Chemically modified transparent flame-retardant PET masterbatches and preparation method and application thereof

A flame-retardant masterbatch and chemical modification technology, which is applied in the field of engineering plastics, can solve the problems of complex manufacturing process, poor compatibility, and affecting the mechanical properties of materials, and achieve the effect of simple preparation method and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

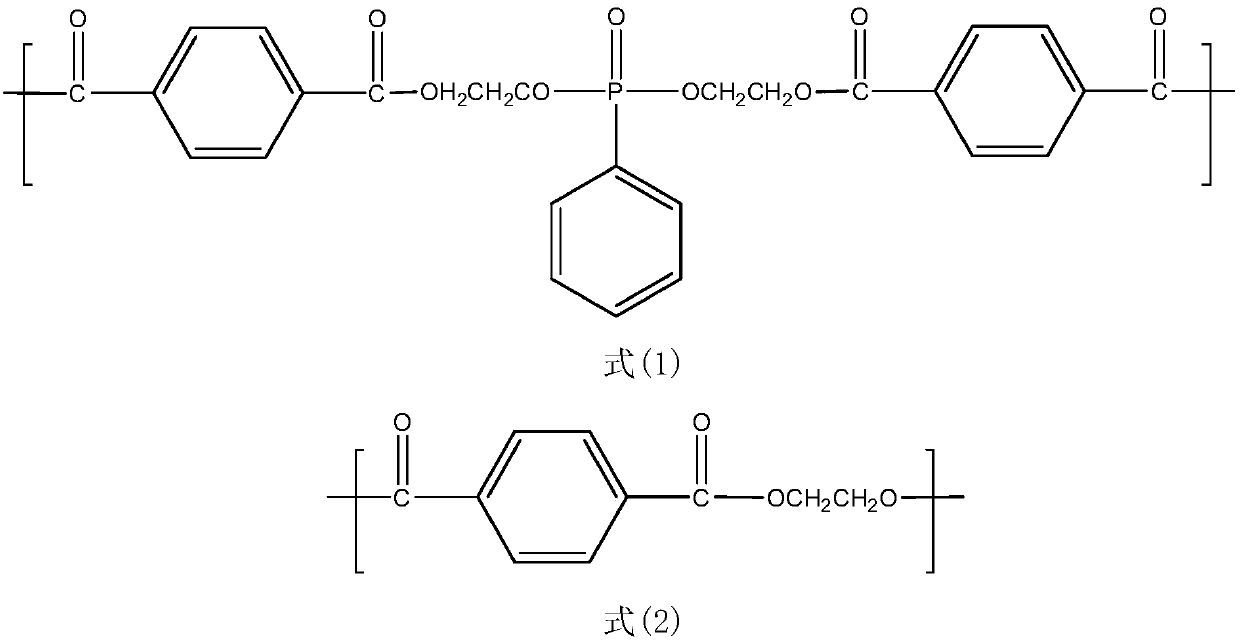

[0040] Preparation of chemically modified PET resin:

[0041] The preparation of chemically modified PET resin is obtained by pre-esterifying ethylene glycol (EG) and phenylphosphoryl dichloride (BPOD) and then polycondensing it with terephthalic acid (PTA). The preparation process is as follows:

[0042] 1), in the pre-esterification stage, according to the EG:BPOD molar ratio of 3-5:1, put the material into the esterification reactor, keep the temperature at 40-70°C, react for 1-5 hours, and reduce the temperature at 110-120°C after stopping the reaction. The excess ethylene glycol is steamed by pressure, and the synthesis reaction formula is:

[0043]

[0044] 2) In the polycondensation stage, after the pre-esterification is completed, the PTA:EG molar ratio of 1:1.2-1.3 is added to the reactor for beating, and then the stabilizer and polycondensation catalyst Sb are added 2 o 3 , react at 230-270°C for 3-8 hours, stop the reaction when the acid value of the system (...

Embodiment 1-10

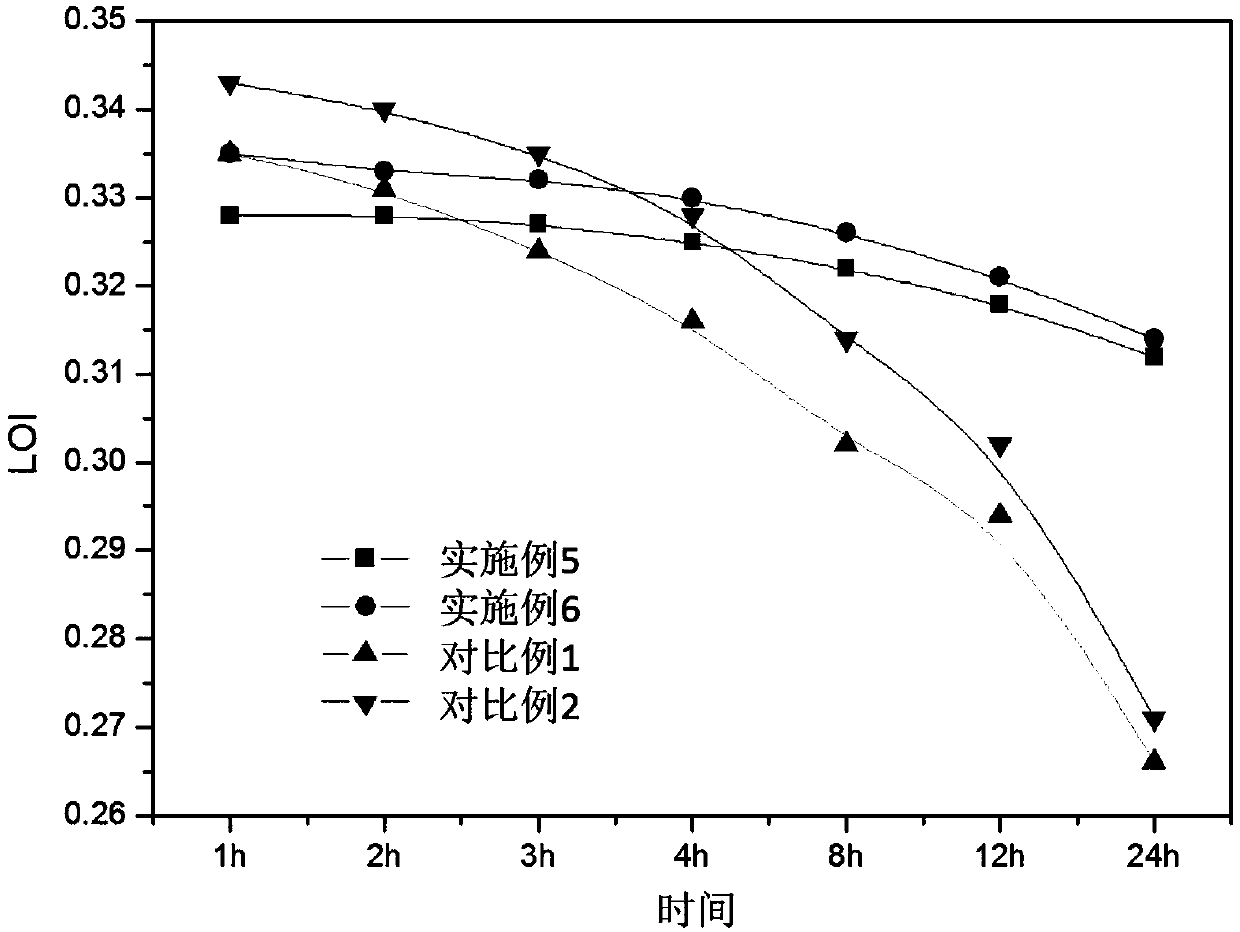

[0059] Examples 1-10 It is the PET masterbatch obtained according to the above-mentioned preparation method, and its raw material composition and mass percentage are as shown in Table 3 below:

[0060] table 3

[0061]

[0062]

Embodiment 11

[0095] Example 11: The PET masterbatch and anti-blocking agent of Example 5 are fully mixed in a high-speed mixer and then melt-extruded at 280-300 ° C. The anti-blocking agent is a mixture of barium sulfate and cross-linked polymethyl acrylate After being cooled by a cold roll at 20-30°C, it is formed into a cast sheet. The cooled cast sheet is first preheated at 82°C and then stretched longitudinally. The stretching temperature is 120-140°C, and the stretching ratio is 3 times. Transverse stretching, the stretching temperature is 120-140°C, the stretching ratio is 3 times, after biaxial stretching, it is heat-set at 160-190°C, and it is wound to obtain a flame-retardant transparent PET film with a total thickness of 150μm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com