A method for synchronously reducing the content of high-ring, middle-ring and low-ring pahs in biomass pyrolysis oil

A biomass pyrolysis technology for oil and biomass, applied in the field of biomass energy, can solve problems such as the inability to control the content of PAHs, achieve the effect of inhibiting the formation of PAHs and reducing environmental health risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Pyrolysis of biomass

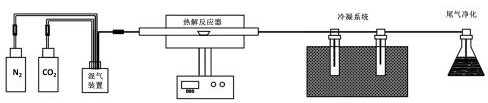

[0037] The schematic diagram of the biomass pyrolysis test flow device is as follows: figure 1 As shown, the specific process is as follows:

[0038](1) Put wood chips or a mixture of Fe / HZSM-5 and wood chips in a mass ratio of 1:1 into the porcelain boat;

[0039] (2) The tube furnace is fed with N 2 gas or N 2 with CO 2 Mix the gas for about 20 minutes, remove the air in the furnace, and raise the temperature to 500°C;

[0040] (3) Place the porcelain boat filled with materials in step (1) in a tube furnace, pyrolyze for 5 minutes, then collect the pyrolysis oil through the condensation system, and weigh it.

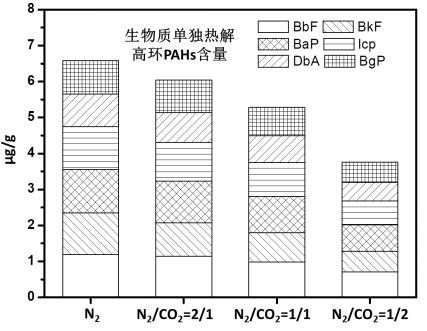

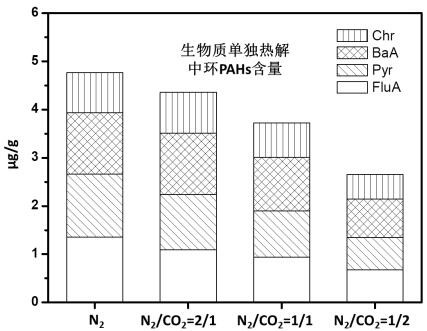

[0041] According to the above-mentioned process, set 4 treatment groups, the Fe / HZSM-5 that each treatment group adopts and the kind of gas that pass into are shown in Table 1, wherein also have 2 control groups, in the control group except the gas that pass into is different Except, other conditions were the same as the treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com