Preparation method of novel polyurethane material with excellent shape memory property

A technology of polyurethane material and polyurethane rubber is applied in the field of preparation of new polyurethane materials with excellent shape memory properties, which can solve the problems of mechanical properties decline, polymer aging, product discoloration, etc. Good impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the novel polyurethane material with excellent shape memory performance provided by the present invention comprises:

[0034] Step 1: 85-120 parts of polyurethane rubber, 28-45 parts of nitrile rubber, 8-12 parts of stearic acid, 1-7 parts of ethylene-vinyl acetate copolymer, 4.5-6 parts of vulcanization accelerator, 1-3 parts of heat stabilizer, 4-7 parts of nano-alumina, 2-4 parts of coulon resin, 1-3 parts of diisodecyl phthalate, 1-2 parts of antioxidant, 1-2 parts of hydroxyl silicone oil Parts were mixed evenly to obtain a mixture;

[0035] Vapor-phase SiO 2 After the powder and the mixture are fully mixed with a colloid mill, dehydration is carried out at a vacuum degree of 0.15Mpa and a temperature of about 184°C to 198°C, and the dehydration time is 2 to 4 hours;

[0036] Step 2. After releasing the vacuum, cool down to 60-75°C, add 15-25 parts of toluene diisocyanate, stir and slowly raise the temperature to 85°C under nitrogen atmo...

experiment example 1

[0053] Experimental example 1, in order to verify the physical performance of polyurethane material of the present invention, adopt same experimental condition to manufacture a plurality of samples and carry out mechanical performance test:

[0054] Polymerize to obtain mixture by weight fraction;

[0055] Vapor-phase SiO 2 After the powder and the mixture are fully mixed with a colloid mill, dehydration is carried out at a vacuum degree of 0.15Mpa and a temperature of about 184°C to 198°C, and the dehydration time is 2 to 4 hours;

[0056] Step 2. After releasing the vacuum, cool down to 60-75°C, add 15-25 parts of toluene diisocyanate, stir and slowly raise the temperature to 85°C under nitrogen atmosphere, and keep warm for 2-3 hours;

[0057] Step 3, vacuum defoaming for 0.8h to obtain a prepolymer;

[0058] Step 4, measure the -NCO group content in the prepolymer, according to the content, add the chain extender, stir evenly,

[0059] Chain extender adds parts by weigh...

experiment example 2

[0075] Step 1, the gas phase SiO 2 After the powder and the mixture are fully mixed with a colloid mill, dehydration is carried out at a vacuum degree of 0.15Mpa and a temperature of 184°C to 198°C, and the dehydration time is 2 to 4 hours;

[0076] Step 2. After releasing the vacuum, cool down to 60-75°C, add 15-25 parts of toluene diisocyanate, stir and slowly raise the temperature to 85°C under nitrogen atmosphere, and keep warm for 2-3 hours;

[0077] Step 3, vacuum defoaming for 0.8h to obtain a prepolymer;

[0078] Step 4, measure the -NCO group content in the prepolymer, according to the content, add the chain extender, stir evenly,

[0079] Chain extender adds parts by weight as:

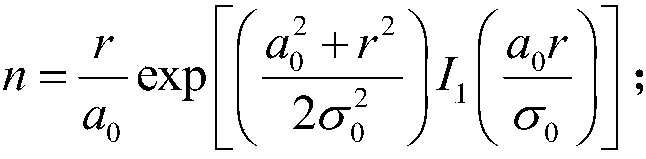

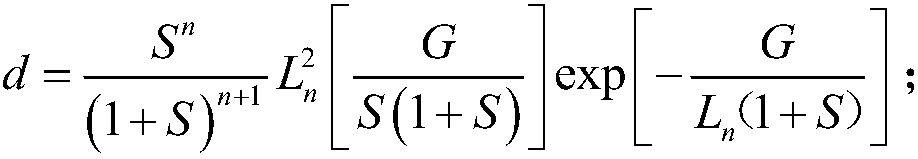

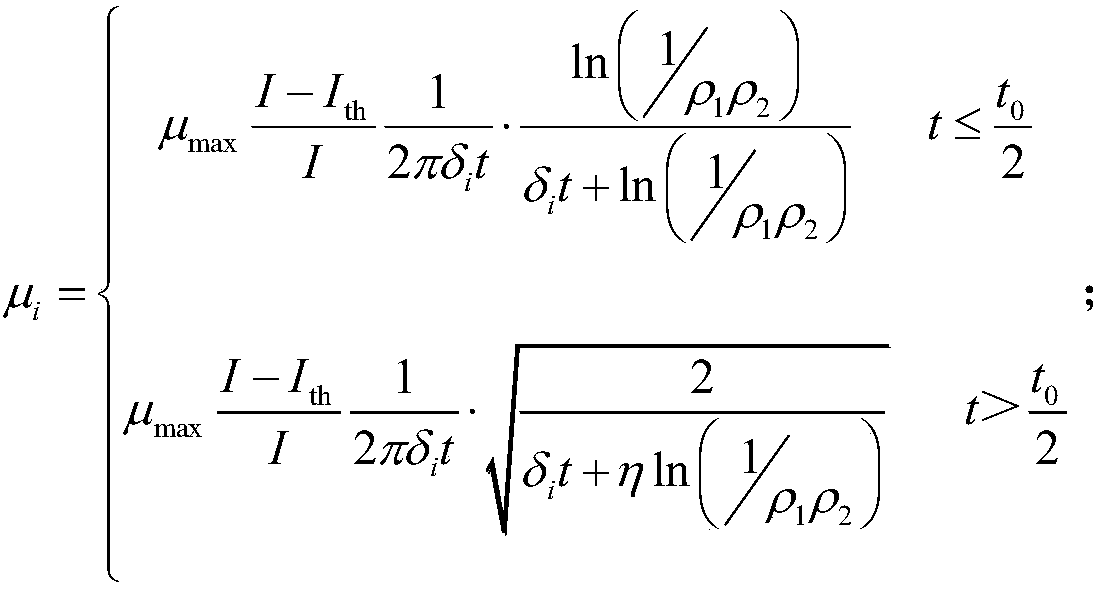

[0080]

[0081] Wherein, n is the parts by weight of chain extender, I 1 is the -NCO group content in the prepolymer, r is the water mass fraction of the chain extender, a 0 is the mass fraction of water in the mixture obtained in step 1, σ 0 is a proportionality factor.

[0082] Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com