Propeller-driven left-right swing cutter suction type dredging robot with track correction function

A propeller-driven, left-right swinging technology, applied in the field of robotics, can solve problems such as endangering the safety of the main canal, and achieve the effect of high silt suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, a propeller-driven submarine swinging left and right twisting suction dredging robot is provided, which can realize underwater harmless continuous movement and rapid dredging.

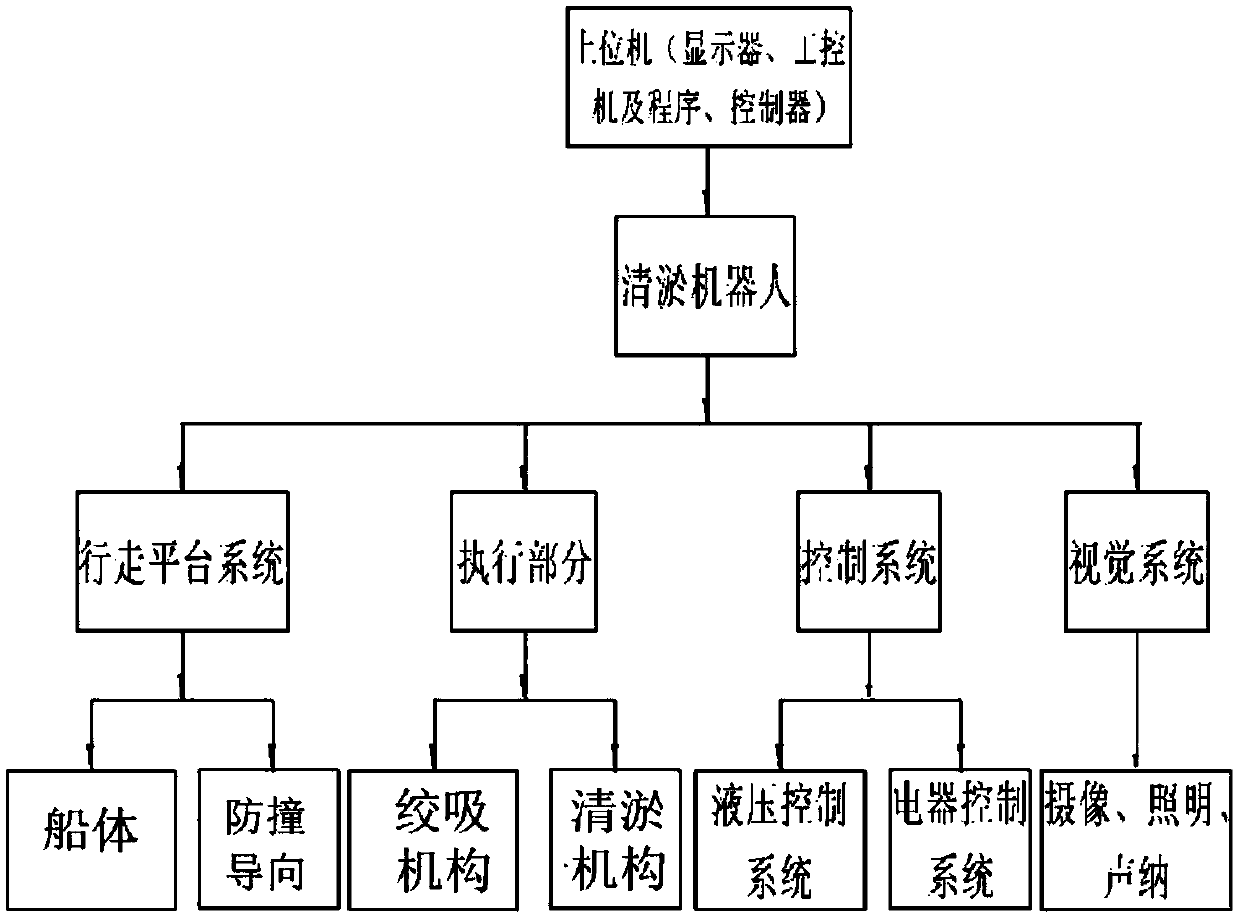

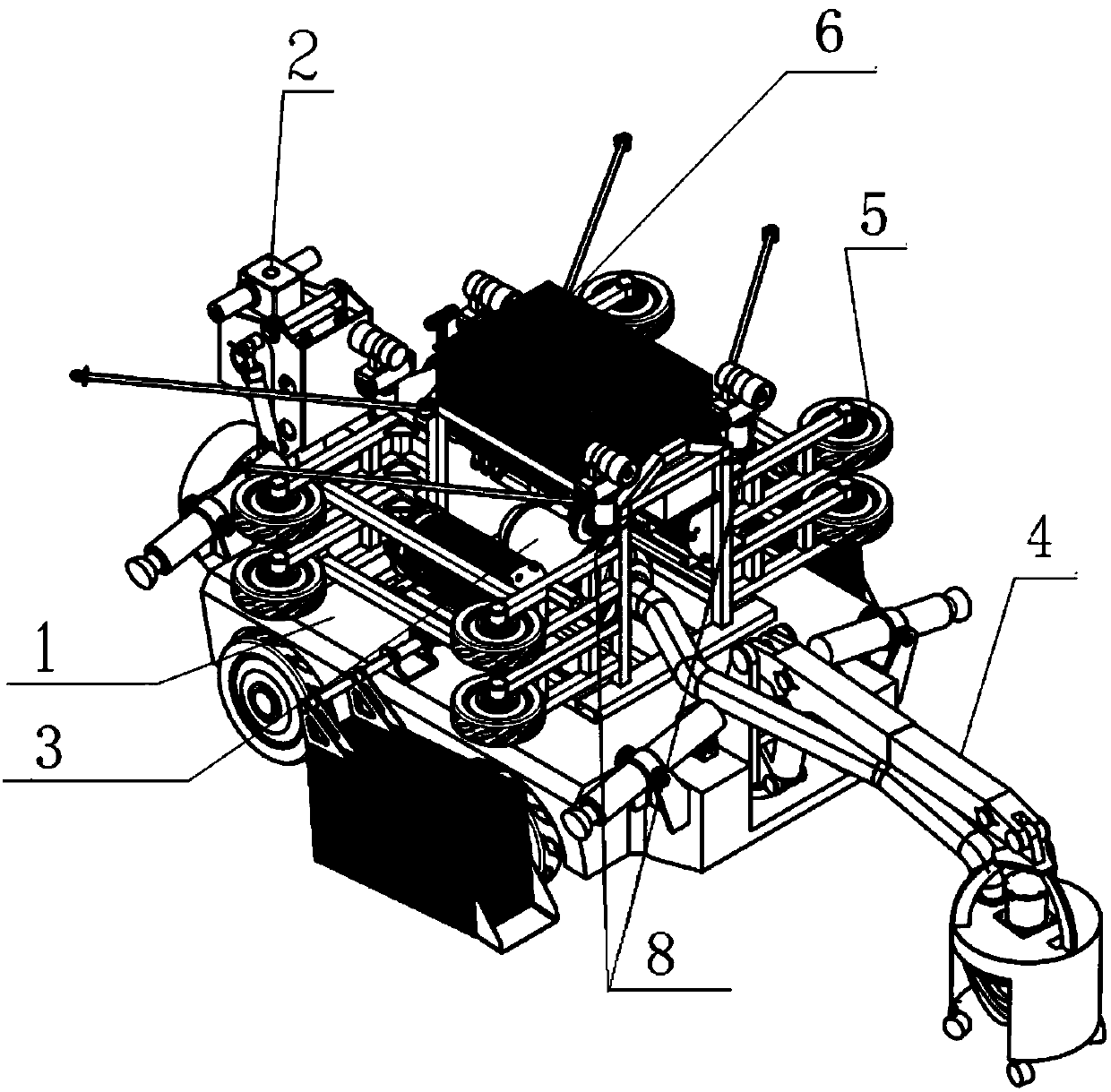

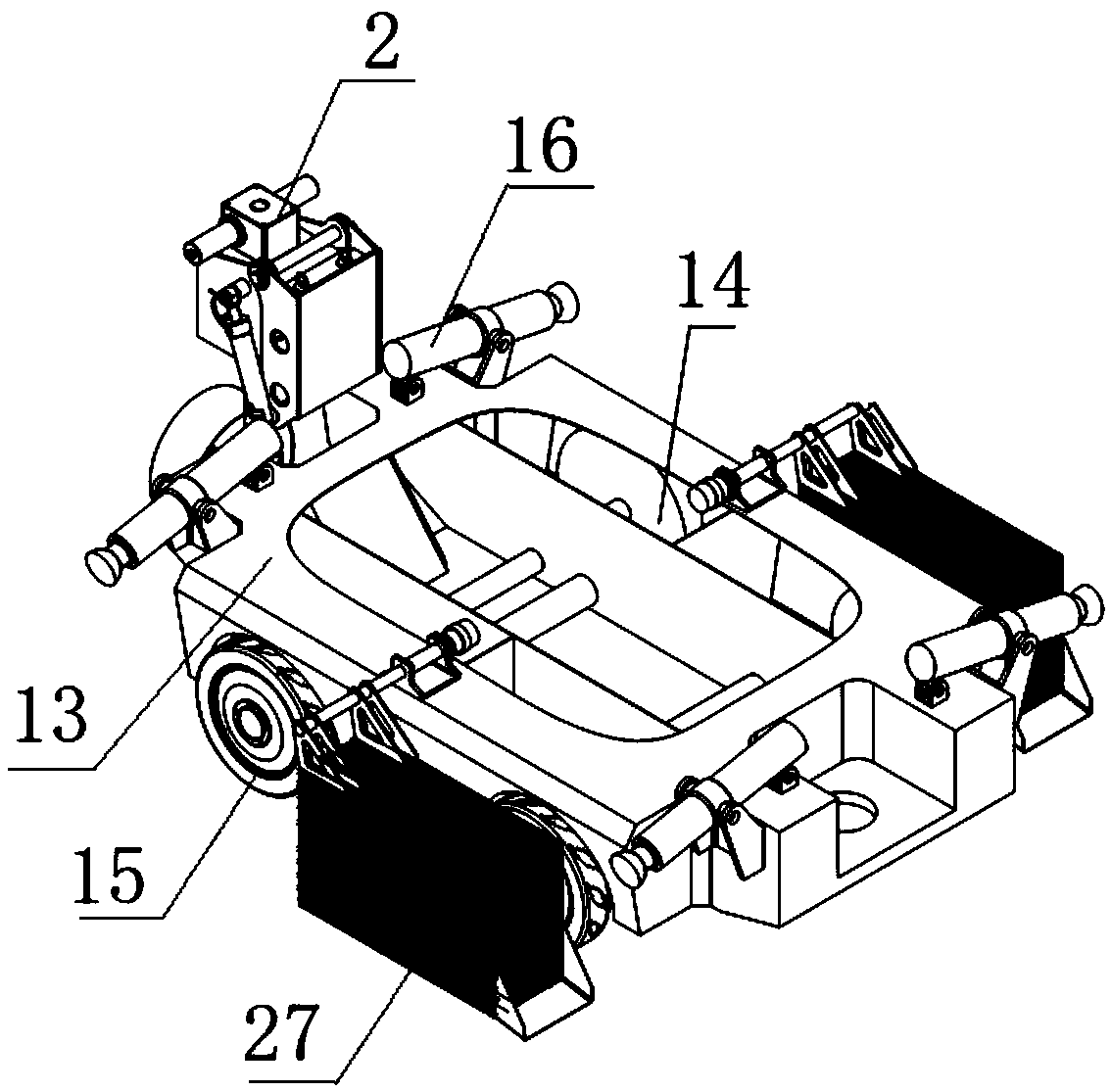

[0035] Such as figure 1 and figure 2 As shown, the dredging robot includes a platform frame 9, a hull 1, a propeller propeller 2, a left and right swinging suction mechanism 4, a dredging mechanism 7, an anti-collision guiding device 5, a pumping mechanism 3, a control unit and a vision unit. Wherein the hull 1, the propeller propeller and the anti-collision guiding device form the walking platform system, and the left and right swinging suction mechanism 4 and the dredging mechanism 7 are the execution parts.

[0036] Such as image 3 As shown, the dredging robot uses the hull 1 as the walking mechanism, and the propeller propeller 2 is installed at the tail of the hull 1, and the propeller propeller 2 provides power for the forward movement of the hull 1, that is, the hu...

Embodiment 2

[0056] On the basis of the above-mentioned embodiment 1, a cleaning system is added. The cleaning system includes a mechanical arm, a high-pressure water gun bound to the mechanical arm, and a high-pressure cleaning pump connected to the high-pressure water gun on the ground through a water pipe.

[0057] The cleaning system functions as follows:

[0058] (1) Since the existing culverts have inner chamfers, it is difficult for the dredging robot to completely clean them with the dredging mechanism. Flush and clean the silt at the inner chamfers on the left and right sides of the culvert, flush it to the center of the culvert, and then collect and pump it through the left and right swing suction mechanism 4 of the dredging robot, and pump the residual silt in the culvert to the ground in the mud-water separation equipment.

[0059] (2) When there are shellfish attached to the inner wall of the culvert, because the adhesion is not strong, the sides and top of the culvert can be...

Embodiment 3

[0062] On the basis of the above-mentioned embodiment 1, because there are shell organisms attached around the inner wall of the culvert in some areas at present, the adhesion is not strong, and the diameter is between 10-60 mm. For this special sediment, the underwater dredging robot has derived a shoveling system. Specifically, a shoveling plate is installed at the end of the five-axis robotic arm of the dredging robot, and the rotating platform under the five-axis robotic arm rotates to make the five The side wall of the culvert is vertical to the axis robotic arm, through the shovel plate installed at the front end, and then through the forward extension of the five-axis robotic arm, the shells and other attachments on the inner walls of the culvert are scraped, and finally through the left and right sides of the dredging robot Swing suction mechanism 4 collects and pumps silt and shells, and completes the dredging work in the culvert. The shell organisms at the top of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com