PI matrix resin and flame-retardant colorless transparent polyimide film prepared from same

A technology of transparent polyimide and matrix resin, applied in the field of flame-retardant colorless transparent polyimide film, can solve the problems of loss of film transparency, and achieve high glass transition temperature, excellent heat resistance stability, The effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

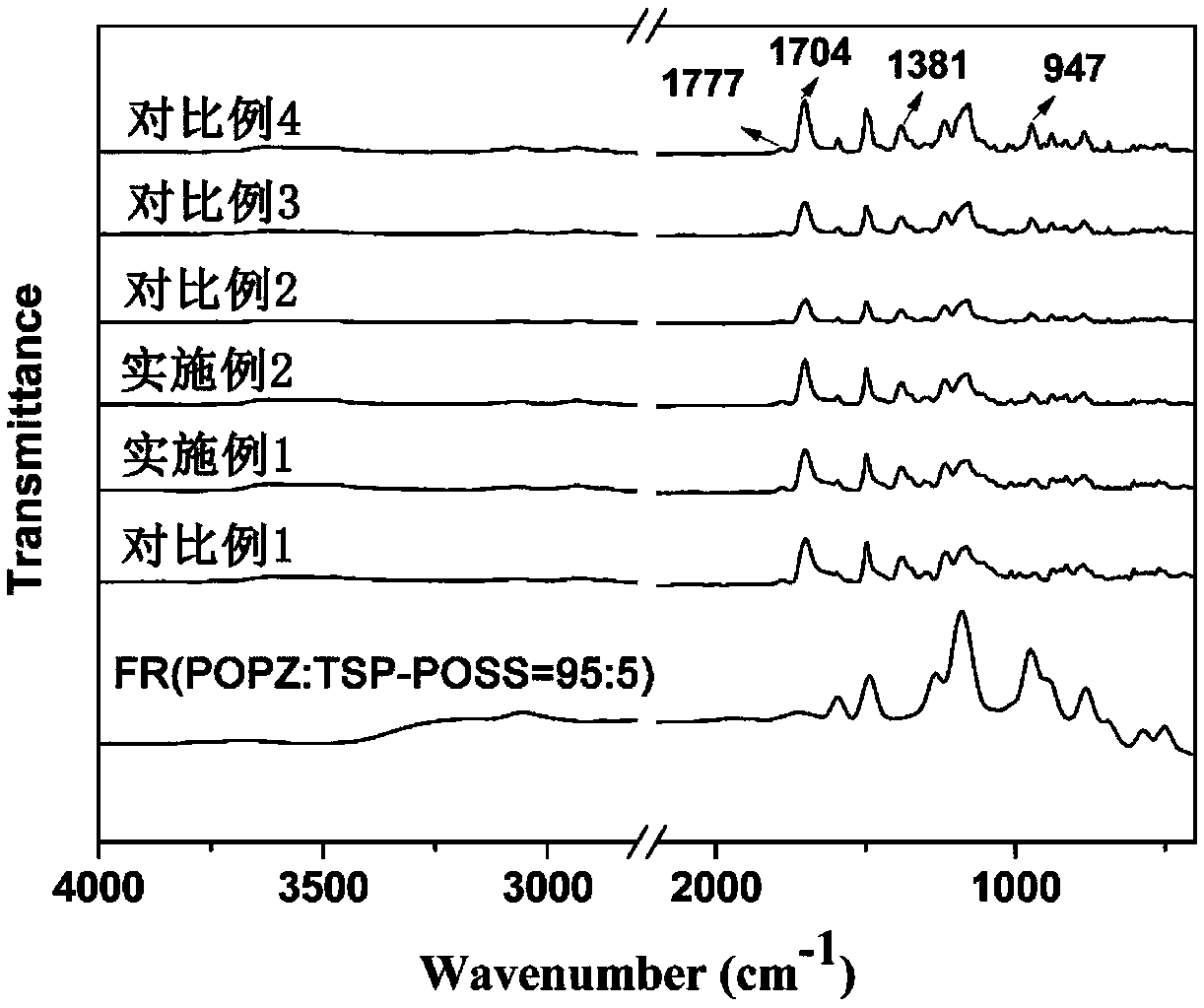

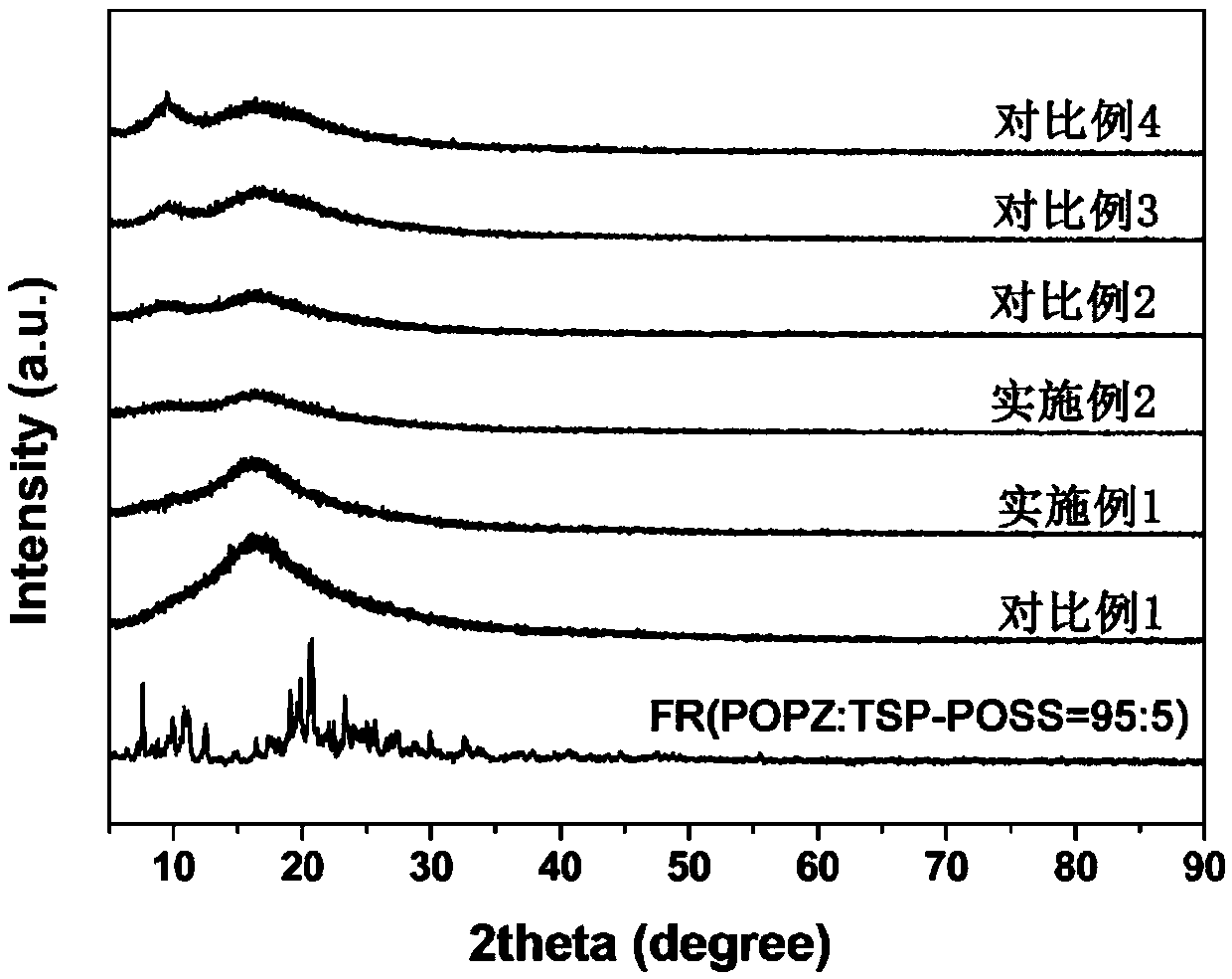

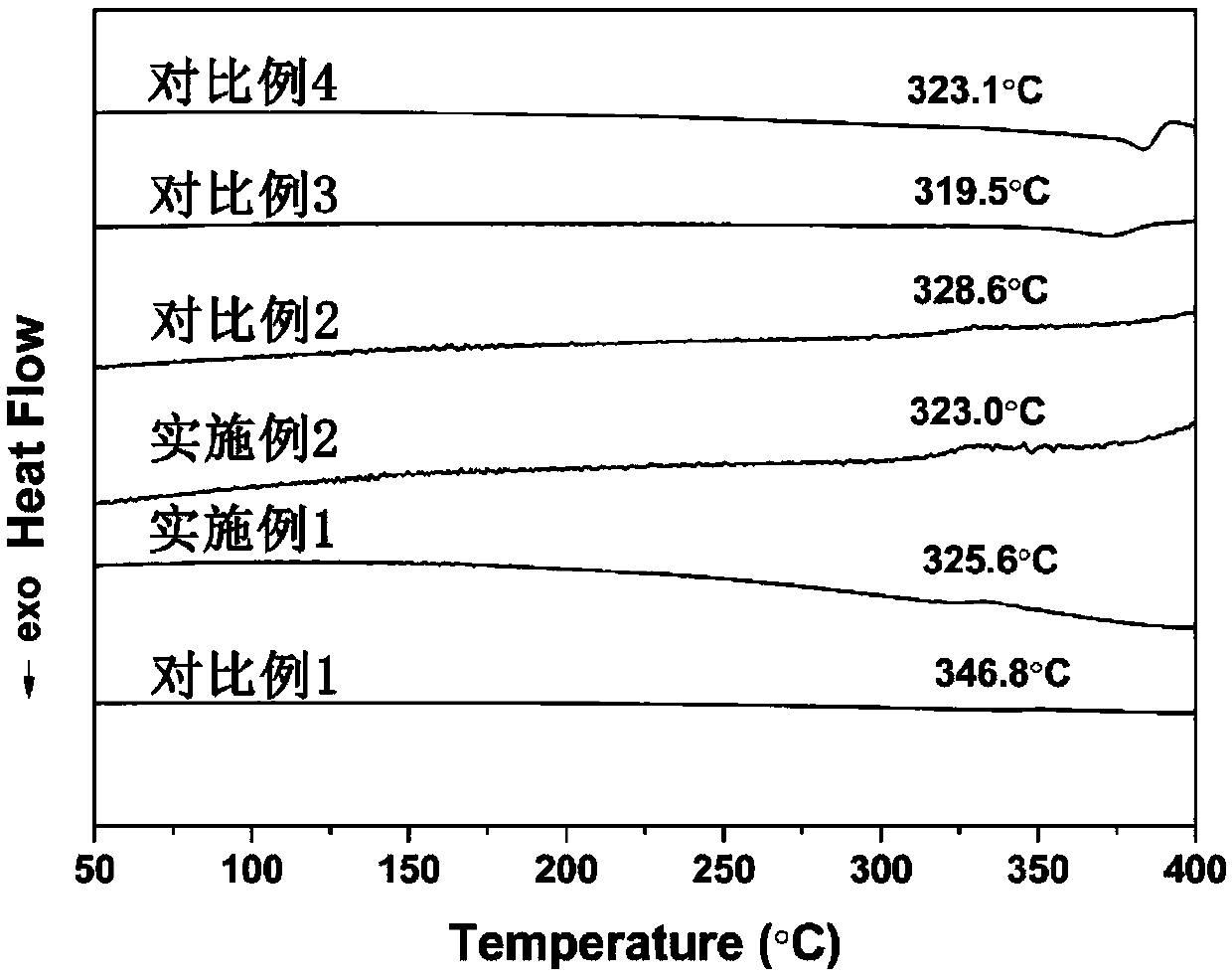

[0063] The PI matrix resin described in this example is prepared by reacting CHDA, an alicyclic dianhydride monomer, and ODA, an aromatic diamine monomer. The specific preparation process includes:

[0064] Add 20.2040g (0.1mol) ODA and 150g NMP into a 500mL three-neck flask equipped with a heating mantle, mechanical stirring, thermometer, water separator, and reflux condenser; feed nitrogen gas and mechanically stir for 20 minutes to obtain a clear solution; stir Add 22.4170g (0.1mol) CHDA at the same time, the viscosity of the system gradually increases; at the same time, add 20g NMP, stir at room temperature for 30min, to obtain a viscous solution; When the temperature rises to 130-140°C, the toluene / water azeotrope evaporates from the water separator; maintain reflux for dehydration until no water drops come out of the system; continue to heat up to 180°C, keep the temperature for 3 hours, stop heating, and naturally cool to room temperature ; Slowly pour the viscous liqui...

Embodiment 2

[0070] The PI matrix resin described in this example is prepared by reacting CHDA, an alicyclic dianhydride monomer, and ODA, an aromatic diamine monomer. The specific preparation process is the same as in Example 1.

[0071] The flame-retardant colorless and transparent polyimide film described in this embodiment is prepared by the PI base resin prepared above in conjunction with a flame retardant FR (FR mass accounts for 10wt% of the total mass of the PI film, mass ratio), and the specific preparation process includes:

[0072] Take 10g of the above PI resin and dissolve it in 40g DMAc to obtain a PI solution; at the same time, dissolve 1.1111g FR (POPZ:TSP-POSS=95:5, mass ratio) in 4.4444g DMAc and pour it into the resin solution to prepare 20wt % PI composite solution; after the solution is mixed evenly, it is evenly coated on the surface of a clean glass plate by an automatic film coating machine, placed in a 100-class clean program temperature-controlled drying oven, and ...

Embodiment 3

[0105] The PI matrix resin described in this example is prepared by reacting the alicyclic dianhydride monomer HBPDA and the aromatic diamine monomer ODA, and the specific preparation process is the same as in Example 1.

[0106] The flame-retardant colorless transparent polyimide film described in this example is prepared from the PI matrix resin prepared above together with a flame retardant FR (POPZ:TSP-POSS=95:5, mass ratio) (the mass of FR accounts for the total amount of PI film 10wt% of mass, mass ratio).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com