An early-strength sulfate-resistant cement

A sulfate-resistant cement, early-strength technology, applied in the field of cement concrete filling, can solve the problems of compressive strength and corrosion resistance that need to be improved, difficult to achieve, complicated raw materials and processes, etc., so as to shorten the curing time and reduce energy consumption. , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

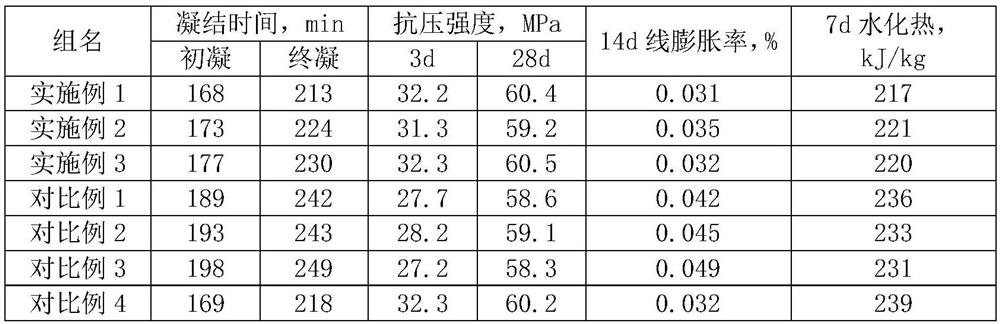

Examples

Embodiment 1

[0024] For the early-strength sulfate-resistant cement provided in this example, the raw materials of the cement clinker used include 78wt% of calcareous materials, 6.8wt% of silica-alumina materials, 10.6wt% of ferrous materials, 4wt% of phosphorus slag, and 0.6 wt% of catalysts. wt%; the loss on ignition of the cement clinker is less than 0.3%, the free calcium oxide is less than 1.0%, and the mineral composition of the cement clinker is C 3 S 51.3%, C 2 S23.8%, C 4 AF 19.5%, C 3 A 2.1 percent.

[0025]The preparation method of cement clinker is: grind and dry calcareous materials, silicon-aluminum materials, and iron materials into powders with an average particle size of 27 μm and sieve 12% of them at 80 μm, then calcinate at 1380 ° C for 1 hour, and finally press Rapid cooling at 60°C / min to room temperature.

[0026] The raw materials of the early-strength sulfate-resistant cement in this embodiment are 88% cement clinker, 0.04% grinding aid, 8% slag fine powder, and...

Embodiment 2

[0028] The raw material composition of the early-strength sulfate-resistant cement provided in this example, and the preparation method of the cement clinker are the same as those in Example 1, except that the raw materials of the cement clinker used include 74wt% of calcareous materials, silica-alumina 12wt% of cement clinker, 11.2wt% of iron material, 3wt% of phosphorus slag, 0.8wt% of catalyst, and the mineral composition of cement clinker is C 3 S48.5%, C 2 S 25.3%, C 4 AF 22.6%, C 3 A 1.7%.

Embodiment 3

[0030] The raw material composition of the early-strength sulfate-resistant cement provided in this example, and the preparation method of the cement clinker are the same as those in Example 1, except that the raw materials of the cement clinker used include 80 wt% of calcareous materials, silica-alumina 3.6wt% of cement clinker, 13wt% of iron material, 3wt% of phosphorus slag, 0.4wt% of catalyst, and the mineral composition of cement clinker is C 3 S53.9%, C 2 S 22.3%, C 4 AF 20.1%, C 3 A 1.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com