Concrete and preparation method thereof

A technology for concrete and mixture, applied in the field of concrete and its preparation, can solve the problems of reduced service life of buildings, poor environmental protection performance, short service life, etc., and achieves improved weather resistance and waterproof performance, good corrosion resistance and durability, The effect of waterproof durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

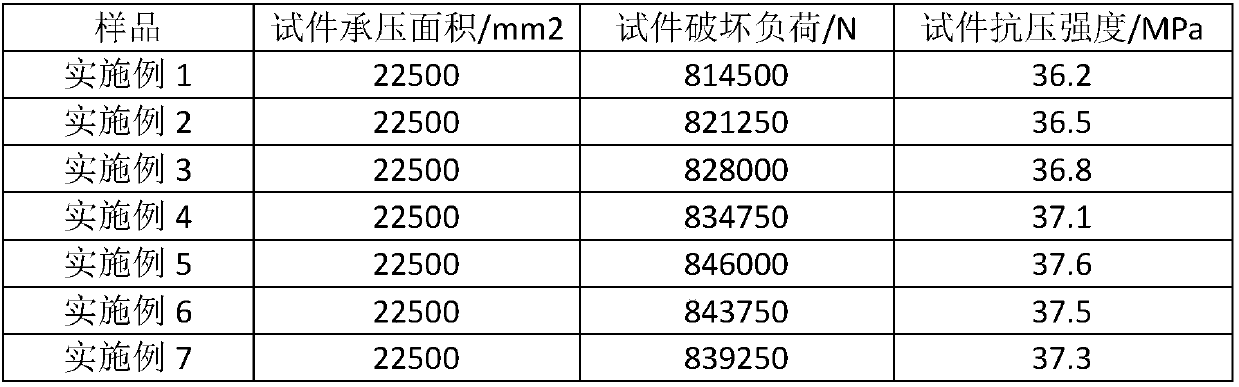

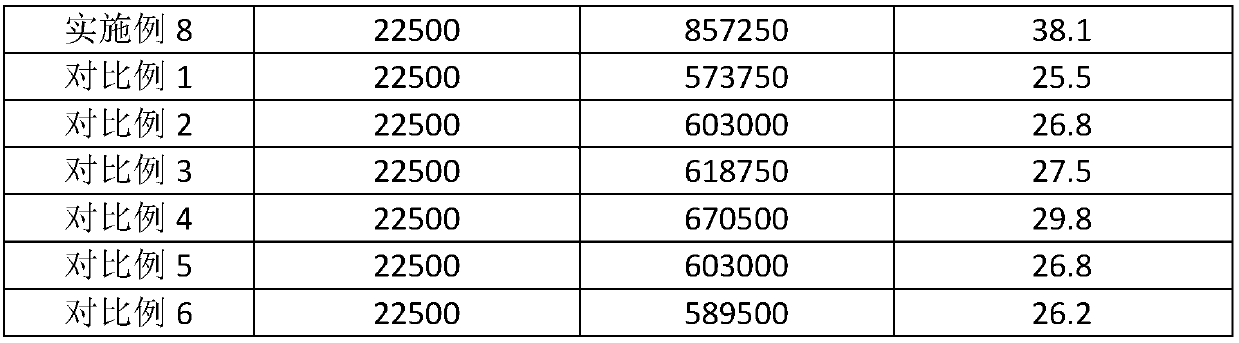

Examples

Embodiment 1

[0046] For bluestone, pumice and sand, the specific treatment process is as follows:

[0047] The bluestone and pumice were pulverized into fine bluestone and fine pumice with a size of 1 mm, respectively, and the bluestone and pumice were pulverized into coarse bluestone and coarse pumice with a size of 10 mm, respectively, and the sand was passed through a 5-mesh screen.

[0048] A preparation method of concrete comprises the steps:

[0049] Put cement 73kg, bluestone 154.8kg (coarse bluestone 103.2kg+fine bluestone 51.6kg), pumice 17.2kg (coarse pumice 11.5kg+fine pumice 5.7kg), 130kg sand, 11kg fly ash, 1kg polypropylene fiber and 1kg steel fiber in dry Stir and mix evenly to obtain the first mixture;

[0050] Weigh 1kg of silicon hexadecyltrimethylsilane, 1.3kg of polycarboxylate water-reducing agent, 2.2kg of SK-Y expansion agent and 181kg of water, and weighed hexadecyltrimethylsilane, polycarboxylate Acid water reducer, SK-Y expansion agent and water are mixed unifor...

Embodiment 2

[0053] For bluestone, pumice and sand, the specific treatment process is as follows:

[0054] The bluestone and pumice were pulverized into fine bluestone and fine pumice with a size of 2mm, respectively, and the bluestone and pumice were pulverized into coarse bluestone and coarse pumice with a size of 15mm, and the sand was passed through a 10-mesh screen.

[0055] A preparation method of concrete comprises the steps:

[0056] Mix 73kg of cement, 157.5kg of bluestone (105kg of coarse bluestone + 52.5kg of fine bluestone), 31.5kg of pumice (21kg of coarse pumice + 10.5kg of fine pumice), 140kg of sand, 11kg of fly ash, 1.5kg of polypropylene fiber and 1kg of steel fiber in dry mixing. Mix uniformly down to obtain the first mixture;

[0057] Weigh 0.5kg of silicon hexadecyltrimethylsilane, 2kg of polycarboxylate water-reducing agent, 2kg of SK-Y expansion agent and 178kg of water, and weighed hexadecyltrimethylsilane, polycarboxylic acid The water reducing agent, SK-Y expans...

Embodiment 3

[0060] For bluestone, pumice and sand, the specific treatment process is as follows:

[0061] The bluestone and pumice were pulverized into fine bluestone and fine pumice with a size of 9mm, respectively, and the bluestone and pumice were pulverized into coarse bluestone and coarse pumice with a size of 20mm, and the sand was passed through a 15-mesh screen.

[0062] A preparation method of concrete comprises the steps:

[0063] Mix 73kg of cement, 162kg of bluestone (121.5kg of coarse bluestone + 40.5kg of fine bluestone), 27kg of pumice (20.25kg of coarse pumice + 6.75kg of fine pumice), 130kg of sand, 11kg of fly ash, 1kg of polypropylene fiber and 0.4kg of steel fiber in dry mixing. Mix uniformly down to obtain the first mixture;

[0064] Weigh 1.7kg of silicon hexadecyltrimethylsilane, 2.8kg of polycarboxylate water-reducing agent, 1kg of SK-Y expansion agent and 177kg of water, and weighed hexadecyltrimethylsilane, polycarboxylate Acid water reducer, SK-Y expansion age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com