mixed mortar composition comprises the following steps:

[0067] 1) citric acid, sodium gluconate are added with water to be mixed with the retarder solution that total concentration is 50wt%, and pregelatinized starch, oxidized starch and dextrin are added with water and are mixed with the modified starch solution that total concentration is 2wt%; Vinyl alcohol is added with water to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com